Method for measuring plastic strain ratio in metal tensile test process

A technology of plastic strain ratio and tensile test, which is used in measuring devices, using stable tension/pressure to test the strength and strength characteristics of materials, etc., can solve the problems of mechanical properties, measurement accuracy errors, etc. Small, reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

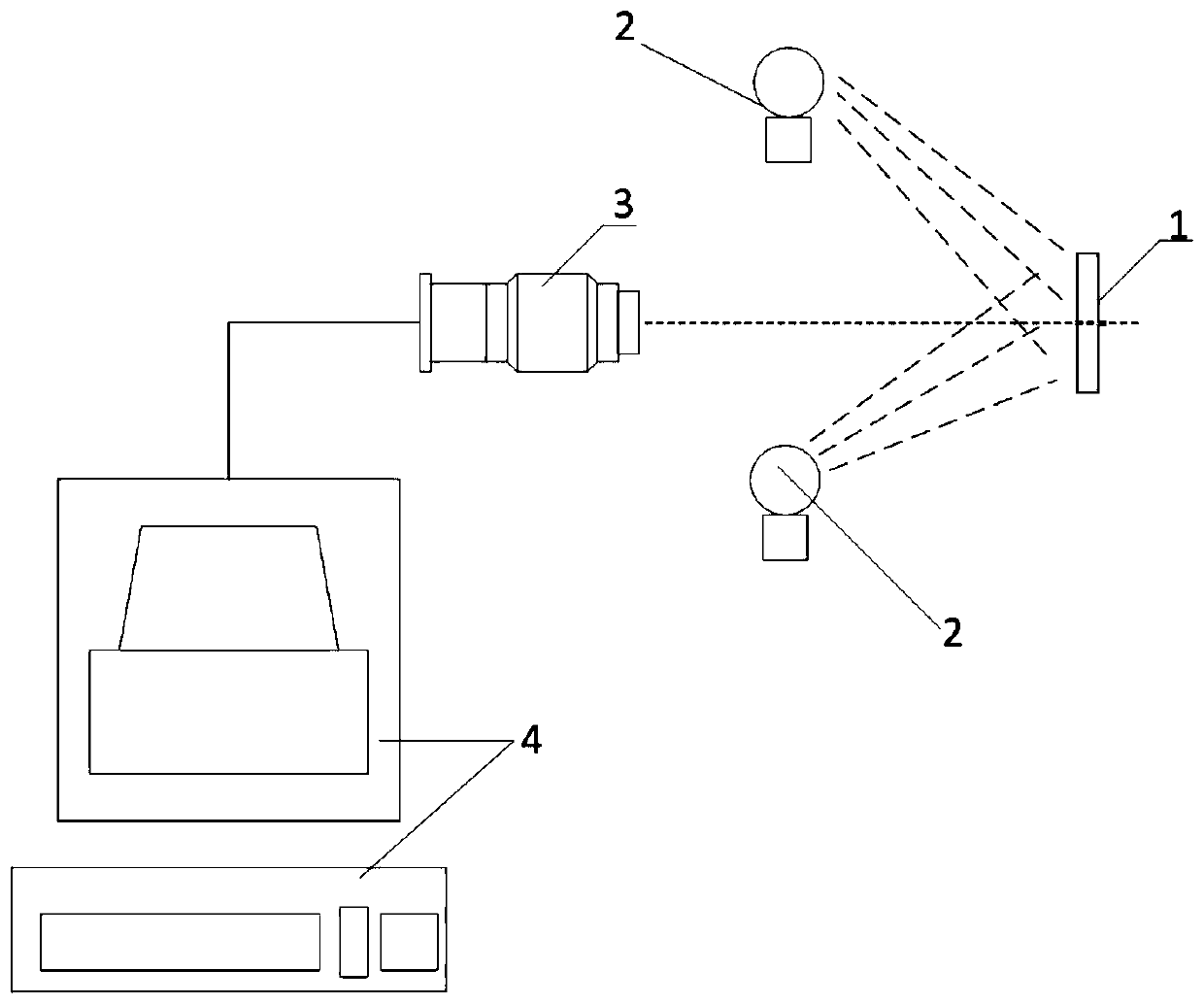

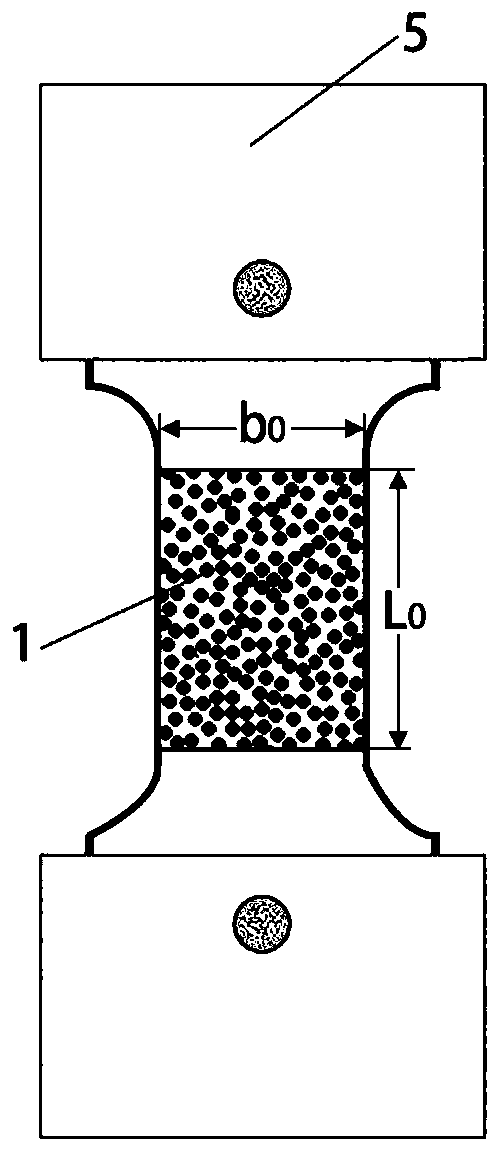

[0025] The device platform used in this embodiment is as figure 1 and figure 2 As shown, the symmetrical light source 2 is projected on the surface of the sample to be tested, and the CCD industrial camera 3 is aimed at the gauge area where speckle spots are arranged in the center of the tensile sample 1 , and the image data collected by the CCD industrial camera 3 is stored in the data collector 4 .

[0026] The method for measuring the plastic strain ratio in the metal tensile test process of the present embodiment comprises the following steps:

[0027] The first step is to uniformly spray a layer of white spray paint on one side of the surface of the metal sample as the base, and after the white spray paint dries, arrange a plurality of black speckle spots on the base of the gauge area, thereby making tensile sample 1.

[0028] Usually, the stamp tool can be used to arrange speckle spots in the gauge area of the metal sample, and the size of each speckle spot is about ...

Embodiment 2

[0054] This embodiment is a further improvement on the basis of Embodiment 1, and the difference from Embodiment 1 is:

[0055] 1) In the third step, multiple images of the gauge length region in the uniform plastic deformation stage of the tensile specimen are collected, and a uniform plastic deformation image sequence is formed in time order, and then the first image in the uniform plastic deformation image sequence is taken as the second image ;

[0056] 2) After the sixth step is executed, the first image remains unchanged, and the next image in the uniform plastic deformation image sequence is used as the second image, and then the fourth to sixth steps are repeated until the calculation of the uniform plastic deformation is completed All images in the image sequence, resulting in multiple plastic strain ratios;

[0057] 3) Take the average value of all the plastic strain ratios as the plastic strain ratio of the metal sample.

[0058] In order to ensure that the test r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com