Chemical process fault diagnosis method for Bayesian network based on mechanism correlation analysis

A technology of Bayesian network and correlation analysis, applied in the field of chemical process fault diagnosis based on Bayesian network based on mechanism correlation analysis, to achieve good fault propagation path interpretation, improve calculation accuracy, and improve root cause diagnosis capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

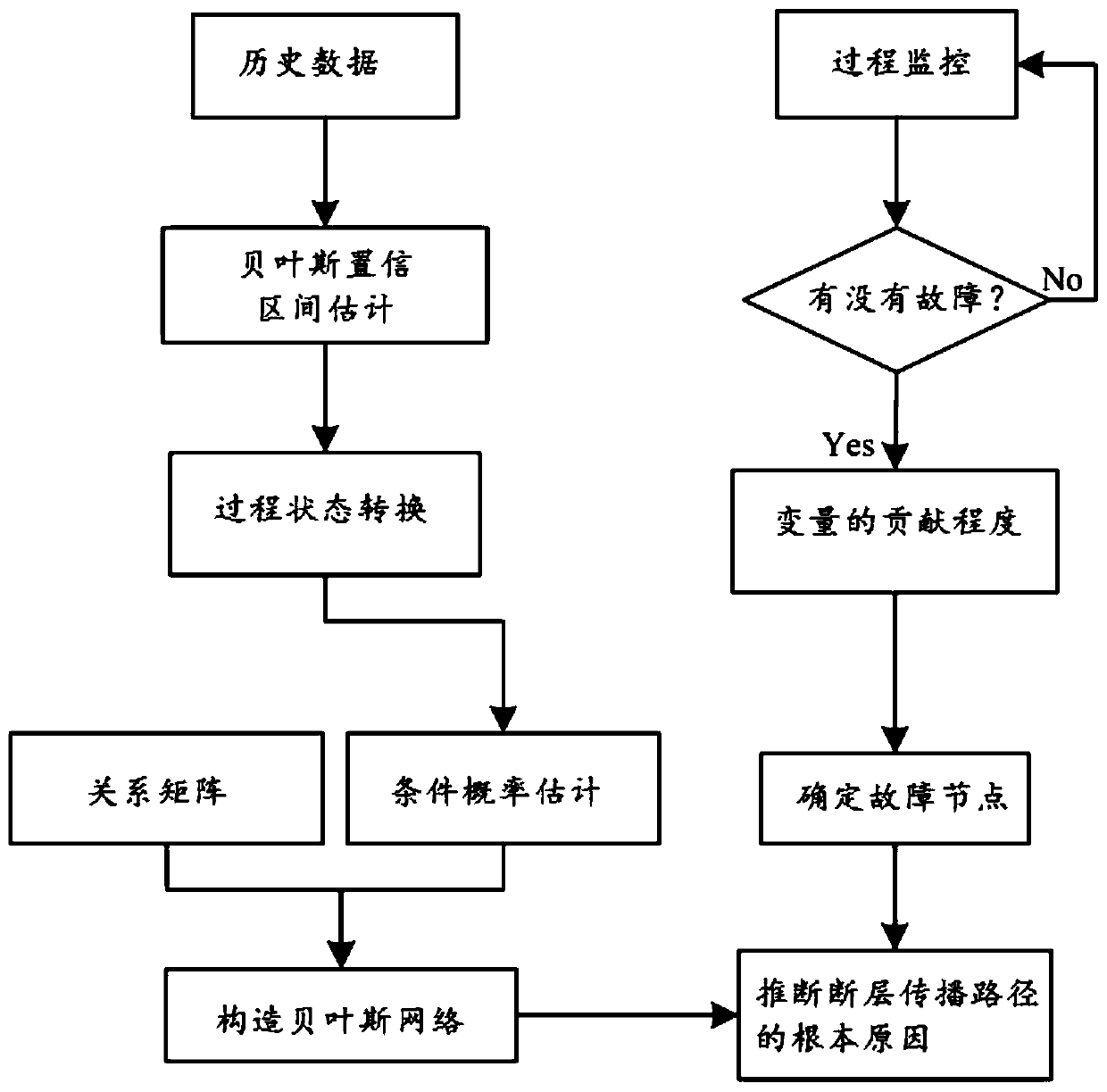

[0057] like Figure 1-6 As shown, Embodiment 1 of the present disclosure provides a chemical process fault diagnosis method based on mechanism correlation analysis Bayesian network, including the construction of Bayesian network and Bayesian model reasoning, the steps are as follows:

