heteroatom nitrogen surface modification mos 2 Preparation and Application of Nanomaterials

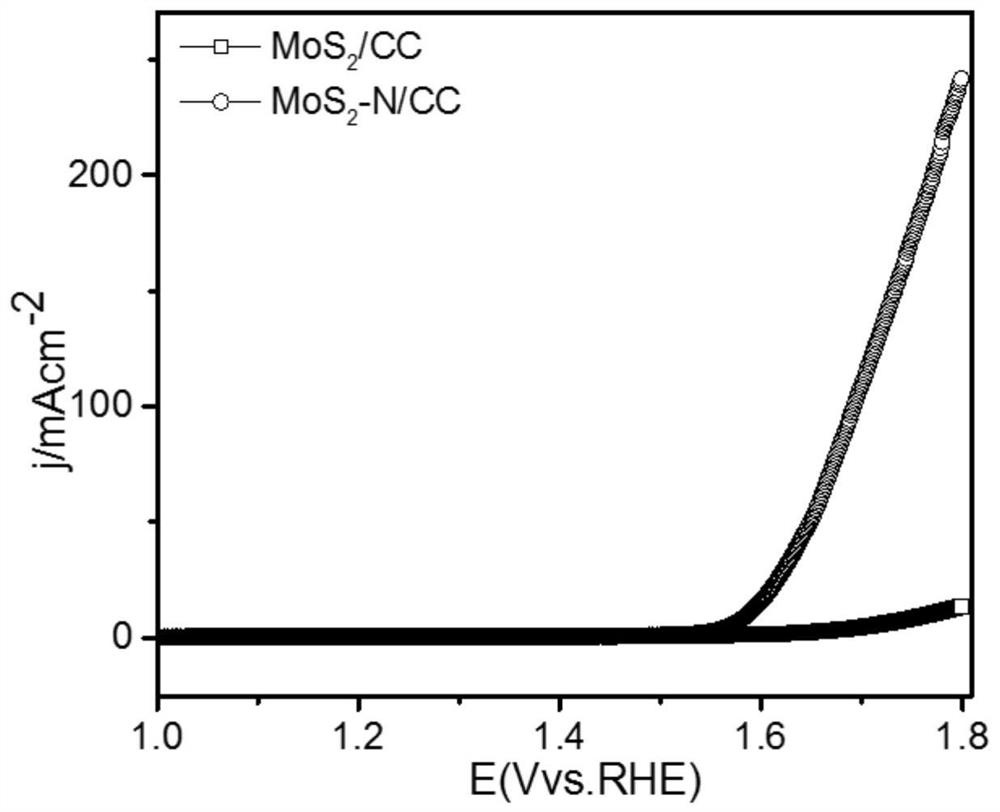

A nano-material and surface modification technology, applied in chemical/physical processes, physical/chemical process catalysts, structural parts, etc., can solve the problems of low oxygen evolution activity and complex catalyst preparation methods, and achieve simple reaction process and suitable for The effect of large-scale production and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The first step: the carbon cloth (3*3cm 2 ) in acetone, ethanol, and water for 10 minutes in sequence, and set aside;

[0024] The second step: mix ammonium molybdate and thiourea in water in proportion, wherein the molar ratio of ammonium molybdate and thiourea is 1:5, and the volume of water is 35mL and stirred until completely dissolved to obtain a uniform solution;

