Multifunctional automatic counting and packing machine for hang tags

A multi-functional, hang tag technology, applied in the directions of automatic packaging control, packaging, packaging protection, etc., can solve the problems of packaging and discharging of tag tails, stacking multiple sheets together, etc., to achieve automatic counting and packaging, improve the accuracy of counting data, and improve quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

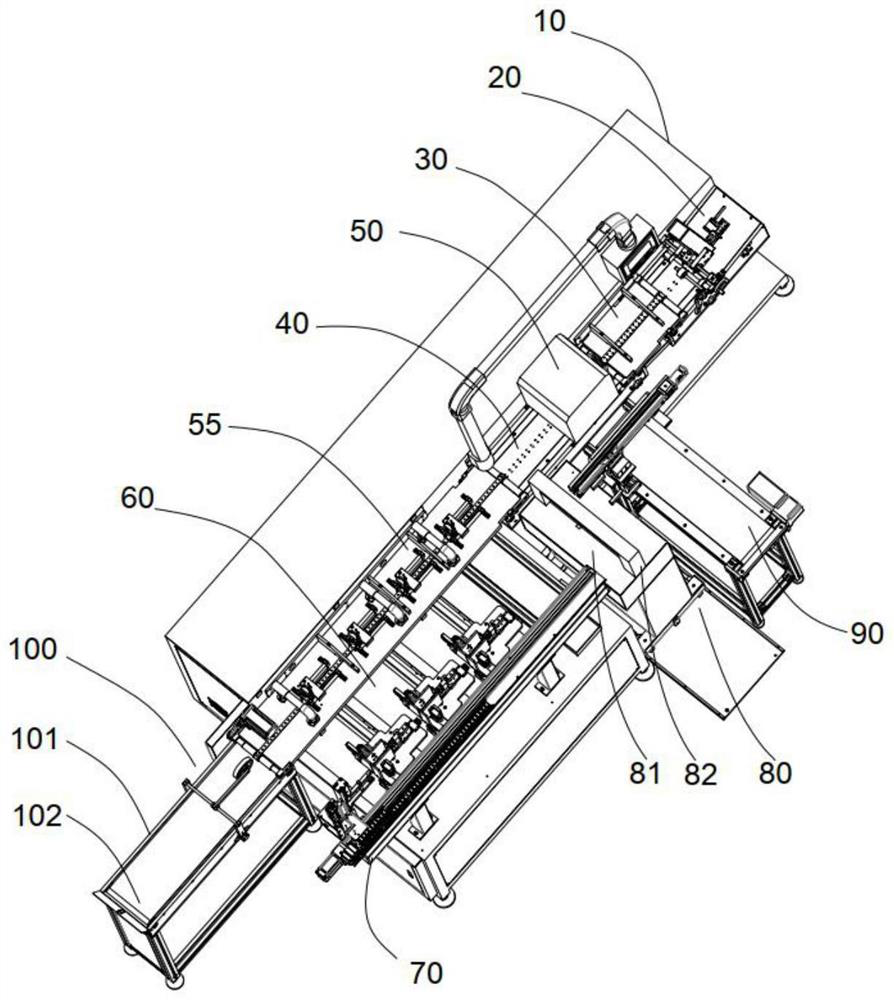

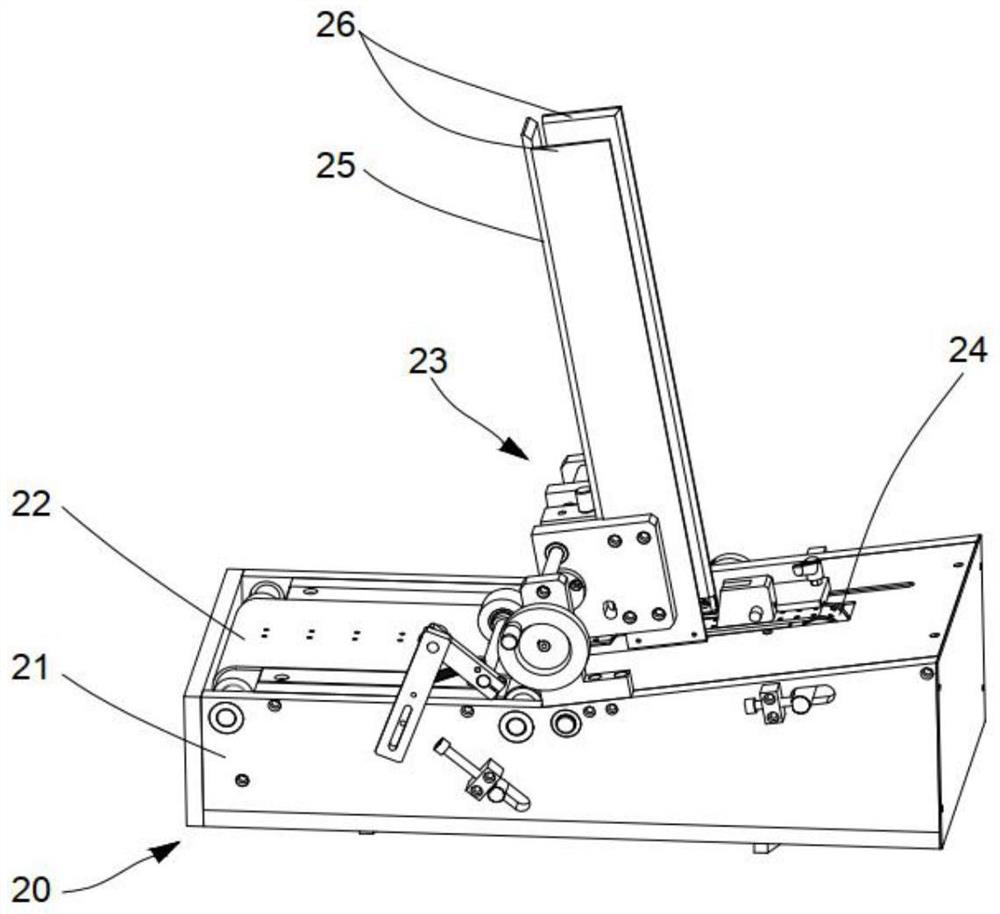

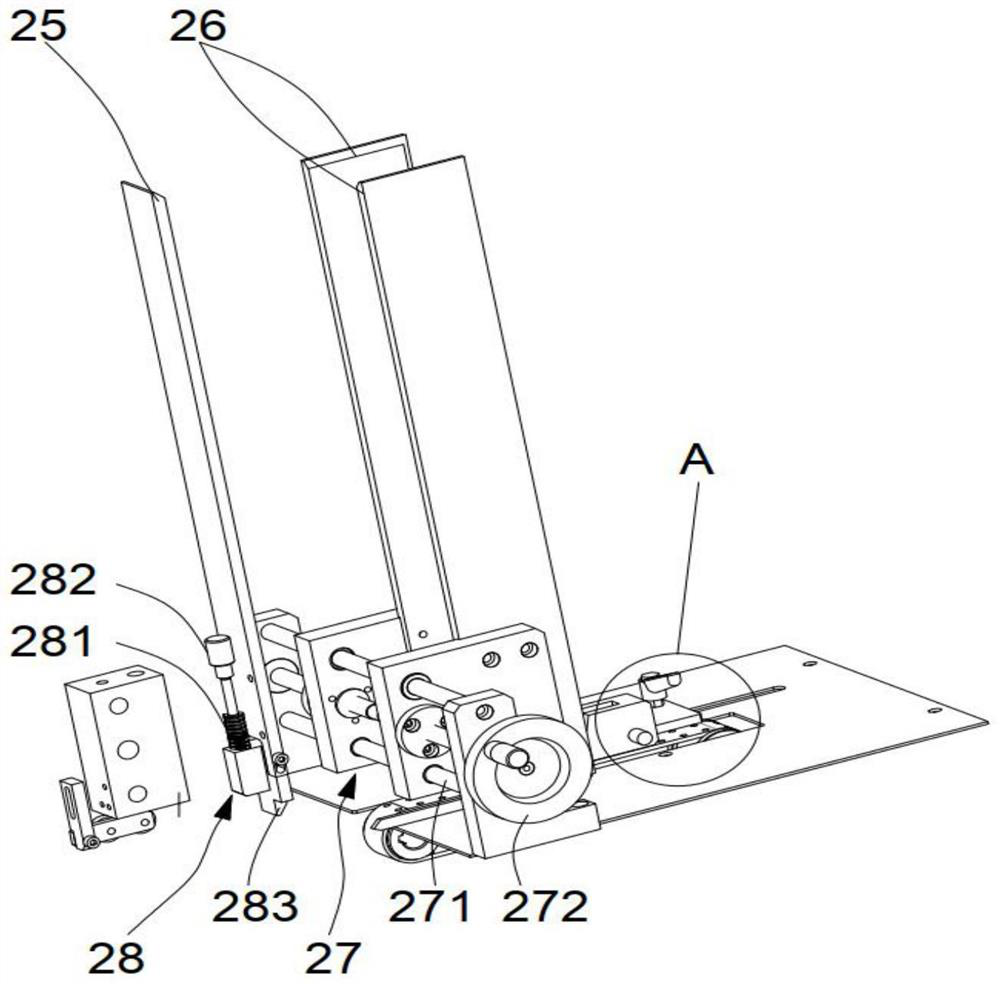

[0038] see Figure 1 to Figure 17, the present embodiment provides a multi-functional tag automatic counting packing machine, including a frame 10, and also includes a transport device 40 installed on one side of the frame 10, and a guide device 55 installed on one side of the transport device 40, The feeding device 20 installed on one side of the transport device 40 ; meanwhile, an anti-double sheet device 30 is also installed between the transport device 40 and the feeding device 20 . The transportation device 40 includes a transportation platform 41 and a transportation belt 42 installed