Intelligent servo screw locking equipment for clothes hanger

A technology for locking screws and drying racks, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of high locking and payment costs, low locking and payment efficiency, and increased enterprise costs, saving pick-and-place time and convenient data. Manage and enhance the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

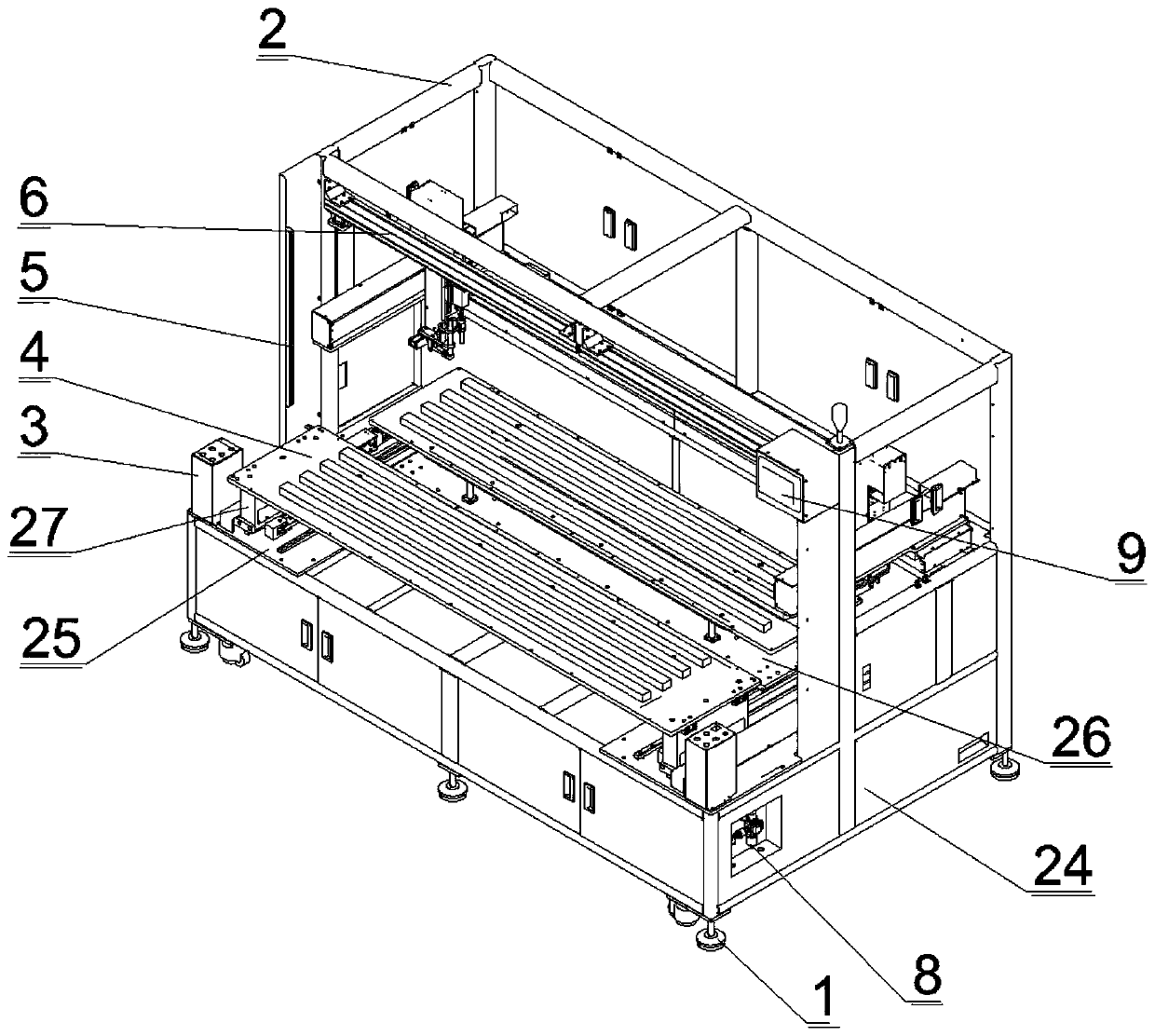

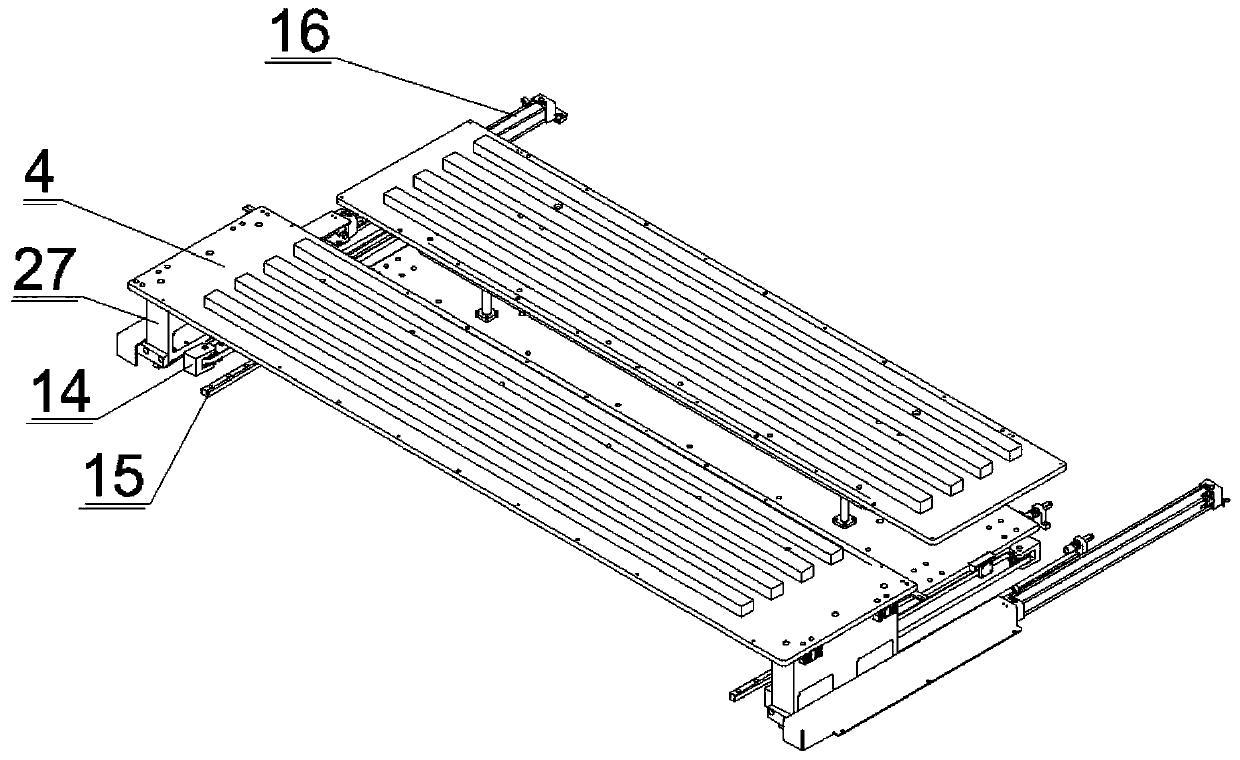

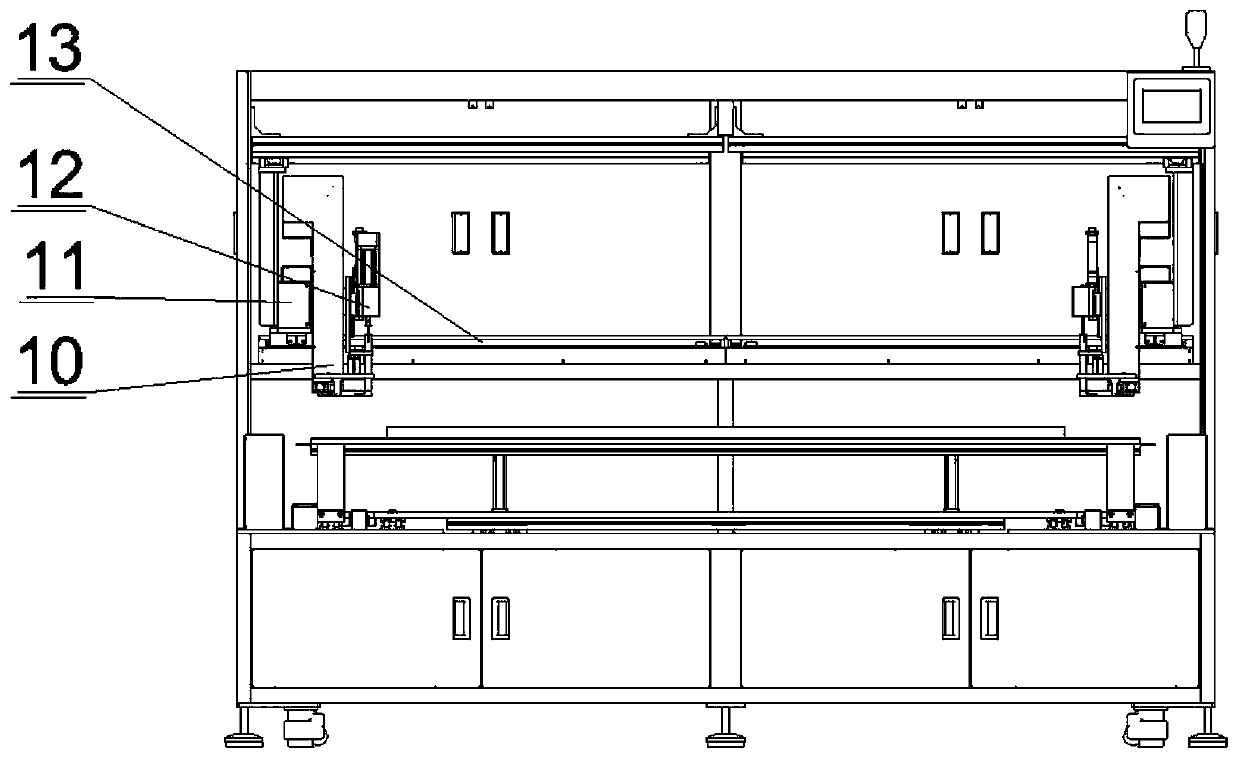

[0030] Such as Figure 1-4 As shown, an intelligent servo locking screw device for drying racks includes an equipment rack 2, an equipment cabinet 24, and a servo locking mechanism 12. The bottom of the equipment cabinet 24 is provided with multiple sets of casters 1, and the equipment cabinet 24 is equipped with screw feeders. Machine and electric control box, one side of the equipment cabinet 24 is also provided with an air source processing element 8, two equipment base plates 25 are respectively provided on both sides of the upper end of the equipment cabinet 24, and two operation panels are respectively provided on both sides of the front ends of the two equipment base plates 25 3. Two jig switching cylinders 16 are respectively provided on the inside of the two operation panels 3, and two jig switching synchronous wheels 14 and two jig slides are respectively provided on the side of the two jig switching cylinders 16 away from the operation panel 3. rail 15, a jig switch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com