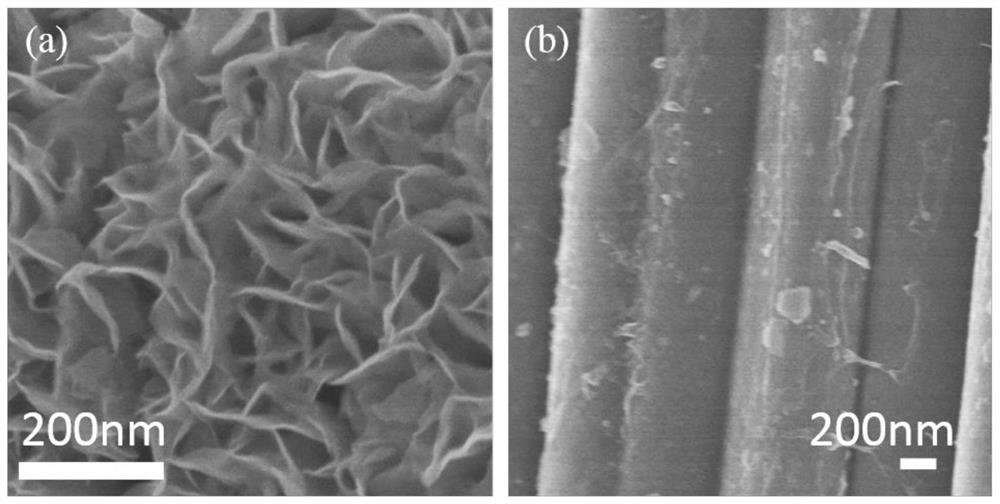

[0025] Step 3: Transfer the uniformly stirred solution to a reaction kettle with a stainless steel substrate and put it into an ultrasonically passed carbon cloth, and place the reaction kettle in a blast drying oven at 180°C for 12 hours; after cooling down to room temperature, put The carbon cloth was taken out and rinsed with ethanol and water in turn, and dried to obtain MoS 2 nanosheet catalysts.

Embodiment 2

[0027] The first step: the carbon cloth (3*3cm 2 ) in acetone, ethanol, and water for 10 minutes in sequence, and set aside;

[0028] The second step: mix ammonium molybdate and thiourea in water in proportion, wherein the molar ratio of ammonium molybdate and thiourea is 1:5, and the volume of water is 35mL and stirred until completely dissolved to obtain a uniform solution;

[0029] Step 3: Transfer the uniformly stirred solution to a reaction kettle with a stainless steel substrate and put it into an ultrasonically passed carbon cloth, and place the reaction kettle in a blast drying oven at 180°C for 12 hours; after cooling down to room temperature, put The carbon cloth was taken out and rinsed with ethanol and water in turn, and dried to obtain MoS 2 nanosheet catalysts.

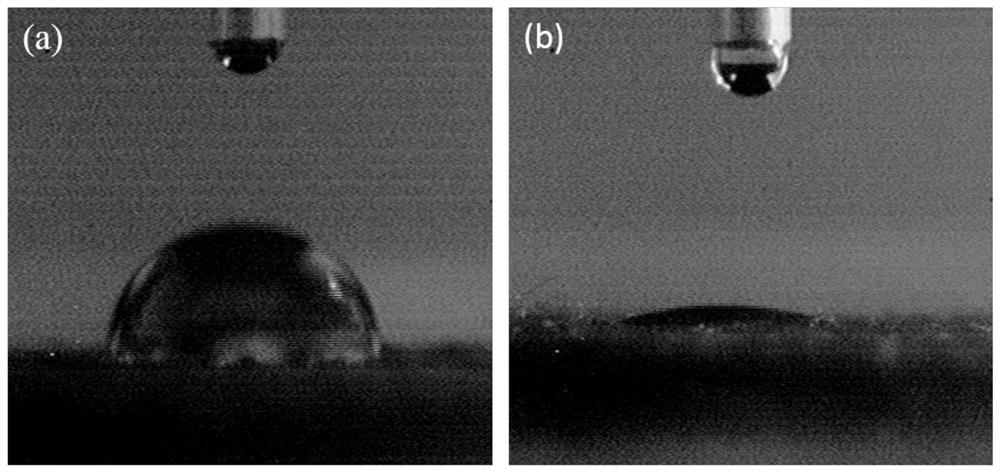

[0030] In the fourth step, 10mL of ammonia water is placed in the reactor, and the MoS 2 The nanosheets are placed above the ammonia water without contact with the ammonia water, and the reaction kett...

Embodiment 3

[0032] The first step: the carbon cloth (3*3cm 2 ) in acetone, ethanol, and water for 10 minutes in sequence, and set aside;

[0033] The second step: mix ammonium molybdate and thiourea in water in proportion, wherein the molar ratio of ammonium molybdate and thiourea is 1:5, and the volume of water is 35mL and stirred until completely dissolved to obtain a uniform solution;

[0034] Step 3: Transfer the uniformly stirred solution to a reaction kettle with a stainless steel substrate and put it into an ultrasonically passed carbon cloth, and place the reaction kettle in a blast drying oven at 180°C for 12 hours; after cooling down to room temperature, put The carbon cloth was taken out and rinsed with ethanol and water in turn, and dried to obtain MoS 2 nanosheet catalysts.

[0035] In the fourth step, 5mL of ammonia water is placed in the reactor, and the MoS 2 The nanosheets are placed above the ammonia water without contact with the ammonia water, and the reaction kettl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com