Vertical substrate (glass) carrying device

A handling device and glass technology, which is applied in the direction of transportation and packaging, conveyor objects, furnaces, etc., can solve the problems of unreasonable design of solar panel production capacity, increased floor space, and high cost, so as to facilitate operation and maintenance of cassettes and reduce take-out release time and reduce the effect of the vacuum device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

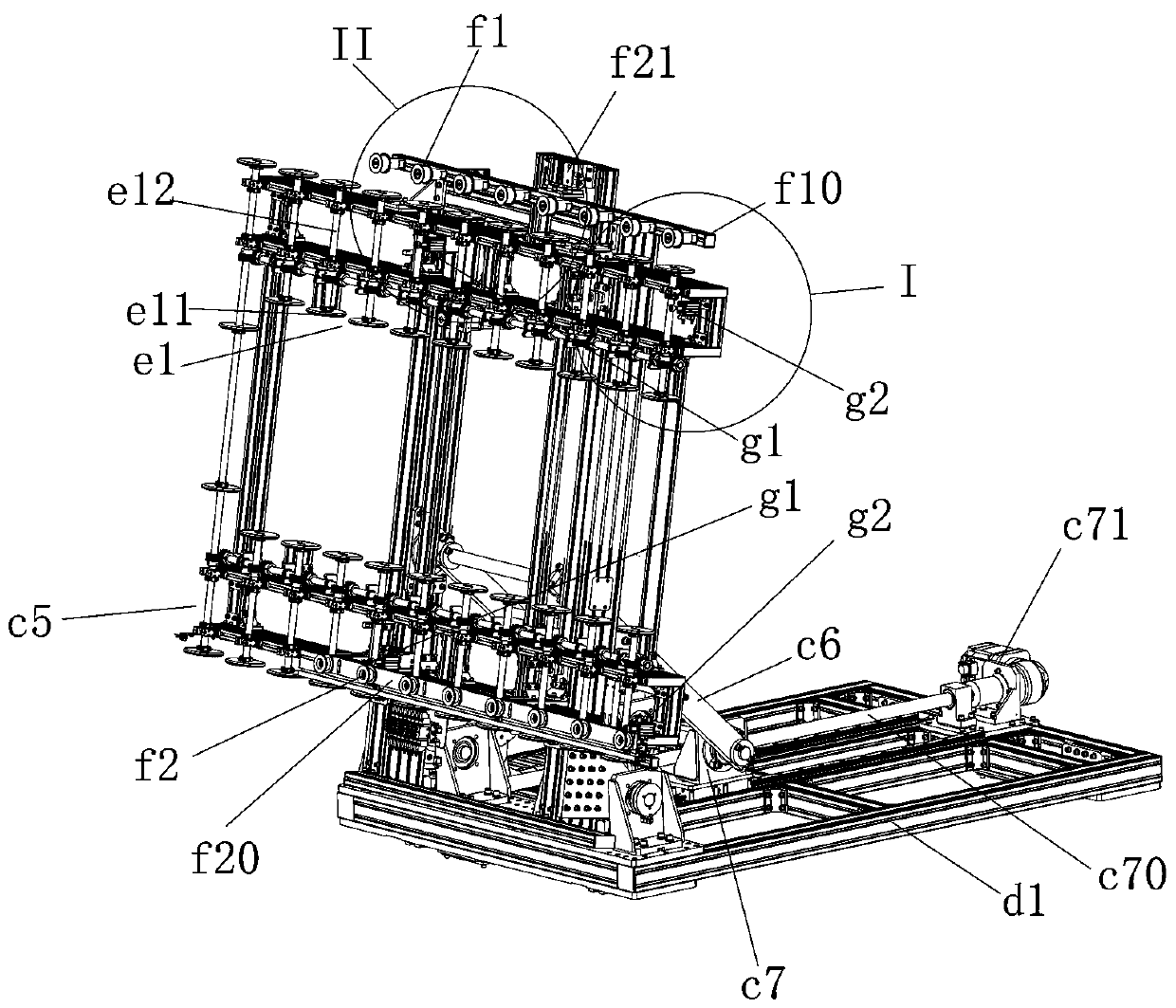

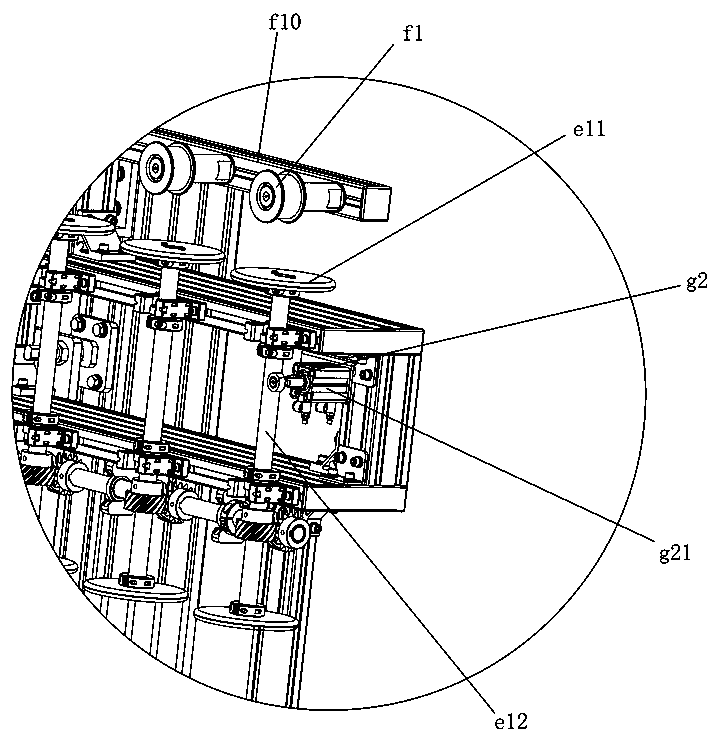

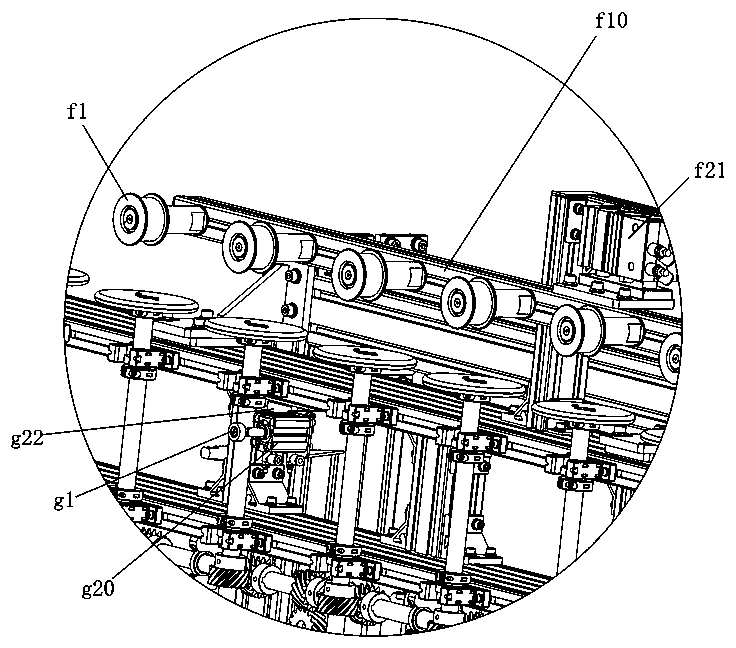

[0016] Example 1, such as Figure 1-9 As shown, a vertical substrate (glass) conveying device includes a vertical glass conveying mechanism m and a glass clamping device n matched with the vertical glass conveying mechanism m and arranged on the vertical glass conveying mechanism, the vertical glass conveying The mechanism includes an overturning frame c5 that can be turned over from horizontal to vertical. The overturning frame c5 is installed on a bottom conveying frame d1 that can move in the left and right directions. The bottom conveying frame d1 is installed on the conveying platform d. A left-right correction mechanism d2 and a front-back correction mechanism d3 for clamping the glass plate are installed on the frame c5, and a storage mechanism s for storing the glass plate is provided at the outlet end of the vertical glass transfer mechanism. The conveying platform d can adopt existing structures such as platforms with conveying guide rails, and the bottom conveying f...

Embodiment 2