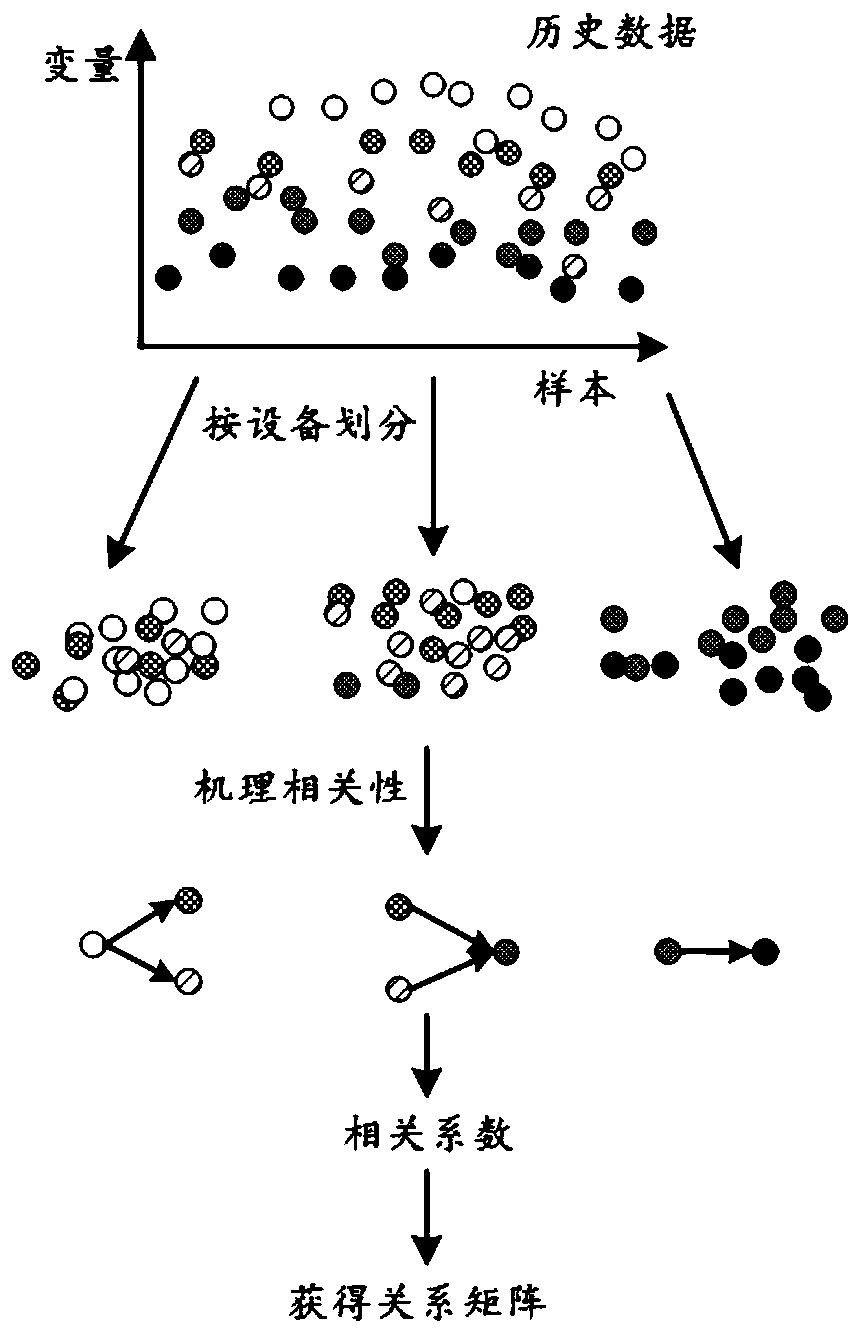

[0058] (1) Collect the historical data of the chemical process, divide the variables of the chemical process into units, analyze the mechanism correlation relationship between the unit variables of the chemical process, and obtain the relationship matrix;

[0059] (2) Use the confidence interval estimation of historical data to calculate the conditional probability of the Bayesian network, and combine the relationship matrix to establish the Bayesian network;

[0060] (3) The process is monitored by principal component analysis, and when a fault is detected, the data state transition is performed and the Bayesian contribution of the variable is calculated;

[0061] (4) Add the evidence of the f...