on the transportation platform 41 , and a quality inspection device 50 is installed above the transportation belt 42 . The feeding device 20 is used to place batches of hang tags to be detected, and then the hang tags are transported to the anti-double device 30, which is used to prevent multiple hang tags from overlapping together, and then the single hang tags are transported to The tran...

Embodiment 2

[0093] Please refer to figure 1 The embodiment of the present invention differs from Embodiment 1 in that an unpacked receiving device 100 is also provided on one side of the unpacking device 60, and the unpacked receiving device 100 includes an unpacked receiving frame 101 and is installed on an unpacked receiving device. The material receiving belt 102 is not packaged on the material frame 101, and the other end of the second vacuum conveyor belt 551 is installed above an end of the material receiving belt 102 without packaging.

[0094] In one embodiment, the first guiding mechanism 57, the second guiding mechanism 58, and the third guiding mechanism 59 installed on the guiding platform 550 are not in working condition, and the qualified hang tags conveyed on the second vacuum conveyor belt 551 can be Directly be transported to one end of the material receiving belt 102 without packaging, and finally directly receive the material.

Embodiment 3

[0096] The difference between this embodiment of the present invention and Embodiment 1 is that the first counting part 6214 can be installed on the first guide mechanism 57, and this installation relationship does not affect the above-mentioned first counting part 6214 for the first counting part 6214. The hanging tags collected by a material receiving frame 630 carry out the effect of pre-stored counting and mantissa counting; the second counting part 6224 can be installed on the second guide mechanism 58, and this installation relationship does not affect the above-mentioned second counting part 6224. It is used to collect and count the hang tags collected by the second receiving frame 650; the third counting member 6234 can be installed on the third guiding mechanism 59, and this installation relationship does not affect the above-mentioned use for the third receiving. Block 670 collects hang tags to effect the collection count.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com