Electromagnetic shielding film, circuit board, and preparation method of electromagnetic shielding film

An electromagnetic shielding film, printed circuit board technology, applied in the field of electronics, can solve the problems of grounding failure, inability to interfere with charge export, inability to achieve shielding function, etc., to achieve the effect of shielding function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

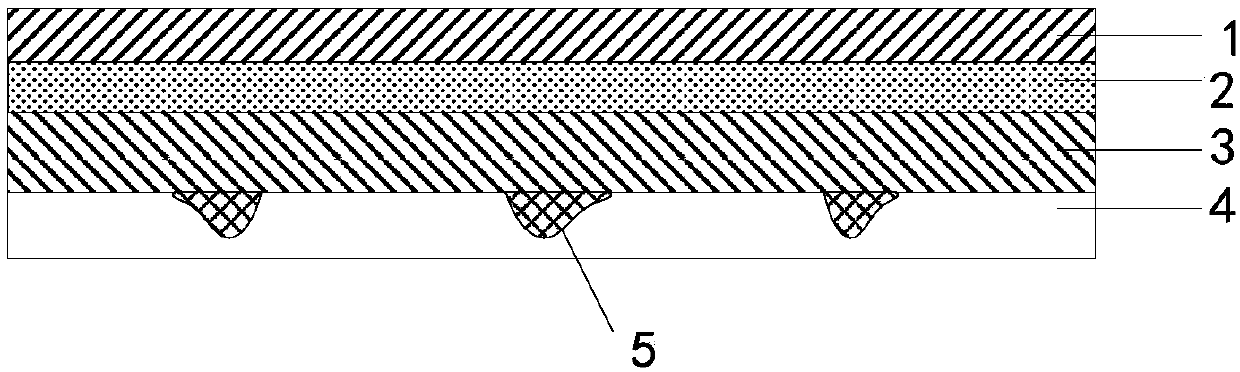

[0072] See figure 1 , the embodiment of the present invention provides an electromagnetic shielding film, which includes a first shielding layer 1, an adhesive layer 2, a second shielding layer 3 and an adhesive film layer 4 stacked in sequence; the second shielding layer 3 is close to the Conductive protrusions 5 are provided on one side of the adhesive film layer 4 . Wherein, the material of the conductive protrusion 5 may be pure metal, alloy or conductive glue with good electrical conductivity, which is not specifically limited here.

[0073] In this embodiment, by providing a conductive protrusion 5 on the side of the second shielding layer 3 close to the adhesive film layer 4, the conductive protrusion 5 ensures that the second shielding layer 5 is The shielding layer 3 can smoothly pierce through the adhesive film layer 4 and contact the ground layer of the circuit board 8, and then ensure that the interference charges are normally exported under the cooperation of the...

