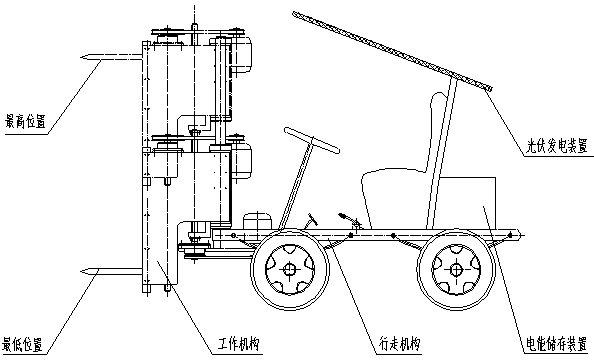

Agricultural light-weight electric straw bale forking and loading vehicle

A light, electric technology, applied in the direction of lifting devices, etc., can solve the problems of heavy weight, unsuitable for handling and loading scattered straw bales in the field, and lack of lightness and suitableness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

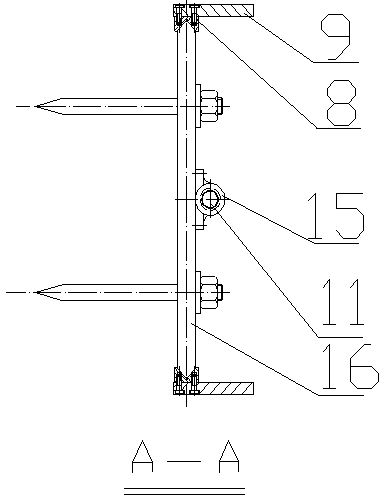

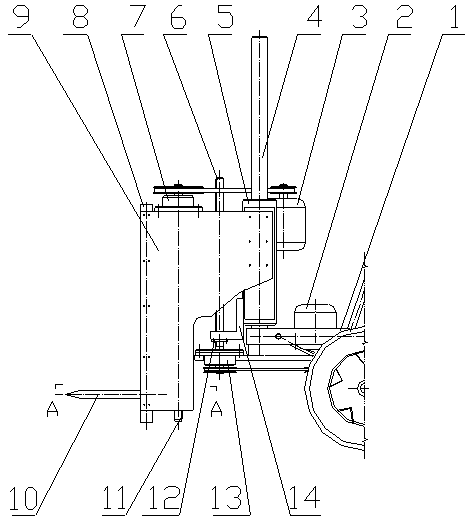

[0010] Below in conjunction with accompanying drawing, the invention is described in further detail. The invention is divided into three parts, one is the main lifting part; the other is the auxiliary lifting part; the third is the photovoltaic power generation energy storage device. The working process of the main lifting part: the main motor 2 is fixed on the mounting frame 1. When the main motor 2 is started, the main screw rod 6 is driven to rotate through the main transmission assembly 13. At this time, the main screw nut 12 and the bending plate 14 are matched with it. etc., drive the side plate 9 and the pin 10 to start moving up and down, realizing the insertion and lifting functions of the bale; auxiliary lifting parts: all parts of the auxiliary lifting parts are respectively connected with the sleeves in the main lifting parts The cylinder 5 and the side plate 9 are fixedly connected. When the auxiliary motor 2 is started, the auxiliary screw rod 11 is driven to rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com