Clearing and blowing device used for cigarette conveyor

A belt conveyor, cleaning and blowing technology, applied in the direction of cleaning devices, transportation and packaging, conveyor objects, etc., can solve the problems that the attachments affect the normal use of the belt conveyor, the labor intensity of the workers is high, and the cleaning is difficult, so as to improve the cleaning and blowing Efficiency, reduced labor load, and efficient cleaning effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below.

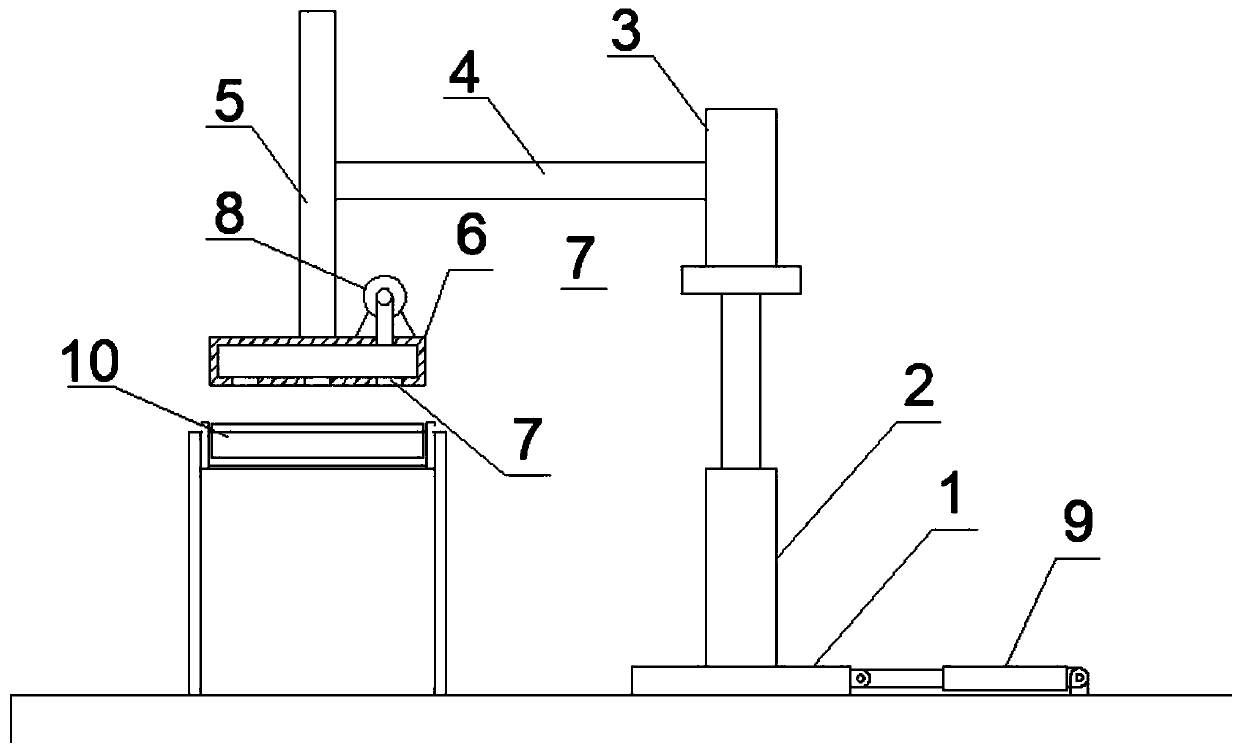

[0013] Such as figure 1 As shown, a cleaning and blowing device for a cigarette belt conveyor includes a support base 1 and a vertically arranged lifting hydraulic cylinder 2;

[0014] The cylinder base of the lifting hydraulic cylinder 2 is fixedly connected with the upper center of the support base 1, and the end of the piston rod is fixedly connected with a vertical beam 3;

[0015] The upper left side of the vertical beam 3 is fixedly connected with a crossbeam 4, and the left end of the crossbeam 4 is fixedly connected with a vertical beam 5; the lower end of the vertical beam 5 is fixedly connected with a bellows 6; A plurality of blowing holes 7; the top of the bellows 6 is fixedly connected with a fan 8, and the air outlet of the fan 8 is connected with the inner cavity of the bellows 6 through a pipeline.

[0016] In order to push the bellows to the top of the belt conveyor 10 to be cleaned, and also to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com