Embodiment 2

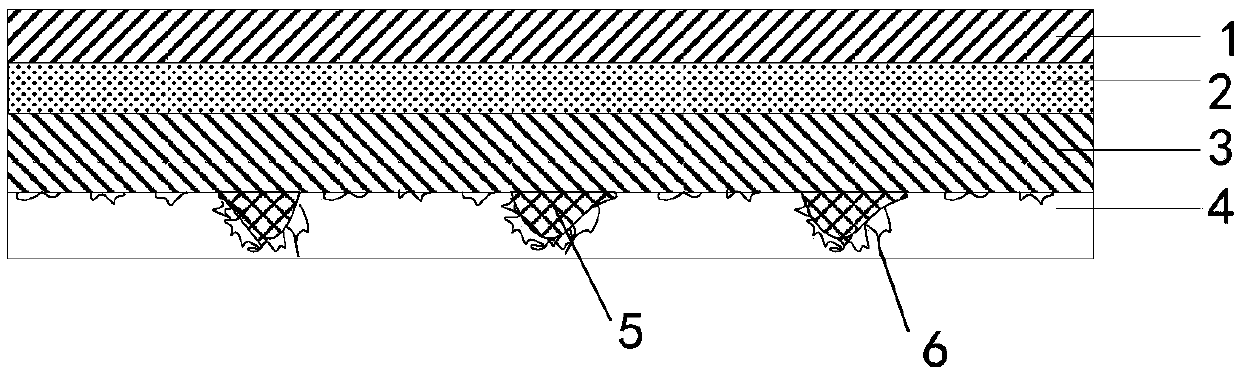

[0103] see Figure 4 , the embodiment of the present invention provides another electromagnetic shielding film, which includes a first shielding layer 1, an adhesive layer 2, a second shielding layer 3, a third shielding layer 7 and an adhesive film layer 4; the first shielding layer 1. The adhesive layer 2 and the second shielding layer 3 are stacked in sequence; the second shielding layer 3 is provided with conductive protrusions 5 on the side away from the adhesive layer 2; the third The shielding layer 7 is covered on the one side of the second shielding layer 3, and the position of the third shielding layer 7 covering the conductive protrusion 5 forms a raised portion 70 (the raised portion 70 is in contact with The relationship between the conductive bumps 5 can be one-to-one correspondence, one-to-many correspondence, or many-to-one correspondence, etc. When the relationship between the raised portion 70 and the conductive bumps 5 is a one-to-one correspondence, the rai...

Embodiment 3

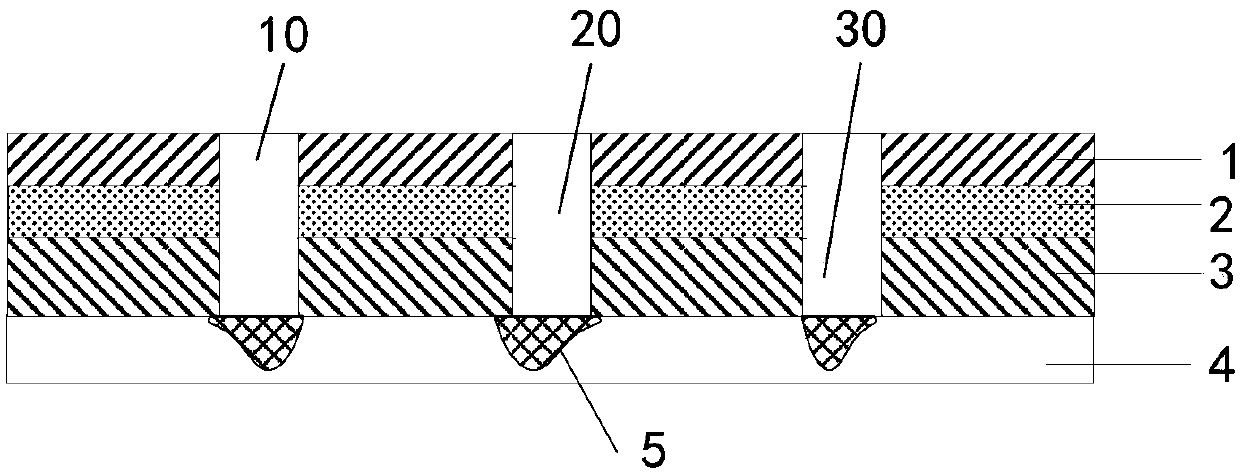

[0116] see Figure 9 and Figure 10 , the embodiment of the present invention provides a circuit board, including a printed circuit board 8 .

[0117] see Figure 9 , the circuit board also includes the electromagnetic shielding film of any solution in the first embodiment; the electromagnetic shielding film is pressed on the printed circuit board 8, and the adhesive film layer 4 is close to the printed circuit board , specifically, the second shielding layer 3 may be in direct contact with the printed circuit board or there is an interval between the two; the conductive protrusion 5 pierces the adhesive film layer 4 and extends to the printed circuit board 8 strata.

[0118] or, see Figure 10, the circuit board also includes the electromagnetic shielding film of any solution in the second embodiment; the electromagnetic shielding film is pressed on the printed circuit board 8, and the adhesive film layer 4 is close to the printed circuit board , specifically, the adhesi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com