Method for open-air deep-hole bench pre-cracking hole hole-by-hole detonation pre-cracking blasting cracking in complex environment

A complex environment, pre-splitting blasting technology, applied in blasting and other directions, can solve the problems of high degree of weathering, high drop, steep slope angle, etc., and achieve the effect of good stability, small vibration and small disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

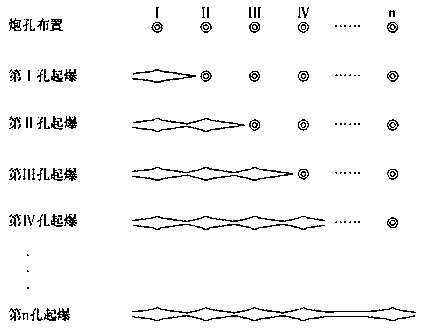

[0036] Example 1: Such as Figure 1~4 As shown, a method for forming joints by hole-by-hole initiation and pre-split blasting in open-air deep-hole bench pre-split holes in a complex environment is as follows:

[0037] A method for forming joints by hole-by-hole initiation and pre-split blasting in open-air deep-hole bench pre-split holes in complex environments, the specific steps are as follows:

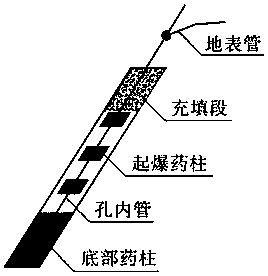

[0038] (1) The inclined pre-split holes are evenly arranged on the contour line of the open-air deep-hole step excavation foundation pit under the complex design environment, and the axially uncoupled air gap charge device is set in the pre-split holes; the complex environment is that there are residential buildings, Cultural relics and other surrounding structures, etc. The hole diameter of the pre-split holes is 50~200mm, and the hole spacing of the pre-split holes is 8~12 times the diameter of the pre-split holes. The rock mass is intact as the larger value, and the rock mass is bro...

Embodiment 2

[0051] Embodiment 2: The complex environment of this embodiment is the current status of the application of pre-split blasting in the Yunnan Hualian zinc-indium open-pit mine;

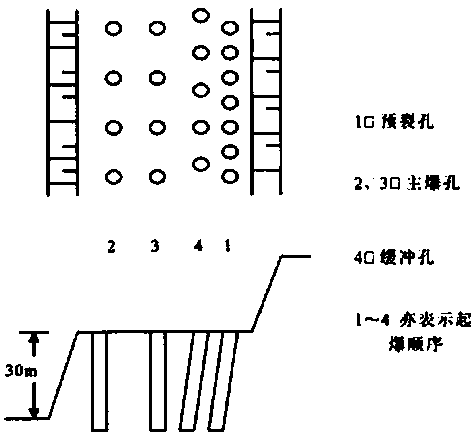

[0052] The method of step-by-hole initiation and pre-split blasting of open-air deep-hole step pre-split holes in complex environments is basically the same as that in Example 1, except that the hole diameter of the pre-split holes is 120mm, and the hole spacing of the pre-split holes is 8 times the diameter of the pre-split holes , The delay time of the digital electronic detonator of the pre-split hole is 12ms; the horizontal distance between the pre-split hole and the main blast hole of the adjacent row is 4.4m, and the horizontal distance between the pre-split hole and the main blast hole of the adjacent row is 2m; The hole diameter is 140mm, the distance between the buffer hole and the pre-split hole is 4.4m, and the pitch of the buffer hole is 5m; the bottom of the buffer hole is filled with loose sl...

Embodiment 3

[0053] Embodiment 3: The complex environment of this embodiment is the use of hole-by-hole initiation of open-pit steps in a mine;

[0054] The method of step-by-hole initiation and pre-split blasting of open-air deep-hole step pre-split holes in complex environments is basically the same as that in Example 1, except that the hole diameter of the pre-split holes is 120mm, and the hole spacing of the pre-split holes is 10 times the diameter of the pre-split holes. , The delay time of the digital electronic detonator of the pre-split hole is 12ms; the horizontal distance between the pre-split hole and the main blast hole of the adjacent row is 3m, and the horizontal distance between the pre-split hole and the main blast hole of the adjacent row is 2.5m; The hole diameter of the buffer hole is 120mm, the distance between the buffer hole and the pre-split hole is 3m, and the pitch of the buffer hole is 4m; the bottom of the buffer hole is filled with loose slag with a height of 1.5m, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com