Fire fighting cabinet

A technology for fire cabinets and fire extinguishers, applied in fire rescue and other directions, can solve the problems of inability to spray fire extinguishing agent, inability to roll up water pipes, and difficulty in taking and storing fire extinguishers, achieving the effect of convenient storage and utilization of storage space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

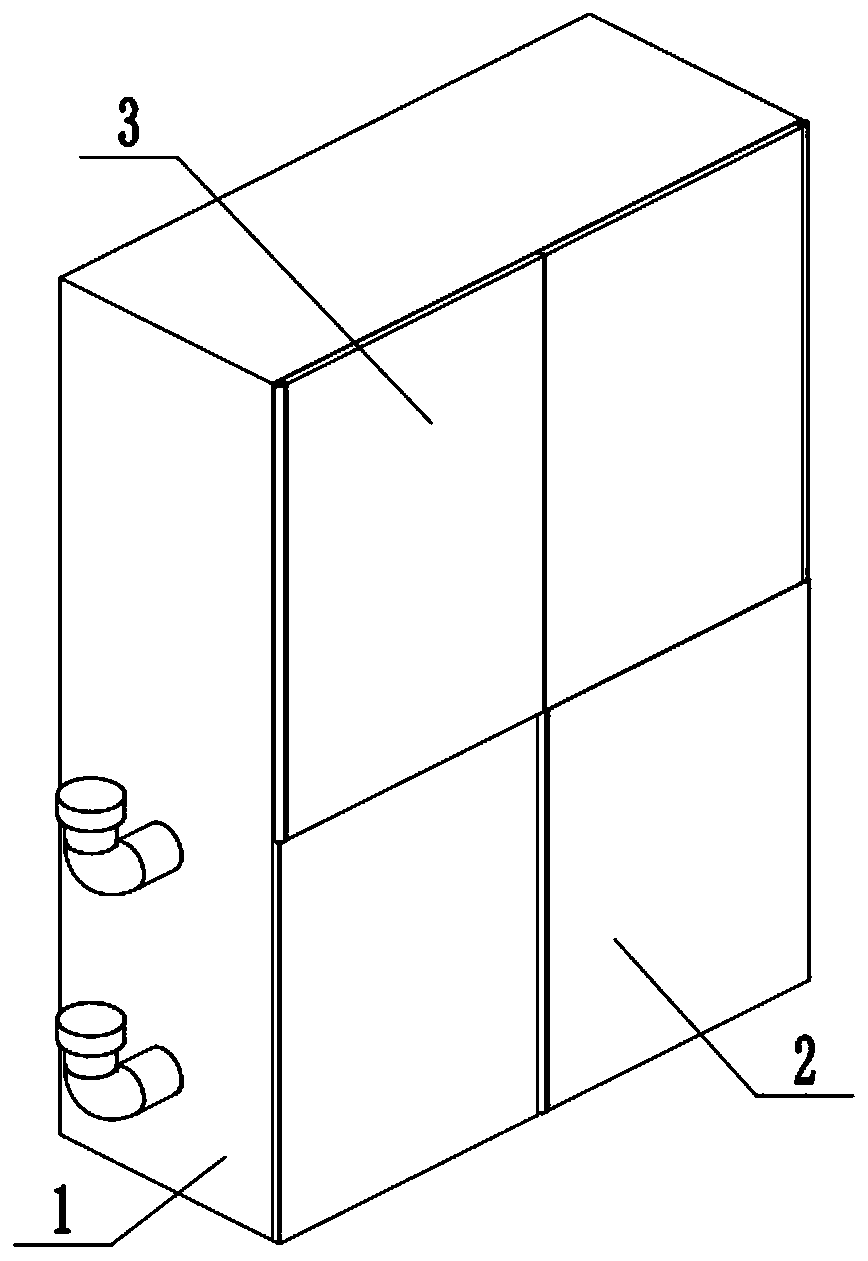

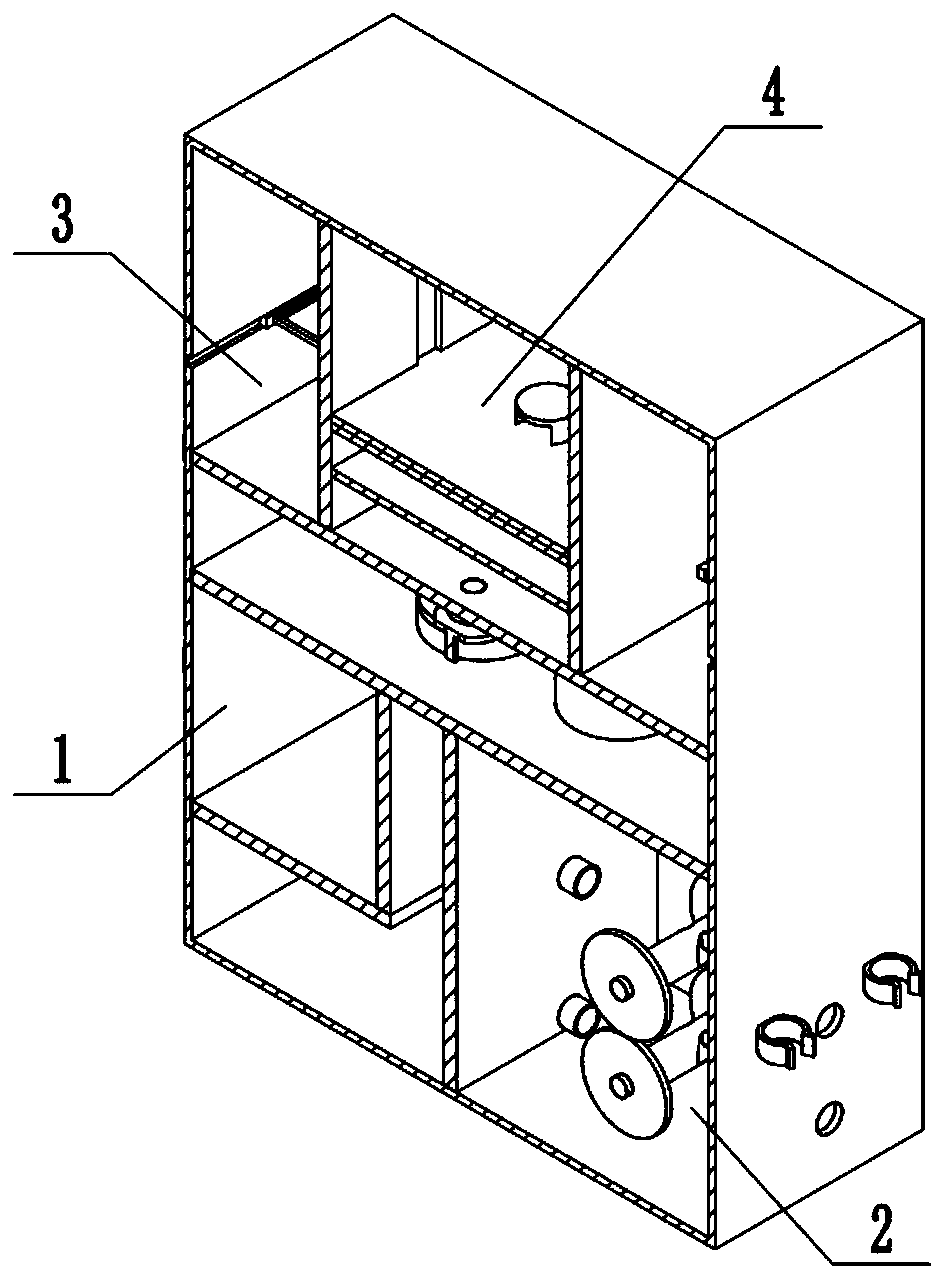

[0033] Combine below Figure 1-18 In this embodiment, a fire fighting cabinet includes a liquid storage assembly 1, a coiled tube assembly 2, a fire extinguisher clamping assembly 3, and a storage assembly 4. It is characterized in that: the coiled tube assembly 2 and the liquid storage The assembly 1 is connected, the fire extinguisher clamping assembly 3 is connected with the liquid storage assembly 1, and the storage assembly 4 is connected with the liquid storage assembly 1.

specific Embodiment approach 2

[0035] Combine below Figure 1-18This embodiment, this embodiment will further explain the first embodiment, the liquid storage assembly 1 includes a fire cabinet 1-1, a horizontal frame 1-2, a motor I1-3, a motor I shaft 1-4, and a sprocket I1 -5, chain Ⅰ1-6, sprocket Ⅱ1-7, fan housing 1-8, fan blade shaft 1-9, fan blade 1-10, air inlet 1-11, switch lever chute 1-12, switch lever 1 -13, switching shaft 1-14, windshield 1-15, box door 1-16, box Ⅰ side plate 1-17, box Ⅰ bottom plate 1-18, box Ⅱ side plate 1-19, water pipe