Platform device and flatness detection and adjustment equipment

A carrier platform and bearing surface technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve problems such as difficulty in ensuring flatness, unfavorable target operation, and target warping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

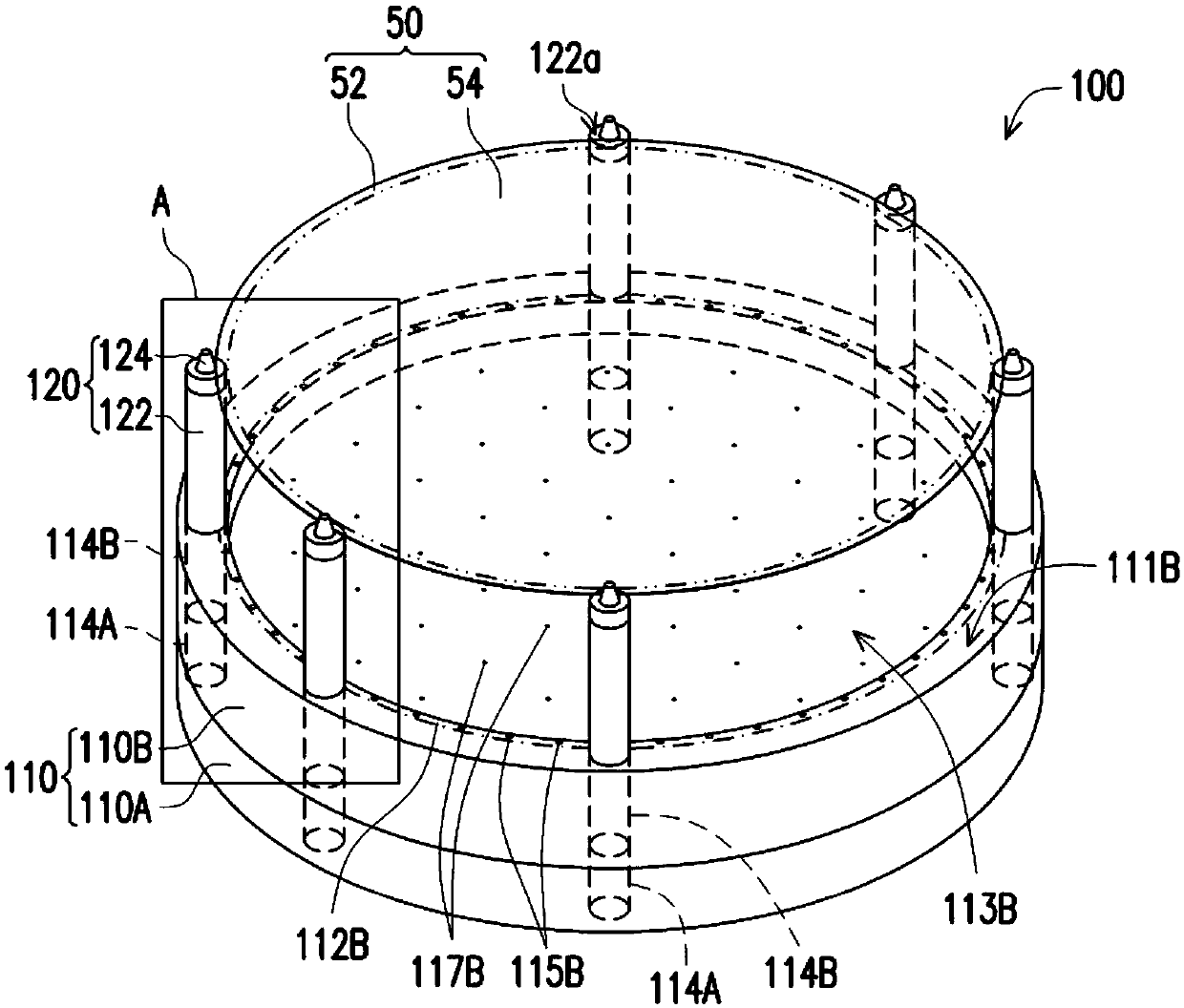

[0041] For clarity and ease of explanation, the figure 1 , Figure 2A , Figure 2B as well as Figure 2C The first through hole 114A of the first seat portion 110A and the second through hole 114B of the second seat portion 110B are shown in dashed lines. exist figure 1 , Figure 2A as well as Figure 2B The boundary of the adsorption region 112B of the second seat portion 110B on the first bearing surface 111B is shown by a dot chain line. exist Figure 2A , Figure 2B as well as Figure 2C The dotted line shows the structure behind the target 50 , and the boundary between the outer edge portion 52 and the middle portion 54 of the target 50 is shown by a chain line of two dots.

[0042] Please refer to figure 1 , the stage device 100 includes a base 110 assembled and fixed by the first seat part 110A and the second seat part 110B (for example, assembled and fixed by screws), and is used to carry such as Figure 2A Lift assembly 120 of target 50 is shown. The shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com