Portable multifunctional optical cable welding box

A multi-functional and portable technology, applied in the direction of light guide, optics, optical components, etc., can solve the problems of cumbersome optical cable welding platform, no unified storage device, and increase the difficulty of finding, so as to reduce the difficulty of handling and work intensity, and save materials. time, saving pick-and-place time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

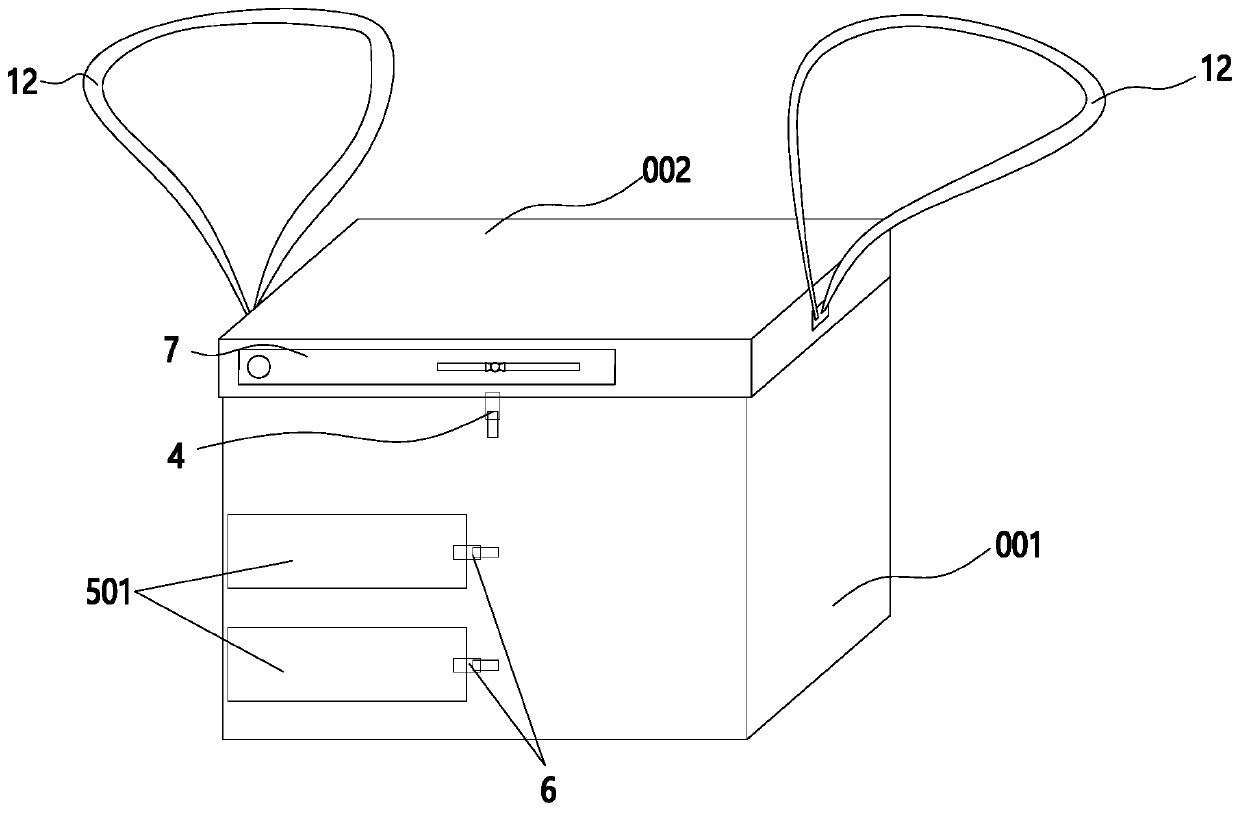

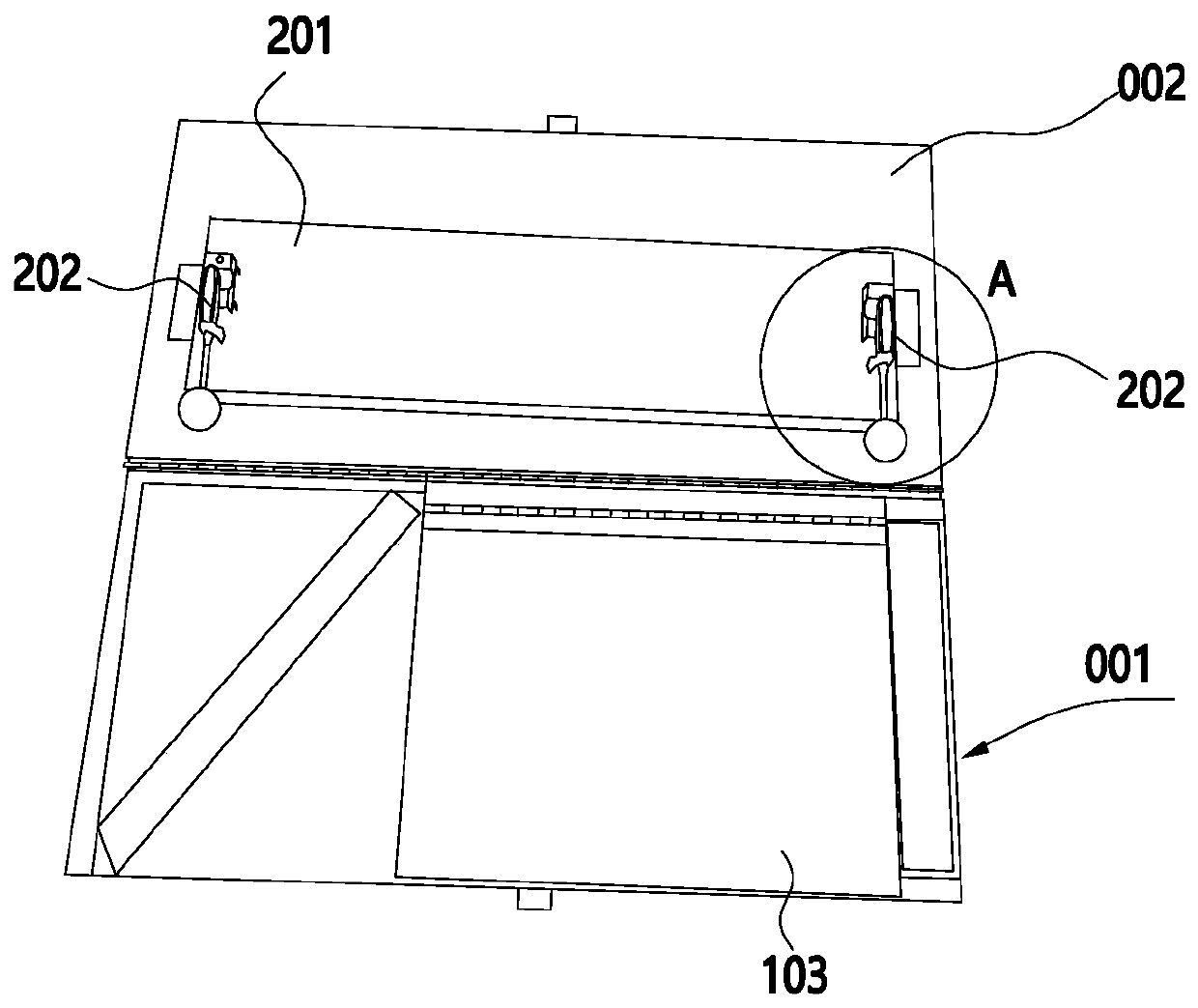

