A full speed domain model predictive flux linkage control method for permanent magnet synchronous motors

A technology of permanent magnet synchronous motor and control method, which is applied in the direction of motor generator control, electronic commutation motor control, control system, etc., can solve problems such as unconsidered current and torque ripple, achieve good dynamic steady-state performance, reduce Effect of Current and Torque Ripple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further explained below in conjunction with the accompanying drawings.

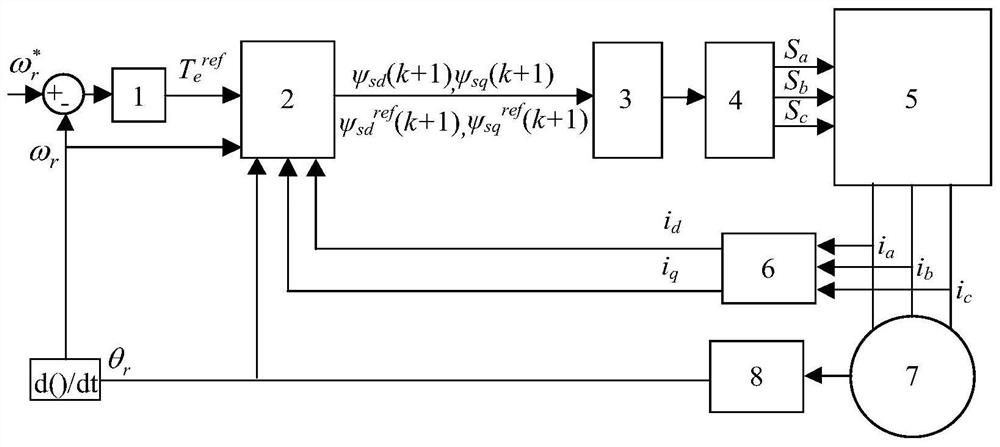

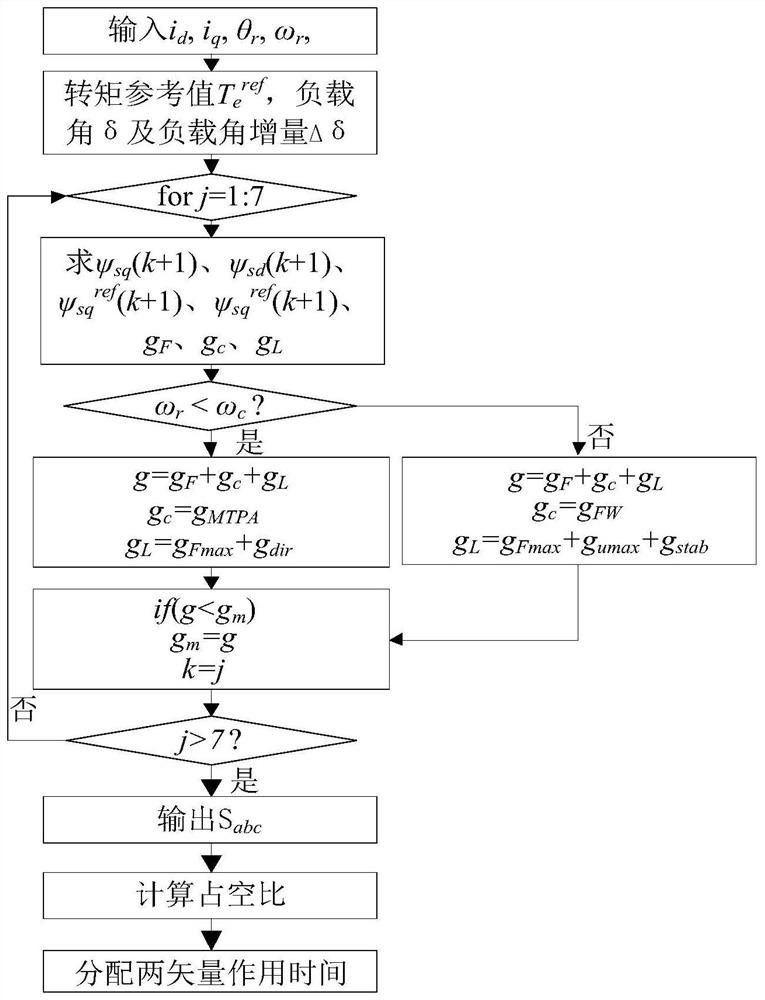

[0049] The schematic diagram of a permanent magnet synchronous motor full-speed domain model predictive flux linkage control method is as follows: figure 1 As shown, it includes speed PI controller 1, model prediction flux linkage control module 2, full-speed domain value function module 3, duty cycle calculation module 4, inverter 5, coordinate transformation module 6, permanent magnet synchronous motor 7 and encoder 8.

[0050] First, the reference torque T is obtained through the speed outer loop PI controller e ref ; Then get the electrical angle θ of the permanent magnet synchronous motor from the motor encoder r and electrical angular velocity ω r , and use the current sensor to obtain the three-phase stator current i at time k a , i b and i c , after coordinate transformation, the d-q axis component i of the stator current at time k is obtained d and i ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com