Rapid hole sealing device and method

A sealing device and fast technology, applied in safety devices, sealing/isolation, earthwork drilling, etc., can solve the problems of difficult to control the insertion time, gas can not be discharged, waste of chemicals, etc., to achieve convenient operation, convenient combination, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

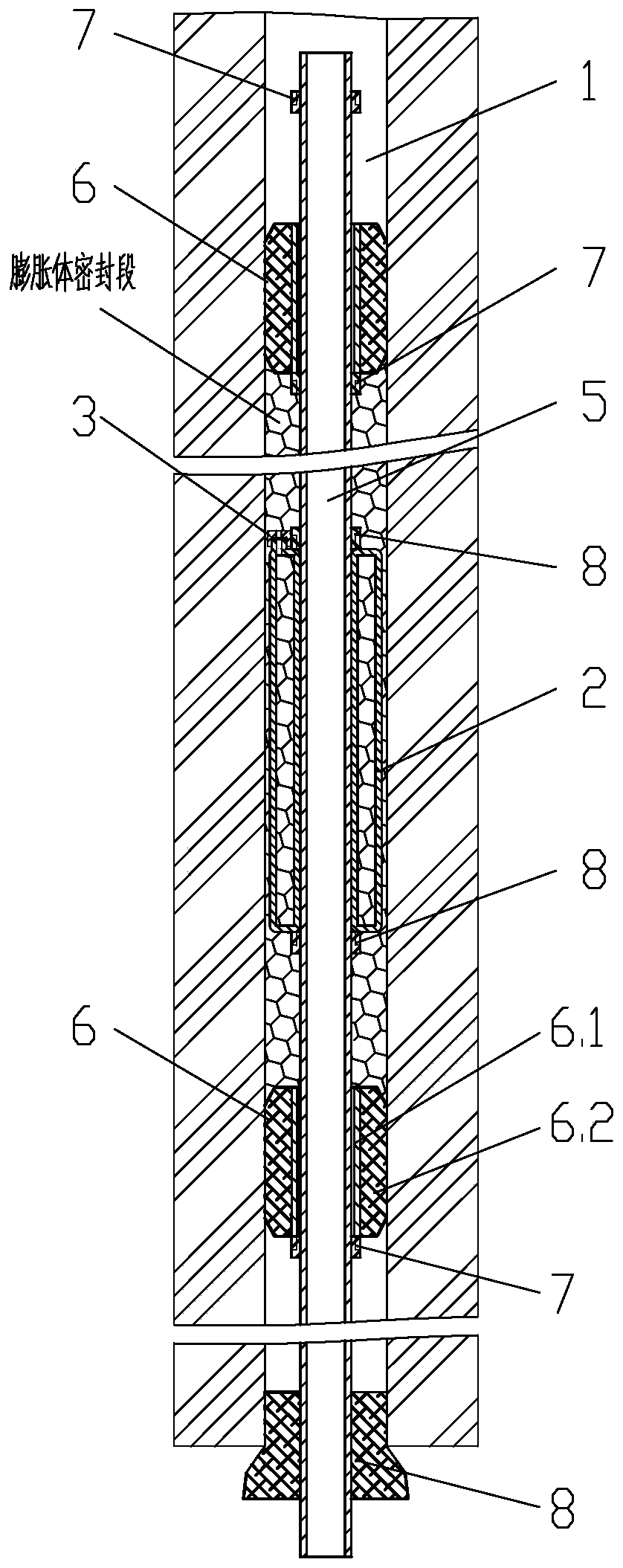

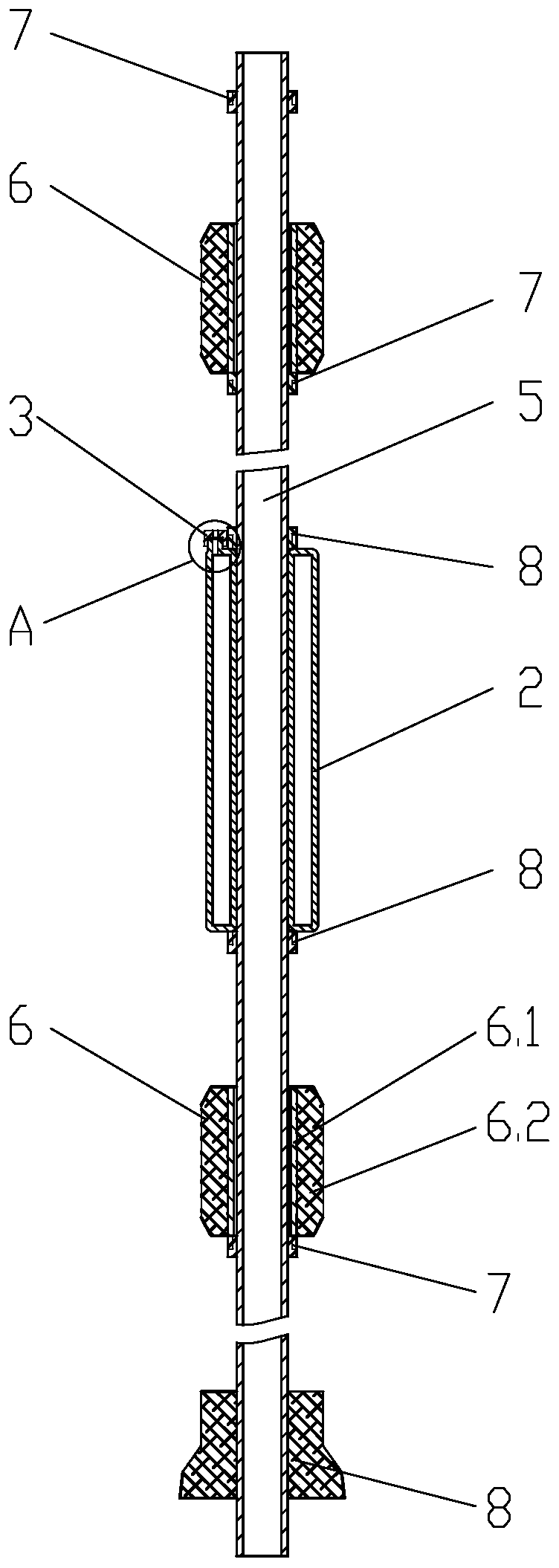

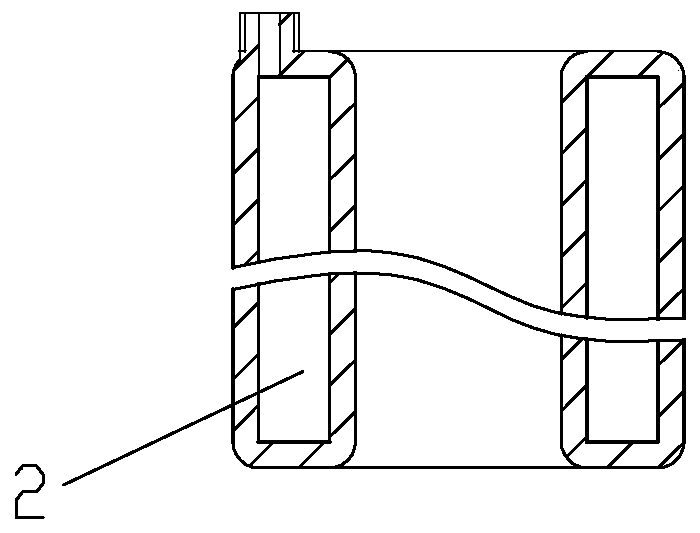

[0035] Example 1, see figure 1 , figure 2 , A quick-sealing device, comprising a draft tube 5, on the outer wall of the draft tube 5 are pierced with two sealing soft plugs 6 and a sealing agent cartridge 2 located between the two sealing soft plugs 6; The medicament cylinder 2 is fixedly connected with the guide tube 5, and the hole-sealing medicament cylinder 2 forms a weak part for the expansion of the swelling body; the sealing soft plug 6 is sealed and fixed in the intended sealing hole 1 through elastic deformation; the sealing soft plug 6 passes The clearance fit is sleeved on the guide tube 5, and the guide tube 5 is also fixedly connected with three first limiting elements 7, and the outer ends of the two sealing soft plugs 6 correspond to a first limiting element 7 located at the bottom of the hole The inner end of the soft sealing plug 6 corresponds to a first limiting element 7.

[0036] Wherein, the plugged medicament barrel 2 is fixed in axial position by two secon...

Embodiment 2

[0042] Example 2, see Image 6 , Figure 7 , The flow guide tube 5 is provided with two adjacent plugging drug barrels 2, and the flow guide tube 5 is formed with an exhaust hole 5a penetrating the hole wall of the flow guide tube 5, and the exhaust hole 5a is located in