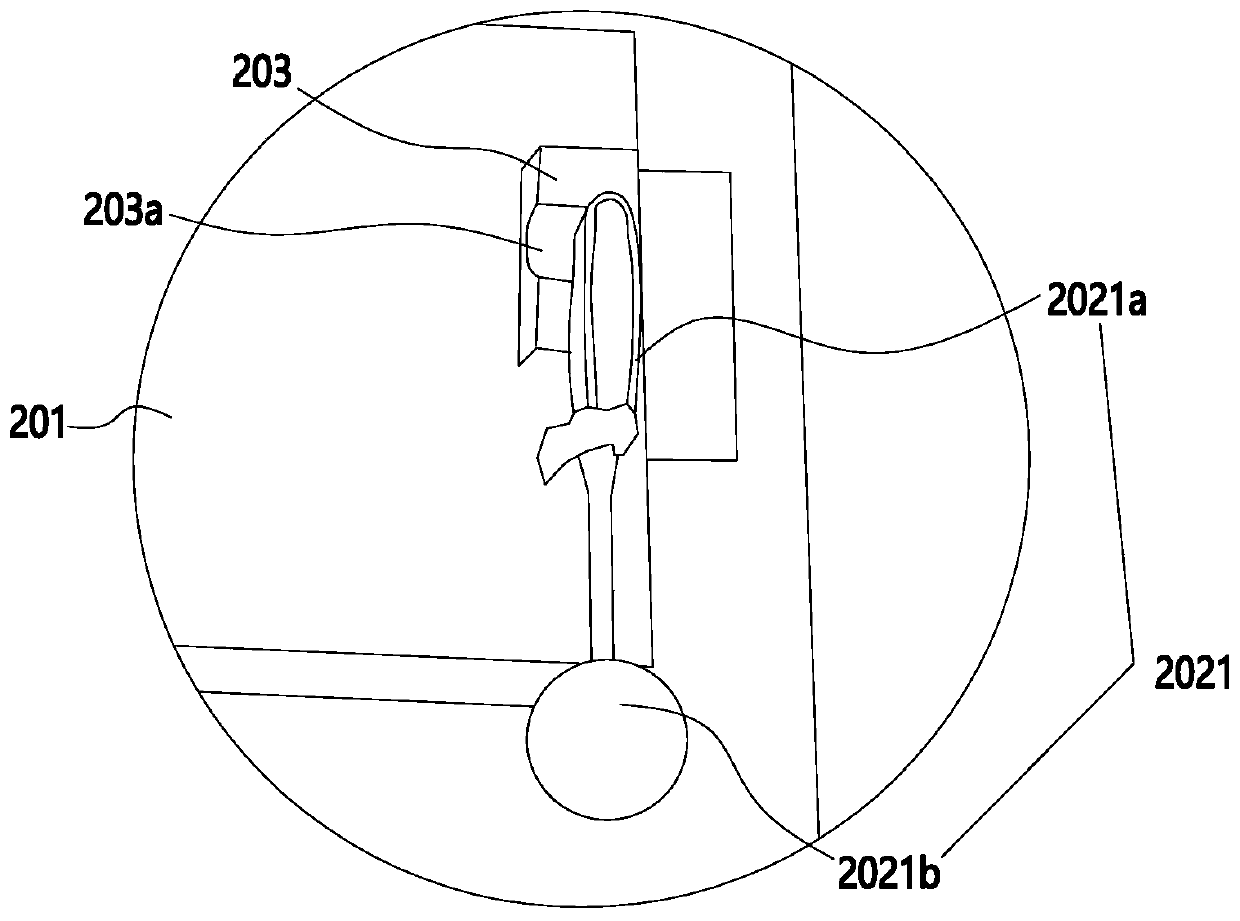

[0034] Such as Figure 1 to Figure 7 As shown, a portable multifunctional optical cable fusion splicing box includes a lower box body 001 and a box cover 002 hinged on the lower box body 001. A first operating platform 201 is provided on the inside of the box cover 002, and the two ends of the first operating platform 201 are provided with There is an optical cable clamping mechanism 202, and the lower box body 001 is provided with an accommodation cavity 101 for accommodating the optical cable welding machine. The opening of the accommodation cavity 101 is upward, and a movable cover 103 is hinged above the accommodation cavity 101, and the movable cover 103 forms a second operating platform. When placing the optical cable fusion splicer, open the movable cover 103 and put it into the accommodation cavity 101. The fusion splicing box includes the storage mode in which the box cover 002 is closed on the lower box body 001 and the use mode after the box cover 002 is opened. In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com