Oil pressure circuit of transmission

A transmission and oil pressure technology, applied to components with teeth, transmission parts, belts/chains/gears, etc., can solve problems such as internal pressure drop, oscillation, etc., and achieve the effect of preventing insufficient oil pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

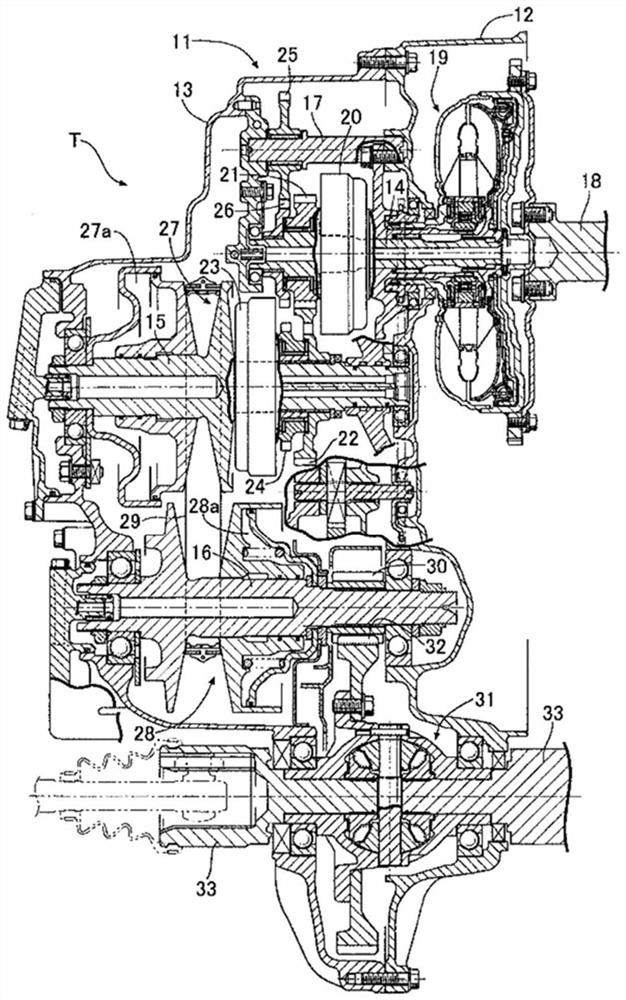

[0102] Hereinafter, embodiments of the present invention will be described with reference to the drawings. figure 1 It is a longitudinal cross-sectional view of a belt-type continuously variable transmission mechanism, which is one form of the transmission of the present invention. First, use figure 1 , the overall structure of the belt-type continuously variable transmission T is described. The transmission case 11 of the belt-type continuously variable transmission T includes a torque converter case 12 to which an engine (not shown) is coupled, and a transmission case body 13 to which the torque converter case 12 is coupled. , the input shaft 14 , the drive pulley shaft 15 , the driven pulley shaft 16 and the idle shaft 17 are supported in parallel.

[0103] On the input shaft 14 connected to the crankshaft 18 of the engine via the torque converter 19, a forward drive gear 21 which can be coupled to the input shaft 14 via the forward clutch 20 is relatively rotatably suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com