Three-freedom parallel vibration isolating platform with quasi-zero stiffness characteristic

A quasi-zero stiffness, vibration isolation platform technology, applied in non-rotational vibration suppression, geometric CAD and other directions, can solve the problems of small working space, complex structure, and reduced platform vibration isolation performance, and achieve simple and compact structure and flexible motion characteristics. , the effect of good vibration isolation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention is further described below in conjunction with specific embodiment, but protection scope of the present invention is not limited thereto:

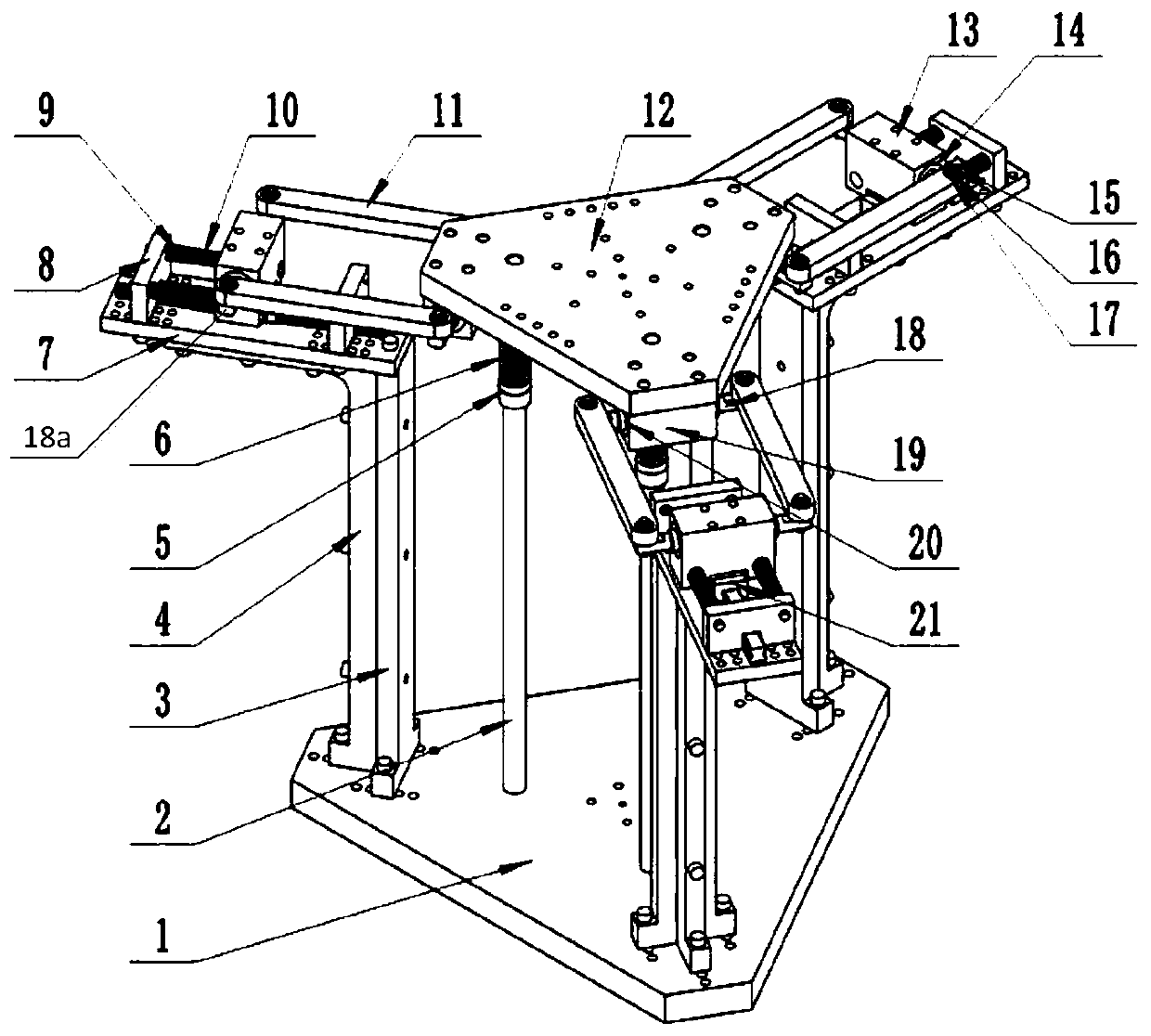

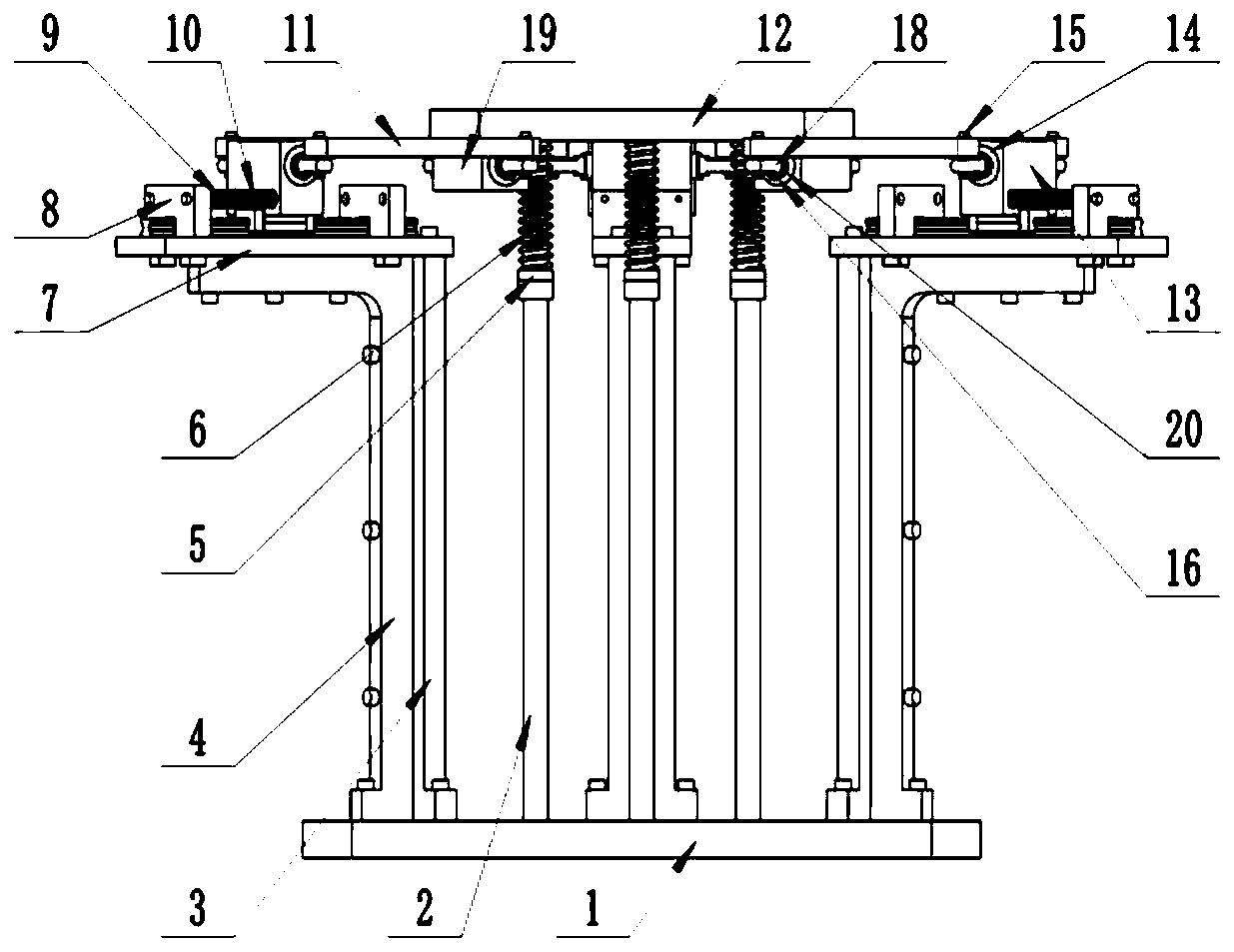

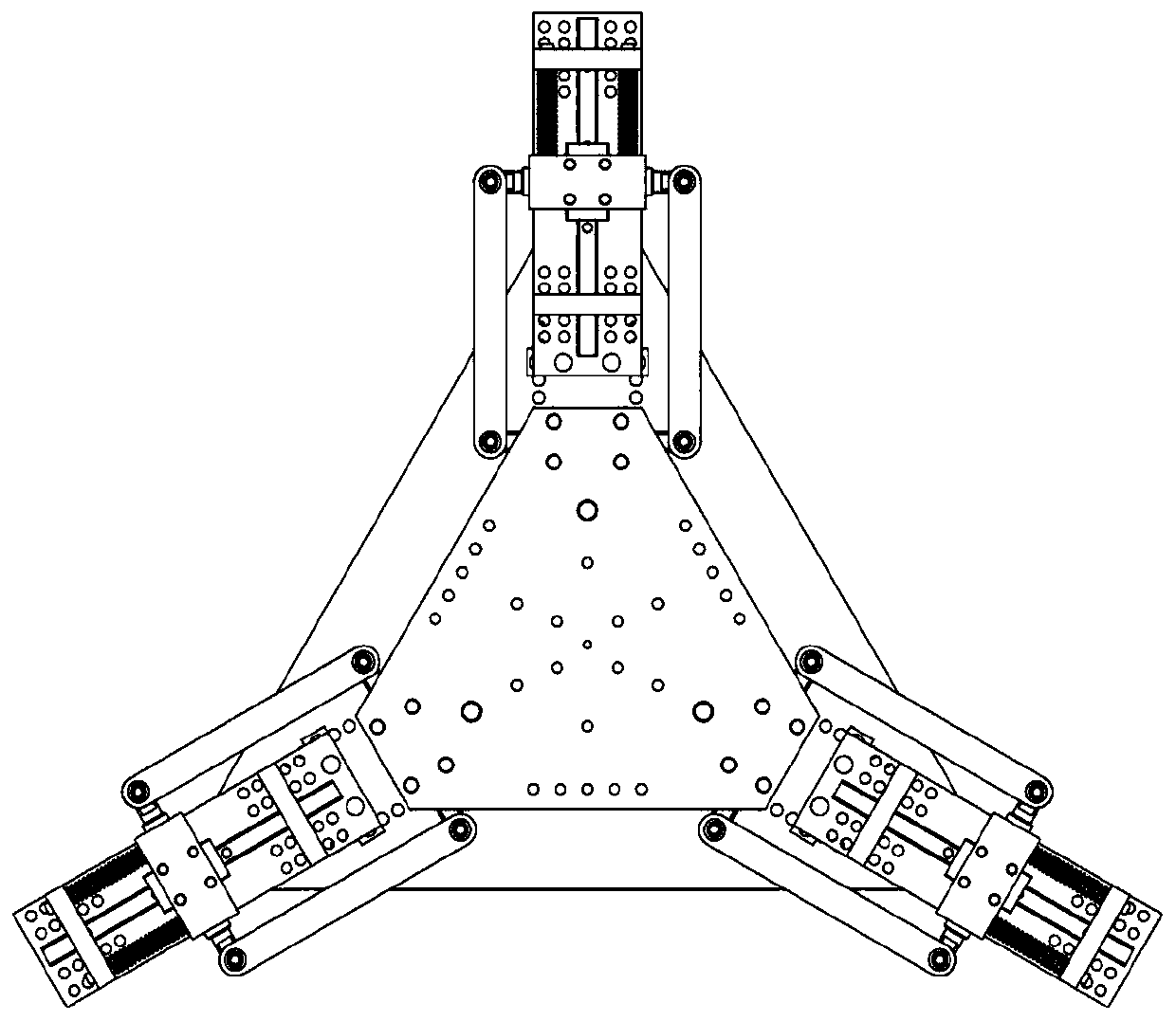

[0033] Referring to the accompanying drawings, a three-degree-of-freedom parallel vibration isolation platform with quasi-zero stiffness characteristics includes a static platform connected to an external foundation platform, a dynamic platform carrying vibration-isolated equipment, a branch chain, and a quasi-zero stiffness mechanism;

[0034] Both the bottom plates of the static platform and the dynamic platform are in the shape of flat plates arranged horizontally, and the bottom plate 12 of the dynamic platform is connected with a branch chain every 120 degrees radially from the centroid to the center of the circle, and the branch chain is erected on the support frame bottom plate 7 of the static platform. Described radial direction constitutes the shape symmetry line of moving platform base plate 12; In descr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com