An automatic packaging system for pvc adhesive cloth foam tube

A technology of automatic packaging and cotton tubes, which is applied in the direction of packaging, transportation and packaging, packaging/bundling items, etc., and can solve problems such as low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

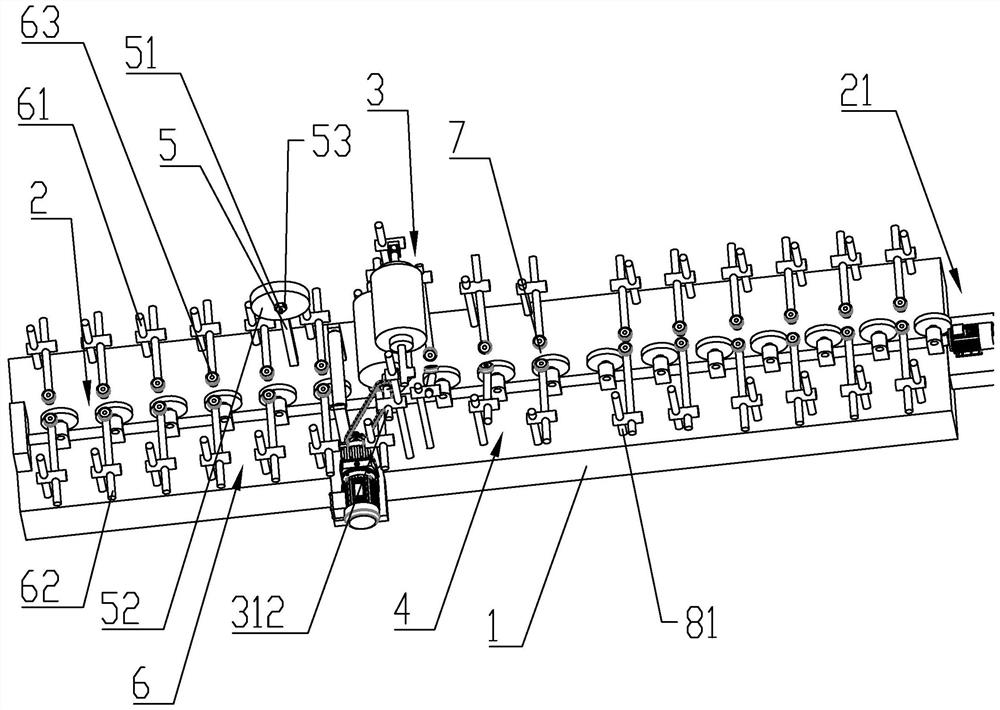

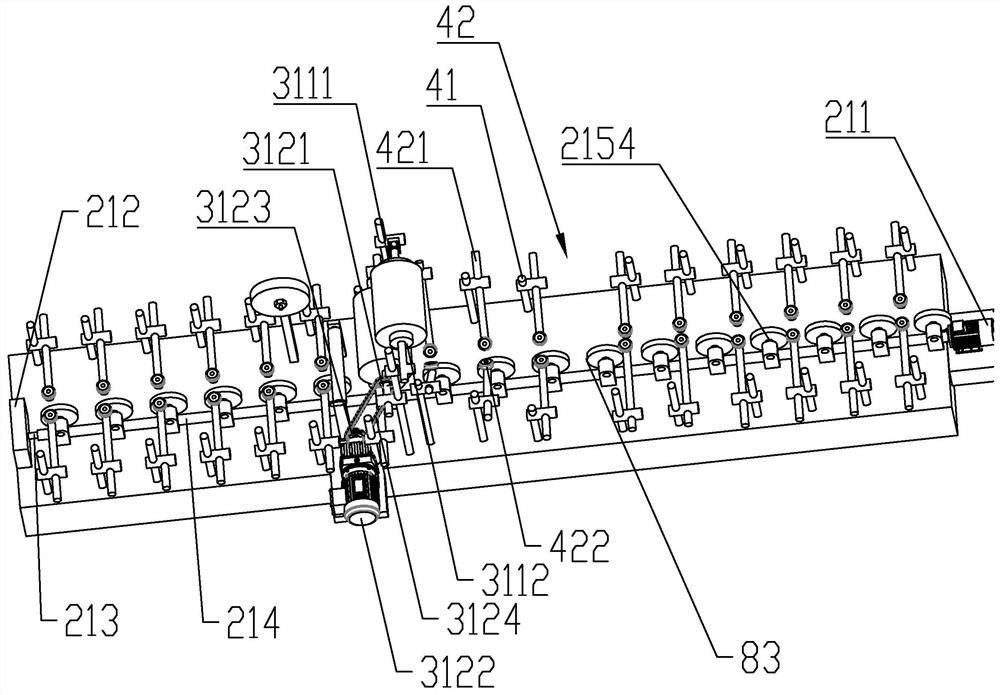

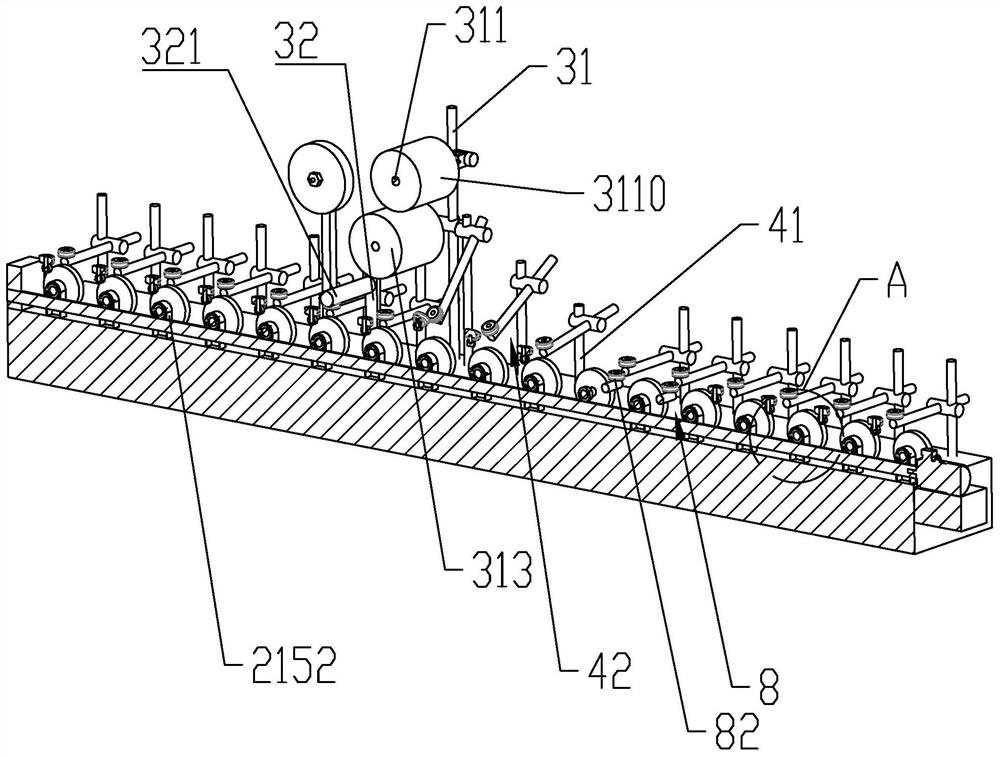

[0040] refer to figure 1 and figure 2 , an automatic packaging system for PVC tape foam tubes disclosed by the invention, including a platform 1 . A conveying mechanism 2 is arranged on the platform 1, and the conveying mechanism 2 transports the foam tube from one end of the platform 1 to the other end of the platform 1. To achieve the purpose of automatic feeding. The conveying mechanism 2 includes a power assembly 21 and a plurality of first rotating wheels 22 , and the power assembly 21 drives the first rotating wheels 22 to rotate. The foam tube is placed on the first rotating wheel 22. Since the material of the foam tube and the first rotating wheel 22 have relatively high friction, the foam tube can be driven to move when the first rotating wheel 22 rotates.

[0041] refer to figure 2 and Figure 4 , the power assembly 21 includes a first motor 211 , a fixed block 212 , a first fixed rod 213 , a worm 214 and several rotating assemblies 215 . The first motor 211 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com