Environment-friendly drag reducing agent for fracturing, and preparation method thereof

A drag reducing agent and environmental protection technology, applied in the field of environmental protection drag reducing agent for fracturing, can solve the problems of high current danger, unsatisfactory surface interfacial tension and toxicity of drag reducing agent, and achieve ultra-low surface interfacial tension and high resistance reduction. efficiency, ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] An environmentally friendly drag reducer for fracturing, its composition and the mass percentage of each composition are:

[0032] Geminiquat 10%

[0033] Fatty alcohol polyoxyethylene ether 15%

[0034] Polyoxyethylene resin 0.5%

[0036] Nonionic Carboxylate Surfactant 3%

[0037] Cloud point depressant 1%

[0038] Anion and cation phase transfer agent 1%

[0039] The rest is water.

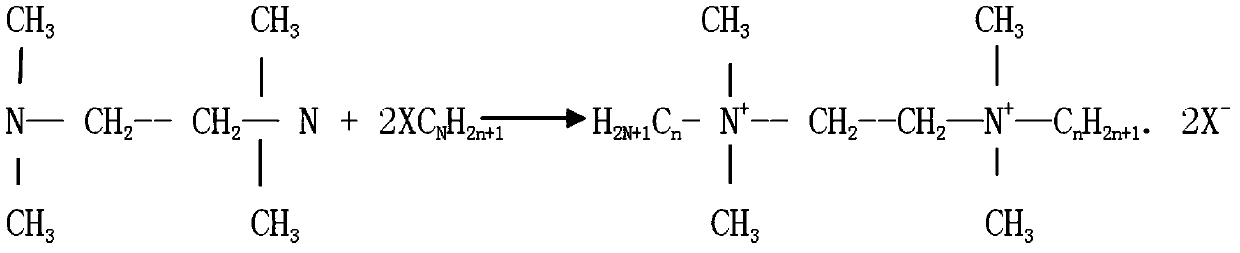

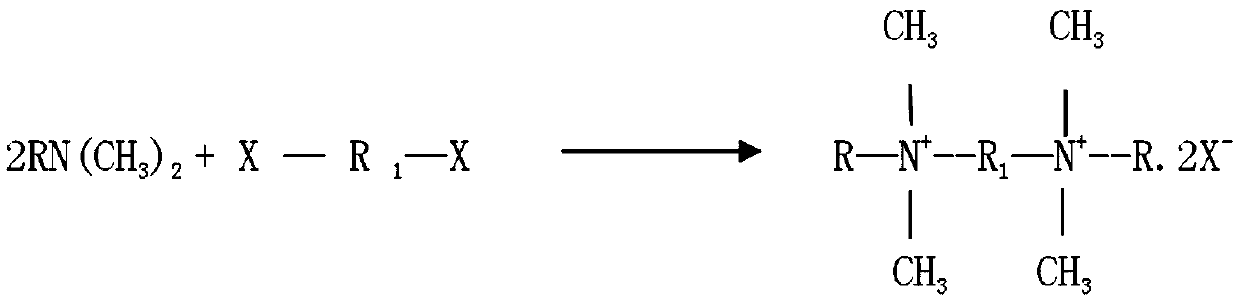

[0040] Among them, the gemini quaternary ammonium salt is Among them, R is a dodecyl group, R1 is a methyl group, R2 is a hexadecyl group, and X is a chlorine atom; fatty alcohol polyoxyethylene ether RO(CH 2 CH 2 O) n H molecular weight 2 million, alkylsulfonate RO(CH 2 CH 2 O) n SO 3 Na(R=C12 alkyl, n=2), the carboxylate surfactant is a non-ionic natural carboxylate surfactant, the cloud point depressant is erucamide propyl betaine, and the anion-cation phase transfer agent is ten Dialkyltrimethylbenzyl ammonium chloride.

[0041] The prepar...

Embodiment 2

[0044] An environmentally friendly drag reducer for fracturing, its composition and the mass percentage of each composition are:

[0045] Geminiquat 10%

[0046] Fatty alcohol polyoxyethylene ether 10%

[0047] Polyoxyethylene resin 0.5%

[0049] Nonionic Carboxylate Surfactant 3%

[0050] Cloud point depressant 1%

[0051] Anion and cation phase transfer agent 1%

[0052] The rest is water.

[0053] Among them, the gemini quaternary ammonium salt is Wherein, R is a dodecyl group, R1 is a methyl group, R2 is a hexadecyl group, and X is a chlorine atom;

[0054] The molecular weight of fatty alcohol polyoxyethylene ether is 2 million, alkylsulfonate RO(CH 2 CH 2 O) n SO 3 In Na, R=C12 alkyl, n=2, the cloud point depressant is cocamidopropyl sulfobetaine, and the anion-cation phase transfer agent is dodecyltrimethylbenzyl ammonium chloride.

[0055]The preparation method of environmentally friendly drag reducer for fracturing: first add ...

Embodiment 3

[0058] An environmentally friendly drag reducer for fracturing, its composition and the mass percentage of each composition are:

[0059] Geminiquat 10%

[0060] Fatty alcohol polyoxyethylene ether 15%

[0061] Polyoxyethylene resin 0.5%

[0062] Sulfonate 15%

[0063] Nonionic Carboxylate Surfactant 3%

[0064] Cloud point depressant 1%

[0065] Anion and cation phase transfer agent 1%

[0066] The rest is water.

[0067] Among them, the gemini quaternary ammonium salt is Wherein, R is a dodecyl group, R1 is a methyl group, R2 is a hexadecyl group, and X is a chlorine atom;

[0068] The molecular weight of fatty alcohol polyoxyethylene ether is 4 million, and the sulfonate RO(CH 2 CH 2 O) n SO 3 Na, wherein R=C12 alkyl, n=2, the cloud point depressant is erucamide propyl sulfobetaine, and the anion-cation phase transfer agent is dodecyltrimethylbenzyl ammonium chloride.

[0069] The preparation method of environmentally friendly drag reducer for fracturing: first...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com