Antibacterial moisture-absorbing heating composite fabric and preparation method thereof

A technology of composite fabrics, moisture absorption and heat generation, applied in the field of clothing fabrics, can solve the problems of inability to meet the antibacterial properties of fabrics, the antibacterial effect is not durable, and the antibacterial effect is reduced, and achieves the effect of promoting the human microenvironment, good thermal insulation effect, and strong practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

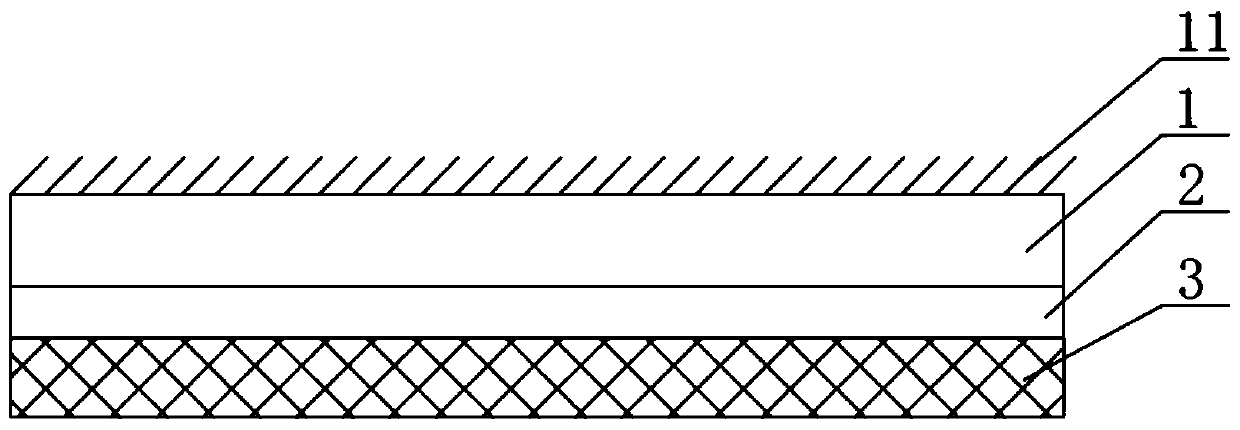

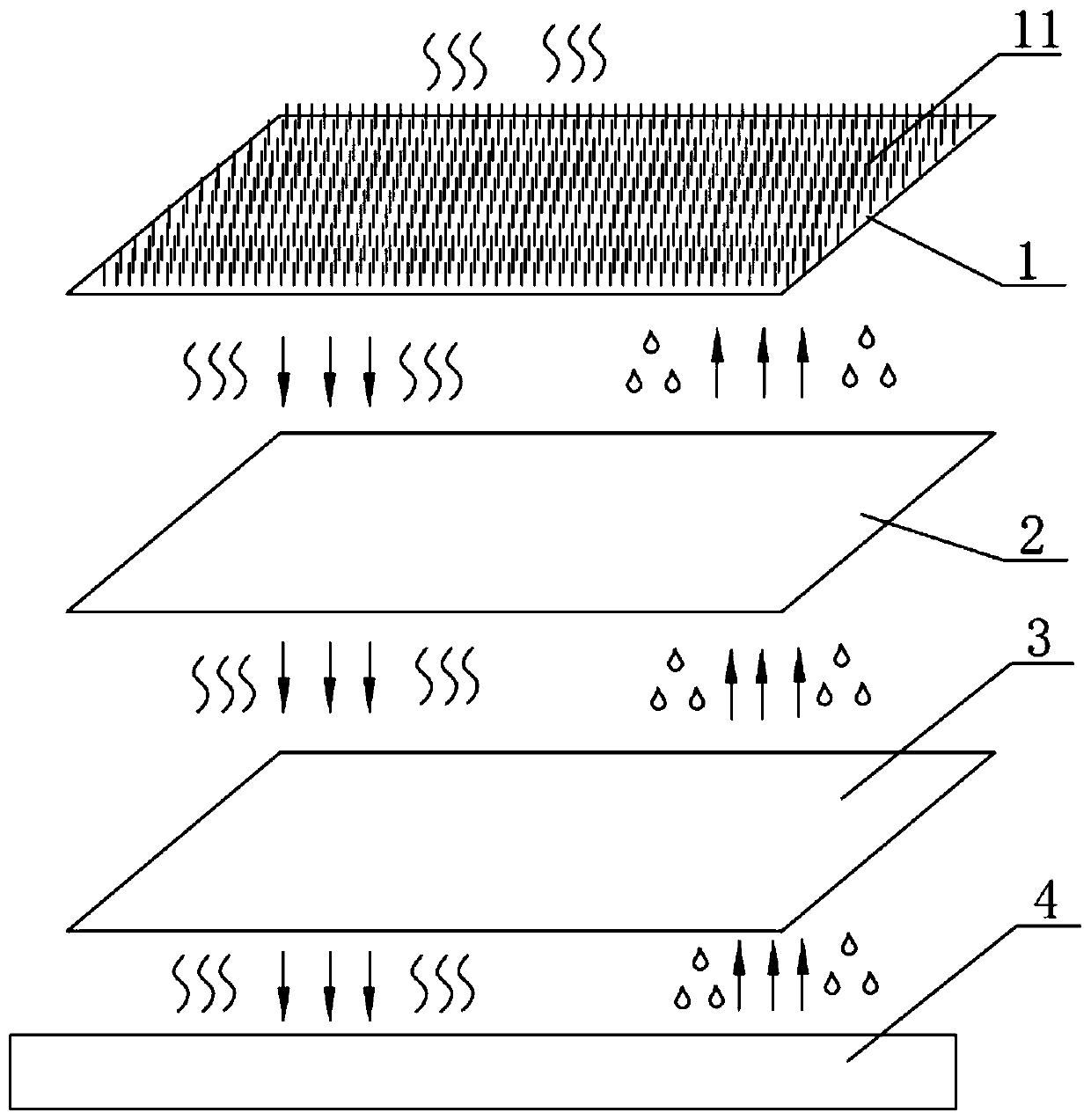

[0052] Such as figure 1 As shown, an antibacterial, moisture-absorbing and heat-generating composite fabric of this embodiment has a three-layer integrated