Arrangement method of reaction kettle steam drum and related pipelines

An arrangement method and technology of reactors, applied in chemical/physical/physical-chemical fixed reactors, etc., can solve the problems of low valve efficiency, inability to optimize workshop layout, pipeline length, etc., and reduce the probability of misoperation of valves, Reduce leakage of frozen brine, high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

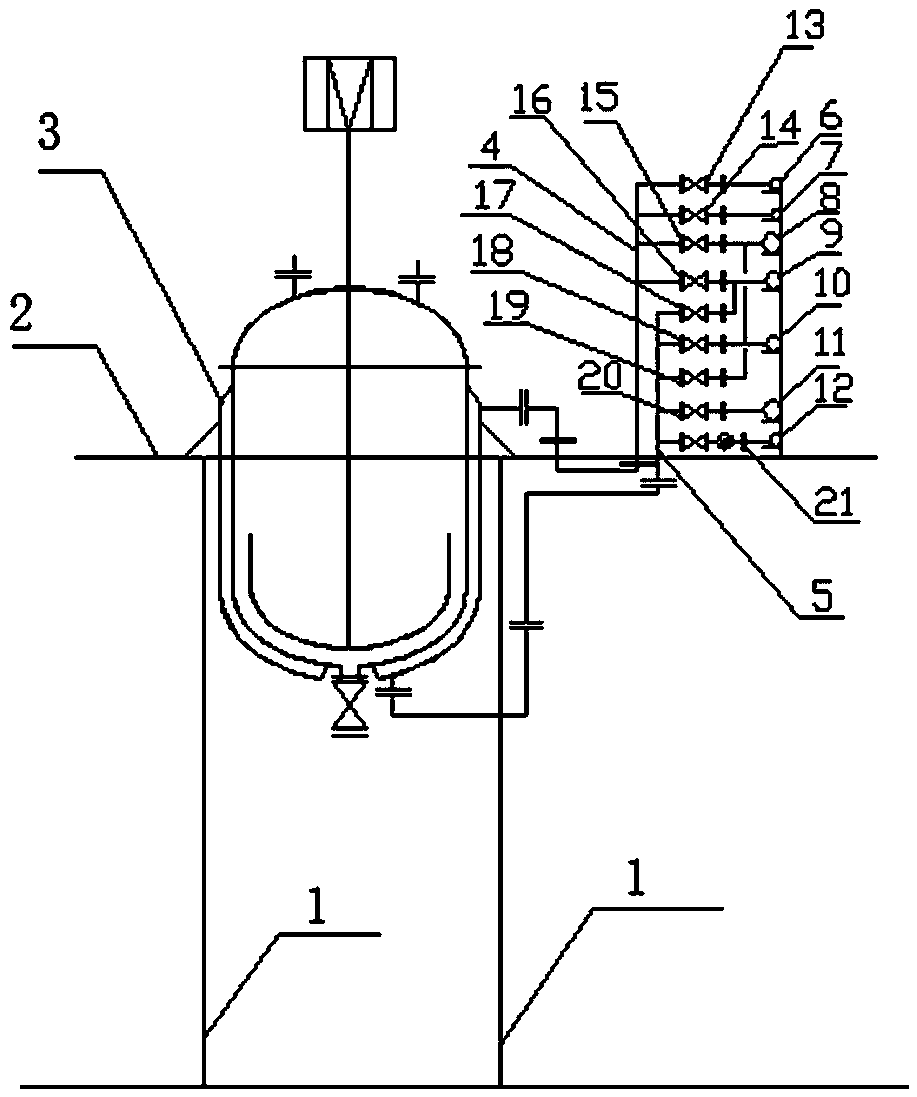

[0058] Such as figure 1 As shown, it is a steam drum structure designed according to the layout method of the reactor drum and related pipelines, which is heated by steam, cooled by cooling water and cooled by frozen brine:

[0059] The most basic feature of the steam drum designed by the layout method of the reactor steam drum and related pipelines is that the "upper steam drum" 4 and the "lower steam drum" 5 contained in the "steam drum" of the reactor jacket are perpendicular to the workshop operation platform 2 or a substantially vertical angle, and the "upper steam drum" 4 and the "lower steam drum" 5 are staggered and installed independently; the control valves connected to the upper and lower steam drums are installed at an angle parallel or substantially parallel to the workshop operation platform; "SAIC Package "4 and "lower steam drum" 5 are basically parallel to the workshop operation platform, and are all on the same workshop operation platform.

