Two-way stretch soil mass reinforcement grating and manufacturing method thereof

A biaxial stretching and manufacturing method technology, applied in metal processing, soil protection, construction, etc., can solve the difficult adjustment and realization of stretching plastic geogrid processing technology, geogrid torsional rigidity and mesh stability low, does not meet the needs of high-strength two-way grilles, etc., to achieve significant economic and social benefits, improve torsional rigidity and mesh stability, and save engineering costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

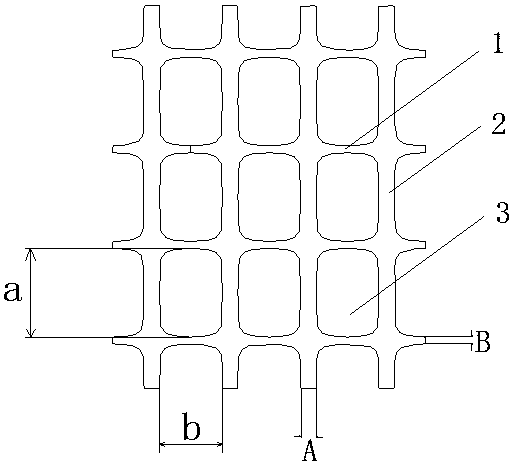

[0055] The process design parameters are: the longitudinal dimension a of the mesh 3 is 40 mm, the transverse dimension b of the mesh 3 is 20 mm, the ratio of the longitudinal tensile strength to the transverse tensile strength of the biaxially stretched plastic geogrid is 5:1, The thickness of the plastic extruded sheet is 4mm, and the size of the punch is selected as a1 and b1 are both 4mm punches. The arrangement of the punching holes is: the vertical spacing a2 of the punching holes is 12mm, and the horizontal spacing b2 of the punching holes is about (12-4)×(5:1) / (40:20)+4=24mm. The longitudinal stretch ratio is 40 / 4=10, and the transverse stretch ratio is 20 / 4=5. After pulling out the product, the longitudinal tensile strength is 75.2kN / m, the transverse tensile strength is 18.7kN / m, and the ratio of longitudinal and transverse tensile strength is about 4:1

[0056] Adjust the size of the punch, and adjust the longitudinal spacing a2 to 4+(12-4) / 18.7×(18.7-15)=5.6mm. A...

Embodiment 2

[0058] The process design parameters are: the longitudinal dimension a of the mesh 3 is 20mm, the transverse dimension b of the mesh 3 is 40mm, the ratio of the longitudinal tensile strength to the transverse tensile strength of the biaxially stretched plastic geogrid is 1:5, and the plastic The thickness of the extruded sheet is 8mm. The punch size is 4mm*8mm punch. The arrangement of the punching holes is: the horizontal spacing b2 of the punching holes is 13mm, and the vertical spacing a2 of the punching holes is (13-8)×(5:1) / (40:20)+4=16.5mm. Then the longitudinal stretch ratio is 20 / 4=5, and the transverse stretch ratio is 40 / 8=5. After pulling out the product, the longitudinal tensile strength is 12.2kN / m, the transverse tensile strength is 55.6kN / m, and the ratio of longitudinal and transverse tensile strength is about 1:4.56.

[0059] Adjust the size of the punch, and adjust the punching horizontal spacing b2 to 13-(13-8) / 12.2×(12.2-11.2)=12.6mm. After pulling out t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com