structure. Moisture-absorbing and heat-generating polar fleece fabric, and the inner fabric 3 is an antibacterial mesh knitted fabric.

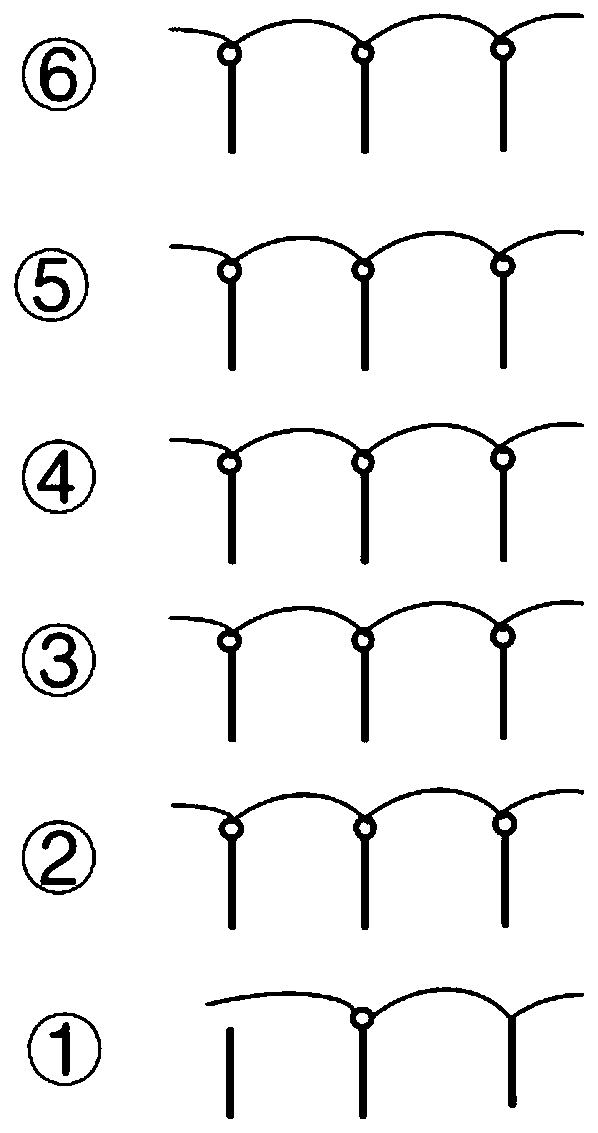

[0053] The polar fleece fabric is a single-sided towel structure, including a ground structure made of polyester low-stretch yarn, and a fluff layer 11 made of blended yarn is woven on the ground structure. The blended yarn is prepared from ultra-fine polyester and heat-generating viscose; heat generation The viscose is a moisture-absorbing and heating fiber; the thickness of the fluff layer 11 is 0.5mm-1mm, and the fluff layer 11 can retain more still air, so that the warming effect of the fabric is better.

[0054] The moisture-absorbing and heating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com