Embodiment 2

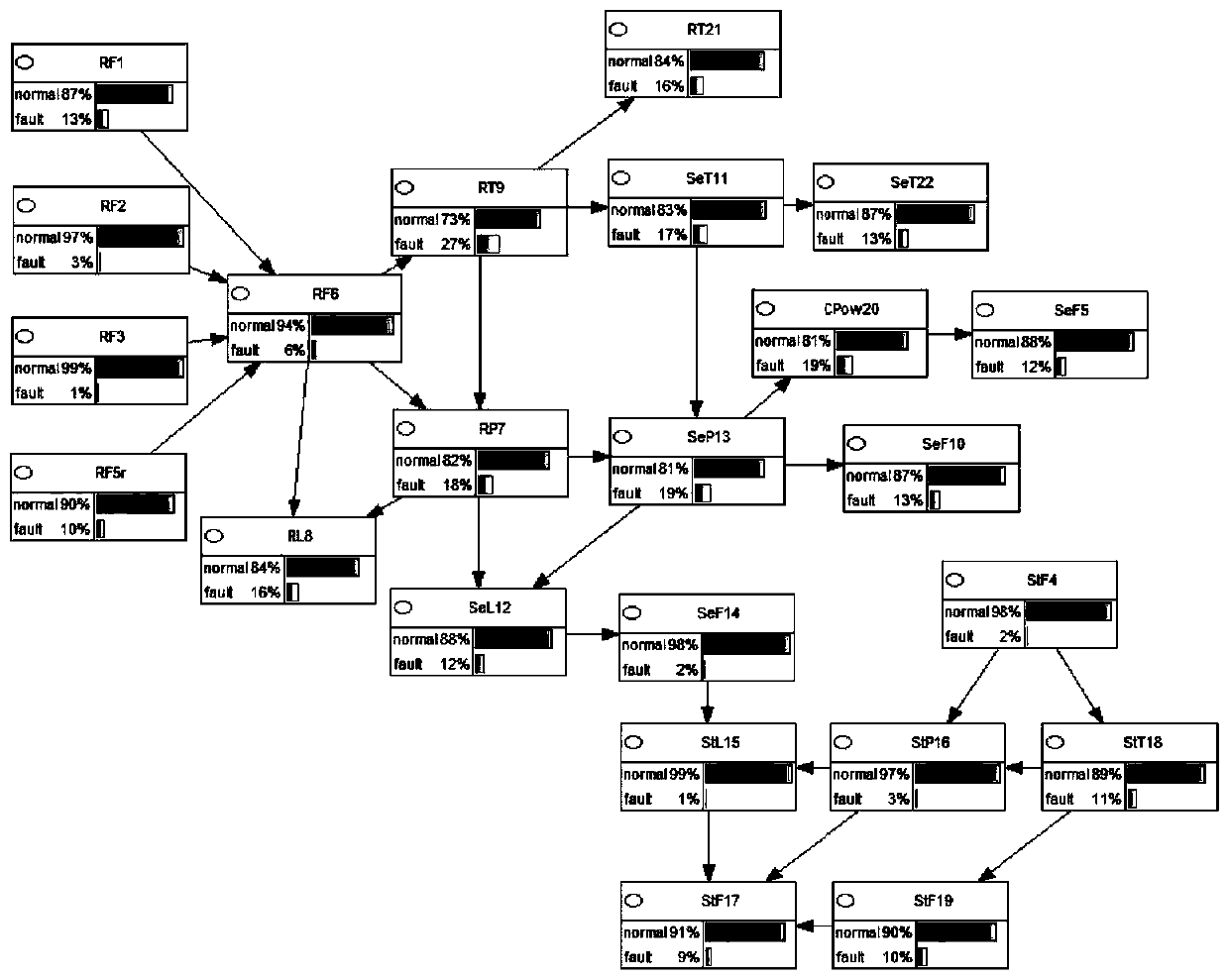

[0103] Embodiment 2 of the present disclosure provides a chemical process fault diagnosis method based on mechanism correlation analysis Bayesian network. Taking depropanization fault 1 as an example for fault diagnosis, the obtained GeNIe software visualized depropanization Bayesian network, as shown in Figure 7 as shown, Figure 8 The Bayesian network under the depropanization fault 1 visualized by GeNIe software can clearly see the relationship between the variables; the Bayesian contribution degree diagram of the variables under the depropanization fault 1 is as follows Figure 9 As shown, the obtained fault propagation path, such as Figure 10 shown by Figure 8 , Figure 9 and Figure 10 , the corresponding fault propagation path and fault root node can be clearly found, and the real cause of the fault can be obtained according to the fault propagation path and root node, combined with the mechanism-related process knowledge, the root cause of the fault can be found ...

Embodiment 3

[0105] Embodiment 3 of the present disclosure provides a chemical process fault diagnosis system based on mechanism correlation analysis Bayesian network, including:

[0106] The data acquisition and preprocessing module is configured to: collect historical data of the chemical process, divide the variables of the chemical process into units, analyze the mechanism correlation relationship between the unit variables of the chemical process, and obtain a relationship matrix;

[0107] The Bayesian network construction module is configured to: calculate the conditional probability of the Bayesian network by using the confidence interval estimation of historical data, and establish the Bayesian network in combination with the relationship matrix;

[0108] The failure analysis module is configured to: monitor the process by principal component analysis, perform data state transition when a failure is detected, and calculate Bayesian contributions of variables;

[0109] The fault dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com