Battery box with heat dissipation structure

A technology of heat dissipation structure and battery box, applied in the direction of secondary batteries, structural parts, battery pack parts, etc., can solve the problems of heat generation, not easy to dissipate heat, and affecting the time required for the battery to be fully charged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0034] An embodiment of a battery box with a heat dissipation structure of the present invention:

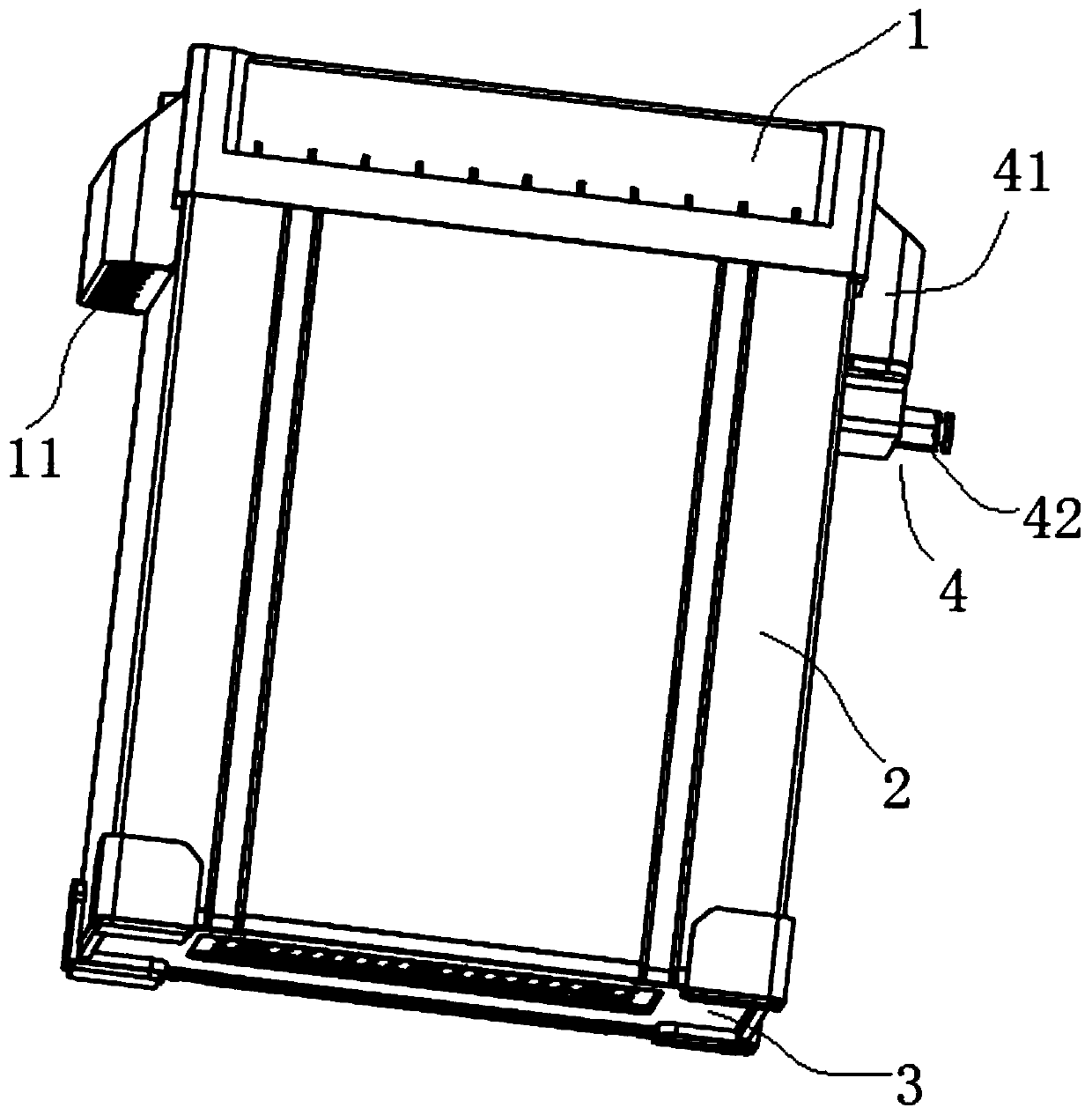

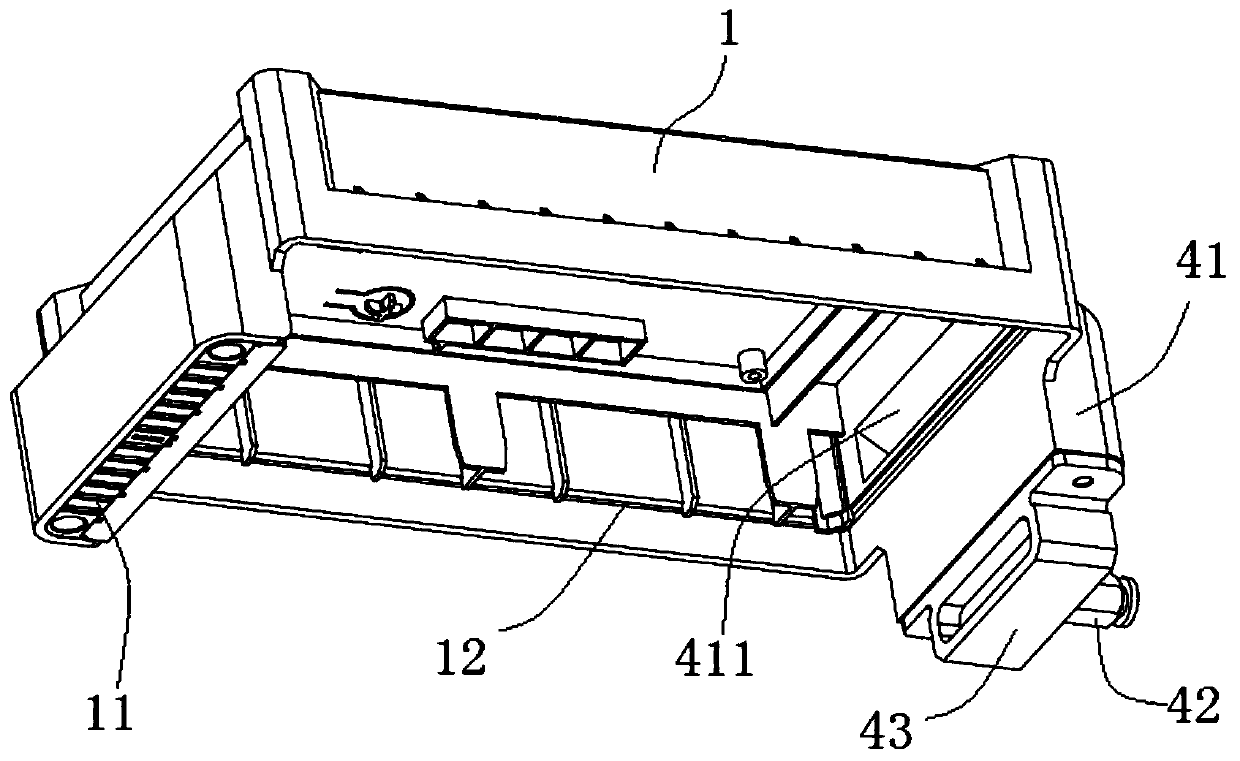

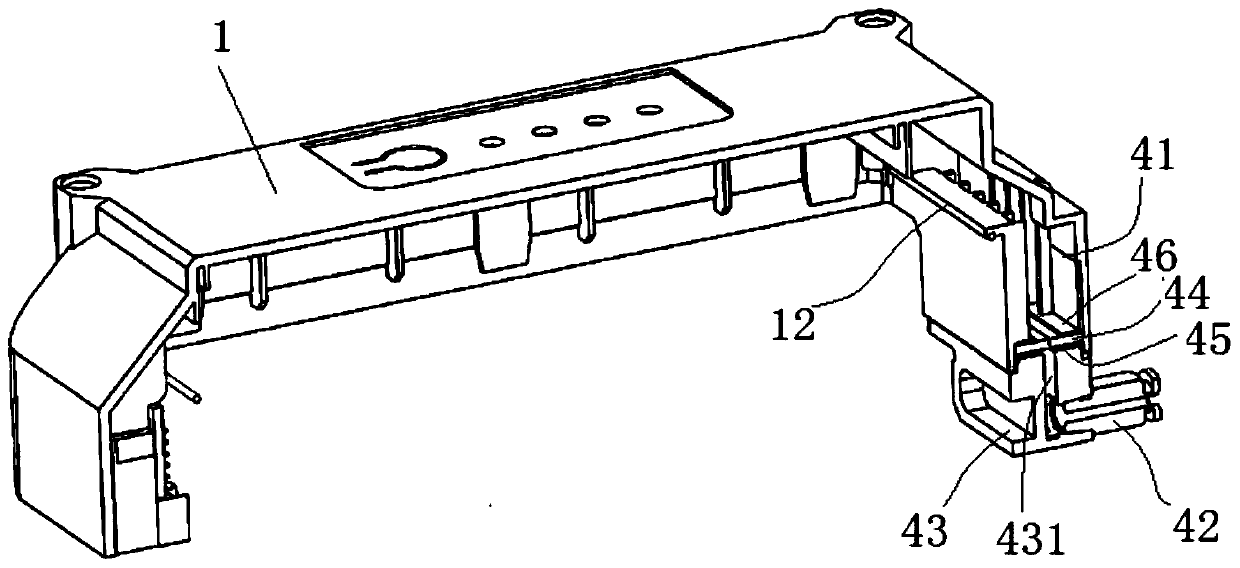

[0035] Such as Figure 1-Figure 10 As shown, the battery box with a heat dissipation structure includes an outer shell and a battery assembly. The outer shell includes an upper shell 1, a middle shell 2, and a lower shell 3. The three are fixed by screws. The upper shell 1 and the middle shell 2 The joints of the middle housing 2 and the lower housing 3 are provided with sealing rings, which are respectively recorded as the upper sealing ring 12 and the lower sealing ring 30. The left side of the upper housing 1 is provided with a charging socket 11, which is mated with a charging plug when charging. The right side of the upper casing 1 is provided with a one-way air inlet str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com