Rolling device and rolling method for target material

A target and rolling mill technology, applied in metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of transmission efficiency and safety to be improved, and achieve the effect of improving efficiency and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] As mentioned in the background art, the transmission efficiency and safety of the existing rolling process need to be improved.

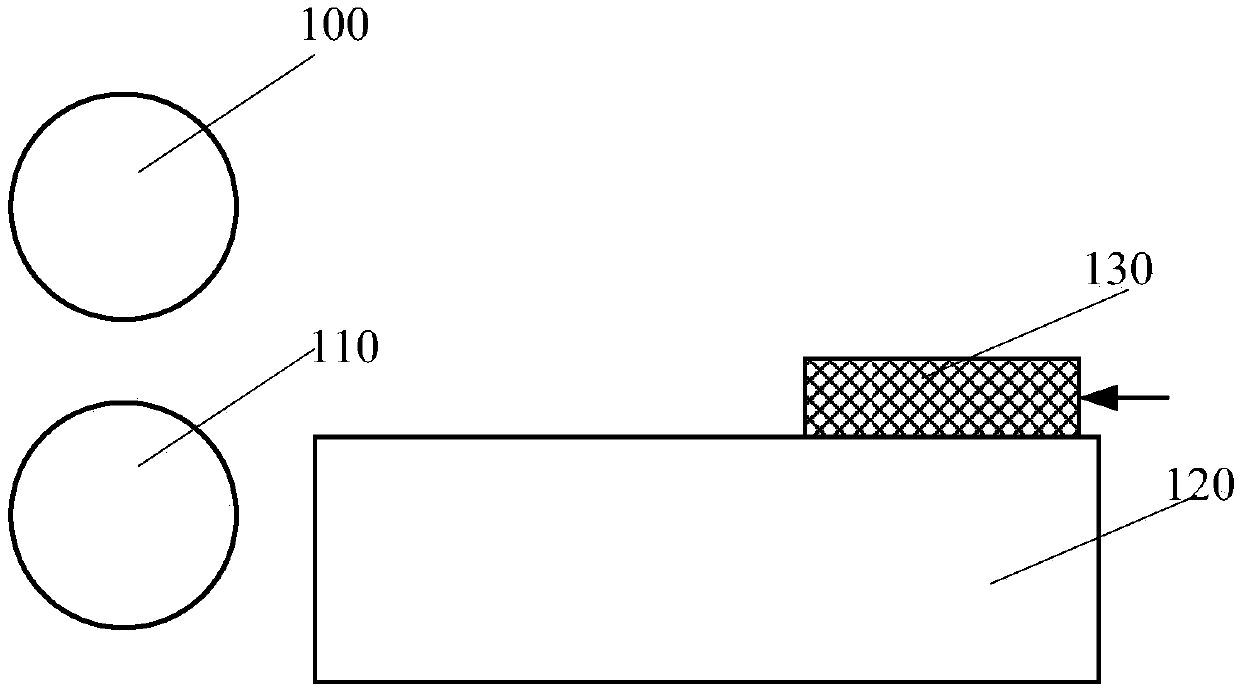

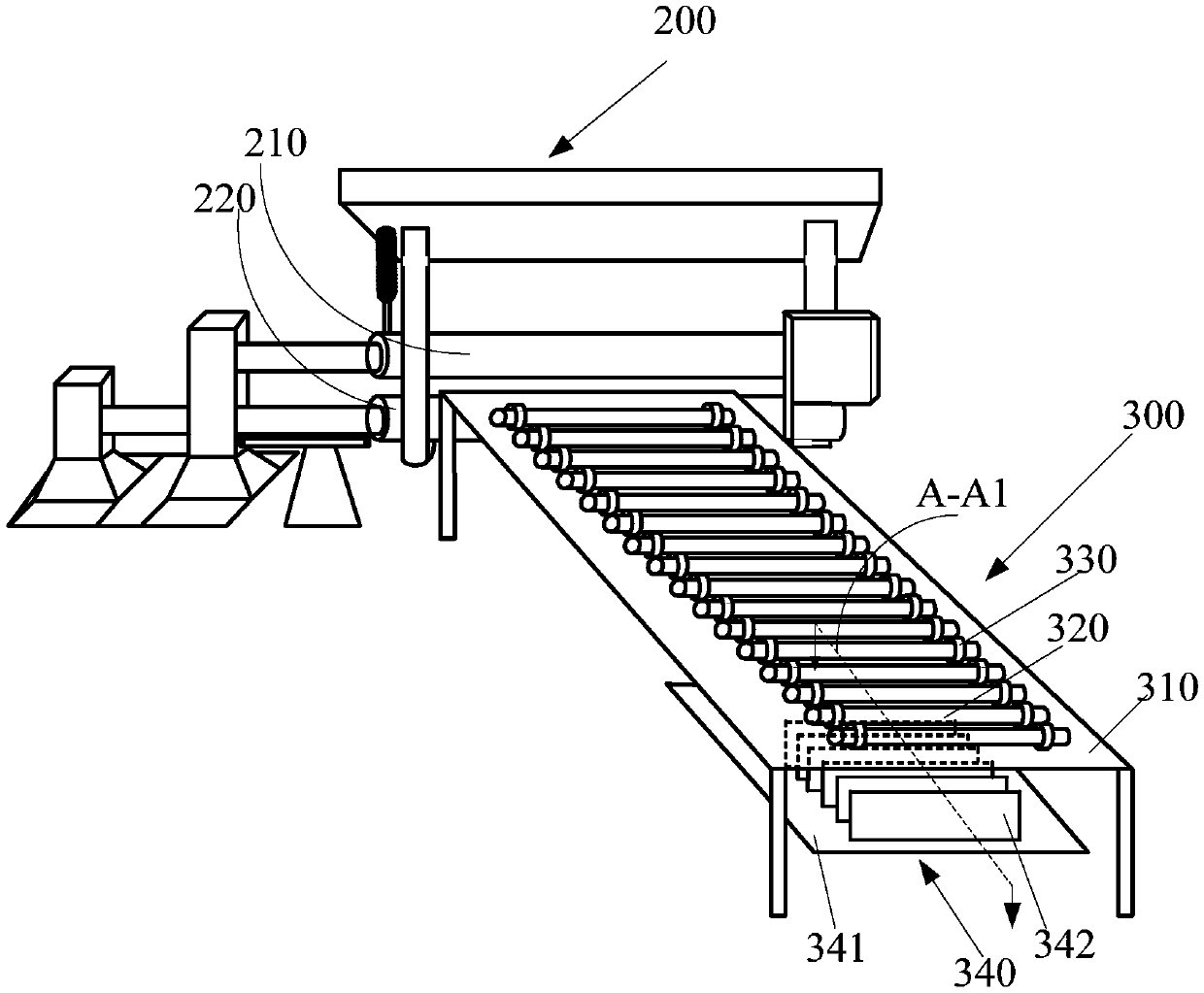

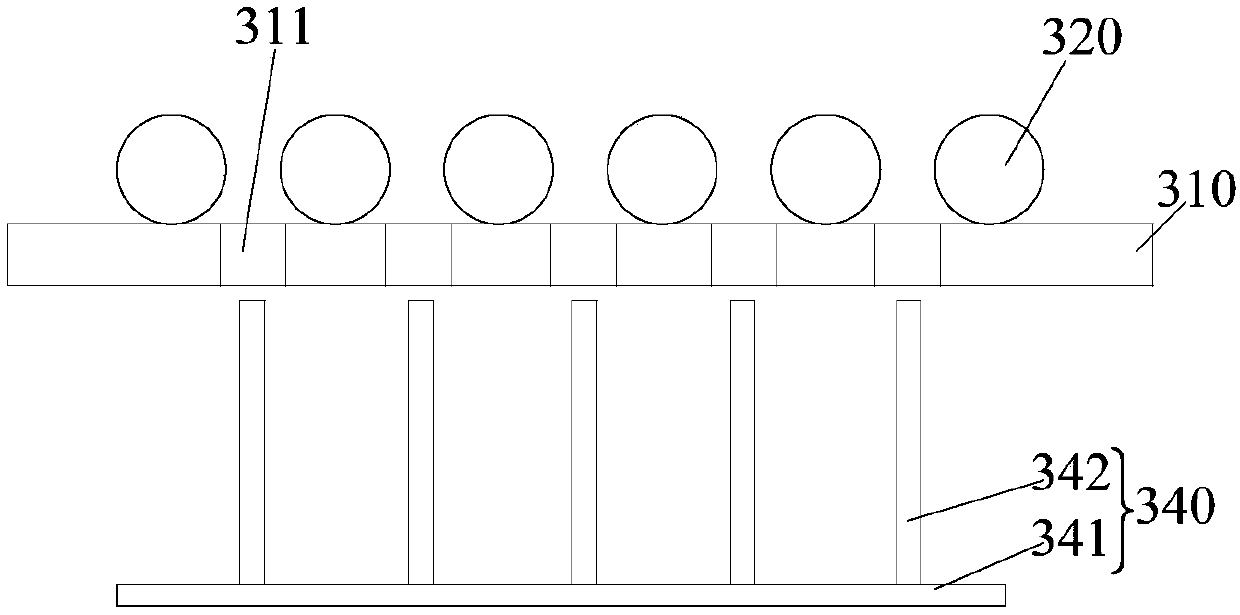

[0031] A rolling device, refer to figure 1 , including: an upper tie mix 100 and a lower tie mix 110, the upper tie mix 100 is located above the lower tie mix 110, there is a gap between the upper tie mix 100 and the lower tie mix 110; a propulsion platform 120 , the surface of the propelling platform 120 has driving rollers (not shown).

[0032] In the process of using the above-mentioned rolling device, the target material 130 is usually transported to the driving roller on the surface of the propulsion platform 120 by a forklift, and then the target material 130 is pushed to the upper and lower rolls by manually pushing the target 130. Between the mixing 110; through the rotation of the upper binding 100 and the lower binding 110, the target 130 located between the upper binding 100 and the lower binding 110 is rolled; after multiple pass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com