[0036] Example 2, such as Figure 10-18 As shown, a vertical glass storage cassette system that can be applied to Embodiment 1 includes a cassette a. The cassette a has a three-dimensional support frame a1, and a cubic or cuboid frame structure can be selected. The three-dimensional support frame a1 consists of A number of leaning frames b1 are arranged side by side at intervals from left to right, and a leaning device is provided on the leaning frame b1 for the glass plate a0 to lean against. The plane b20 is inclined to the horizontal plane. Further preferably, leaning on the support surface b20 is parallel to the front-to-back direction. Here, the front-to-back direction can be understood as the direction perpendicular to the three-dimensional support frame a1, which is arranged left and right. The front-to-back direction is also the direction in which the glass plate a0 enters and exits. It is convenient to transport the glass plate a0 in this direction. It is also reliab...

Embodiment 3

[0051] Example 3, such as Figure 19-23 As shown, a cassette door curtain that can be applied to the cassette in Embodiment 2 is provided. The door curtain is designed at the position of the main body of the door curtain on the front frame of the three-dimensional support frame a1 of the cassette a. The idea of its design is: the door curtain The main body and the power device are two independent bodies. In order to achieve the function of automatically opening and closing the door curtain, the magnetic force conduction between the two is required to realize the lifting of the door curtain, so that the door curtain of the cassette can be turned around without the power device, so that the card The flexibility of the cassette is greatly improved, which not only improves the efficiency in the glass production process, but also greatly helps in the production of high-quality glass.

[0052] Specifically, it is a cassette door curtain with a magnetic control switch, including a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com