the sealing agent Between the cylinder 2 and the corresponding sealing soft plug 6, and close to the sealing soft plug 6; specifically, when used for downward or vertical downward drilling and sealing, the exhaust hole 5a is close to the orifice side and is located next to the sealing soft plug. The sealing soft plug 6 of the hole-sealing medicine cartridge 2; when used for upwardly obliquely or vertically upward drilling and sealing, the vent hole 5a is close to the bottom of the hole, and is located next to the sealing soft plug 6 of the sealing medicine cartridge 2. In addition, an inner liner 9 is provided in the guide tube 5 where the exhaust hole 5a is provided. An annular space 9a is formed between the in...

Embodiment 3

[0045] Example 3, see Figure 1 ~ Figure 6 , A rapid sealing method, implemented based on the sealing device of embodiment 1 or 2, and including the following steps:

[0046] In the first step, it is judged whether the first medicine is filled in the sealing medicine cartridge 2 in the quick sealing device, if so, the third step is executed, otherwise, the second step is executed;

[0047] The second step is to pour the first medicine into the plugged medicine cartridge 2;

[0048] The third step is to infuse the second medicament into the plugging medicament cylinder 2 and seal the plugging medicament cylinder 2;

[0049] The fourth step is to put the sealing device into the bore 1 to the set depth;

[0050] The fifth step, alternate forward and reverse rotation, and / or, push and pull the guide tube 5 back and forth to the set time;

[0051] The sixth step is to push the hole sealing device to the set depth of the drill hole 1, and use the hole plug 10 to seal the hole of the drill hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com