Ⅰ 1-20, Water pipe Ⅱ1-21, curved groove 1-22, water inlet pipe 1-23, end cover 1-24, box Ⅰ1-25 and box Ⅱ1-26, horizontal frame 1-2 is connected with fire cabinet 1-1, motor Ⅰ1- 3 is connected with the horizontal frame 1-2, the motor I1-3 is connected with the motor I shaft 1-4, the motor I shaft 1-4 is connected with the sprocket I1-5, the sprocket I1-5, the chain I1-6, The sprocket Ⅱ1-7 is connected by a sprocket chain, the sprocket Ⅱ1-7 is connected with t...

specific Embodiment approach 3

[0037] Combine below Figure 1-18 This embodiment, this embodiment will further explain the first embodiment, the coiled tube assembly 2 includes the sliding door I2-1, the motor II bracket 2-2, the motor II2-3, the motor II shaft 2-4, and the gear I2 -5, friction block 2-6, gear II 2-7, rotary rod 2-8, gear II shaft 2-9, gear III 2-10, reel shaft 2-11, friction groove 2-12, reel 2-13 , pipe hole Ⅰ2-14, faucet clip 2-15 and pipe hole Ⅱ2-16, the sliding door Ⅰ2-1 is hinged with the box Ⅱ side panel 1-19, the motor Ⅱ bracket 2-2 is connected with the fire cabinet 1-1 rear panel , motor II 2-3 is connected with motor II bracket 2-2, motor II 2-3 is connected with motor II shaft 2-4, motor II shaft 2-4 is rotationally connected with fire cabinet 1-1 rear plate, motor II shaft 2 The two friction grooves 2-12 on -4 are in contact with the two friction blocks 2-6 respectively, and the two friction blocks 2-6 are respectively connected with the gear I 2-5 and the rotary rod 2-8, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com