[0060] The work...

Embodiment 2

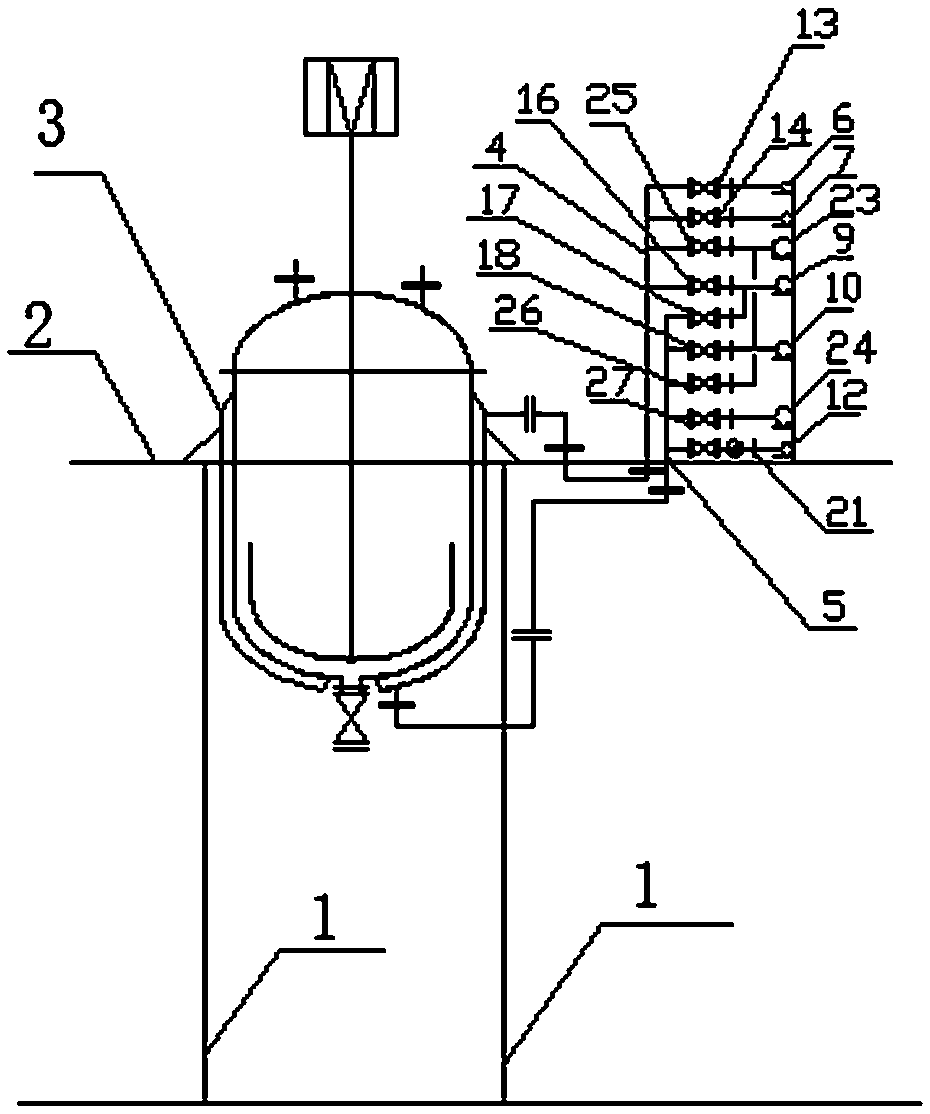

[0085] Such as figure 2 As shown, it is a steam drum structure designed according to the arrangement method of the reactor steam drum and related pipelines, which can be heated by steam, heated by hot water, and cooled by frozen brine.

[0086] The upper steam drum and the lower steam drum are basically perpendicular to the workshop operation platform, and the upper and lower steam drum control valves or valve groups and connecting pipes and corresponding utility pipelines are basically parallel to the workshop operation platform, and are all on the same workshop operation platform. Or the relative installation height of the valve group and the corresponding public engineering pipeline can be referred to the following table:

[0087] If the volume of the reactor in the workshop operation platform is not greater than 6300L, the steam drum can be designed and installed with reference to the following data:

[0088]

[0089] The workshop reaction kettle 3 is installed on the...

Embodiment 3

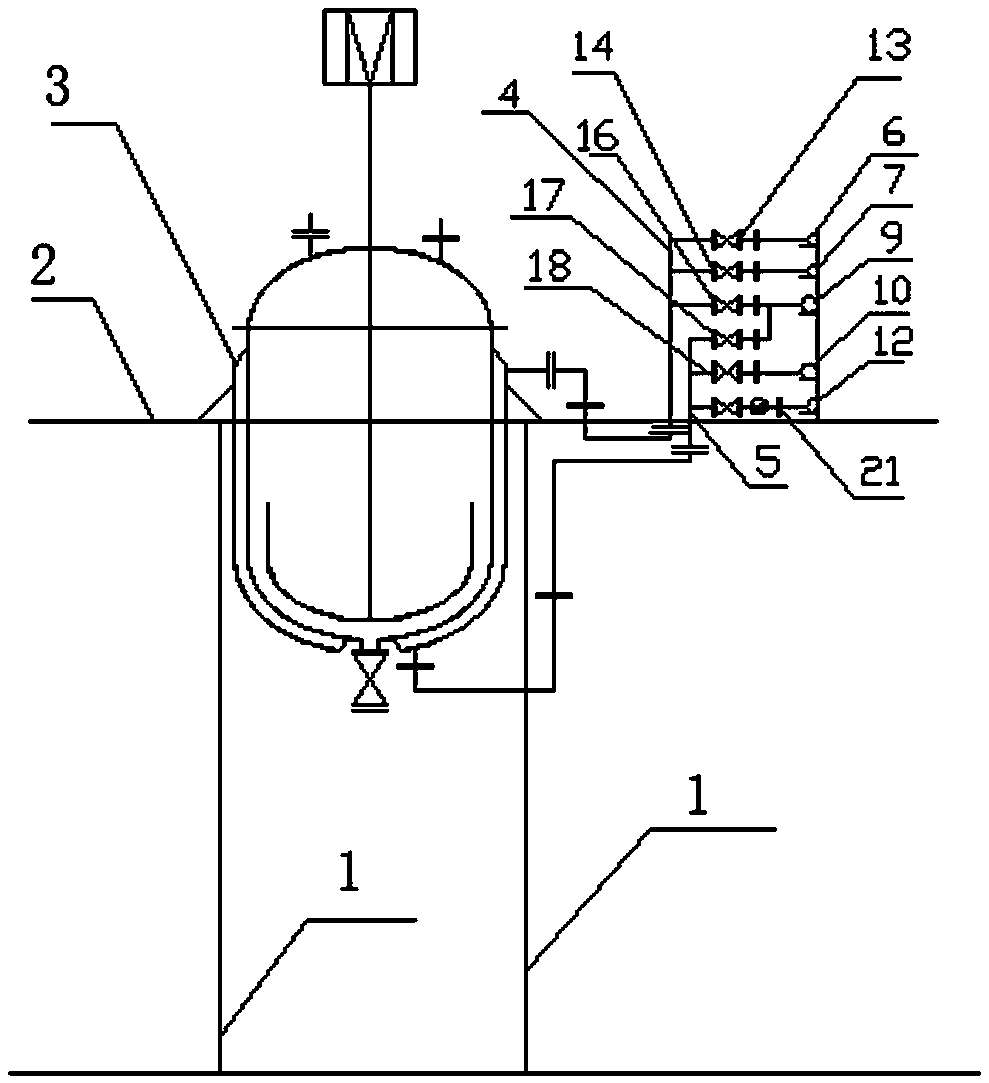

[0092] Such as image 3 As shown, it is a steam drum structure designed according to the arrangement method of the reactor steam drum and related pipelines, which is heated by steam and cooled by frozen brine.

[0093] The upper steam drum and the lower steam drum are perpendicular to the workshop operation platform, the upper and lower steam drum control valves or valve groups and connecting pipes and the corresponding utility pipelines are basically parallel to the workshop operation platform, and are all on the same workshop operation platform, and the steam drum valves or The relative installation height of the valve group and the corresponding public engineering pipeline can be referred to the following table:

[0094] If the volume of the reactor in the workshop operation platform is not greater than 6300L, the steam drum can be designed and installed with reference to the following data:

[0095]

[0096] The workshop reaction kettle 3 is installed on the workshop o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com