Rotary excavating drilling system and soil and underground water in-situ repair process adopting same

A groundwater and drill bit technology, applied in the field of stratum restoration, can solve the problems of uneven mixing of chemicals with soil and groundwater, small diffusion radius of chemicals, unsatisfactory restoration effect, etc., so as to shorten the restoration construction period, enhance the jet cutting ability, and improve the restoration efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

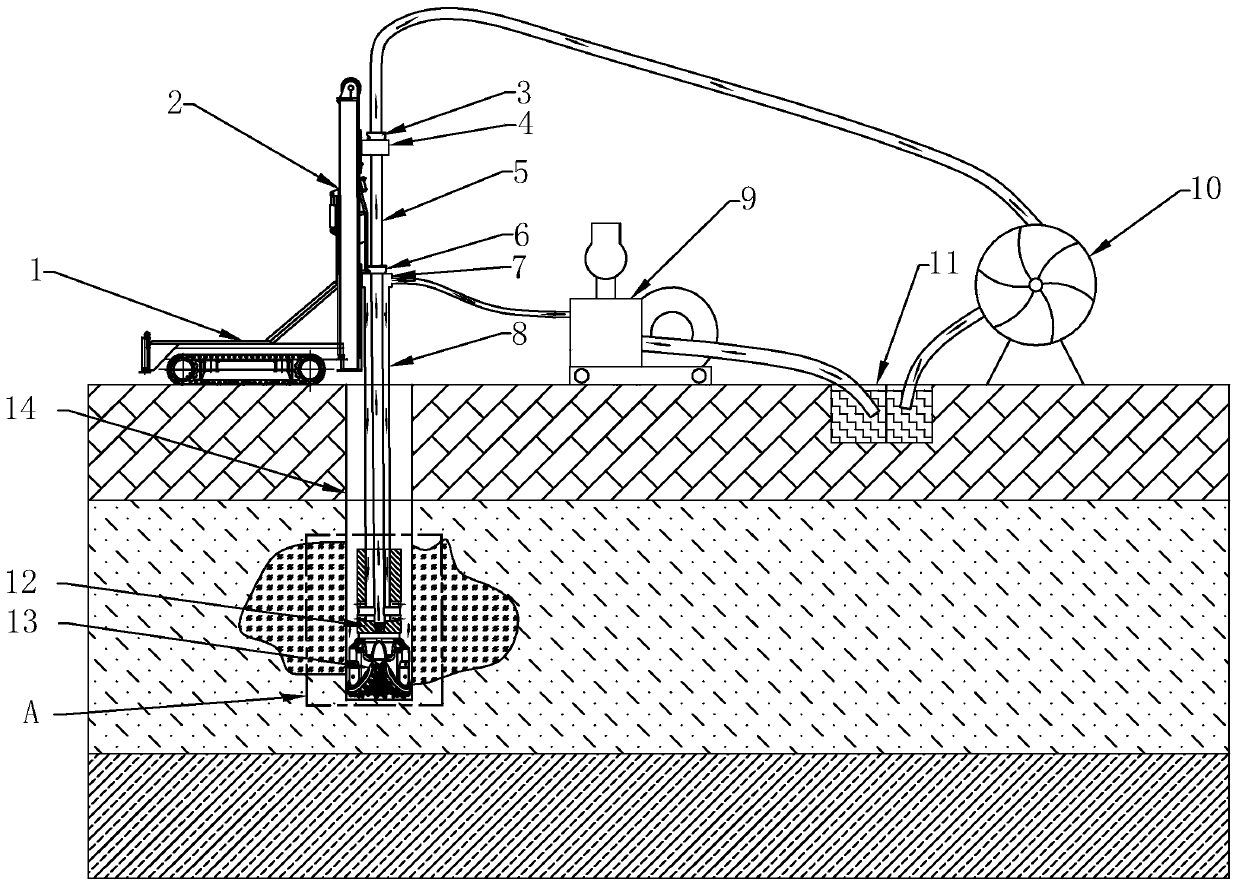

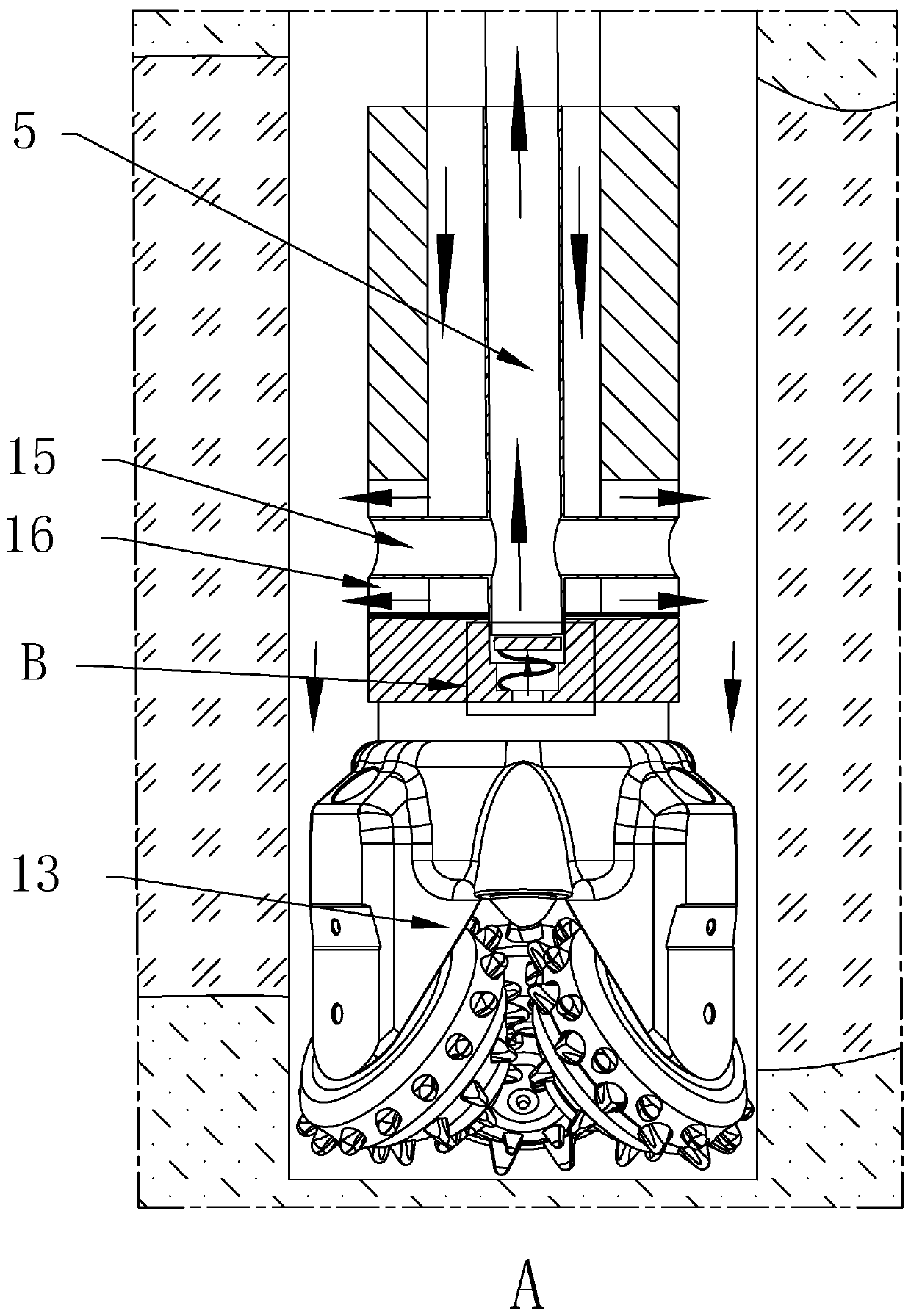

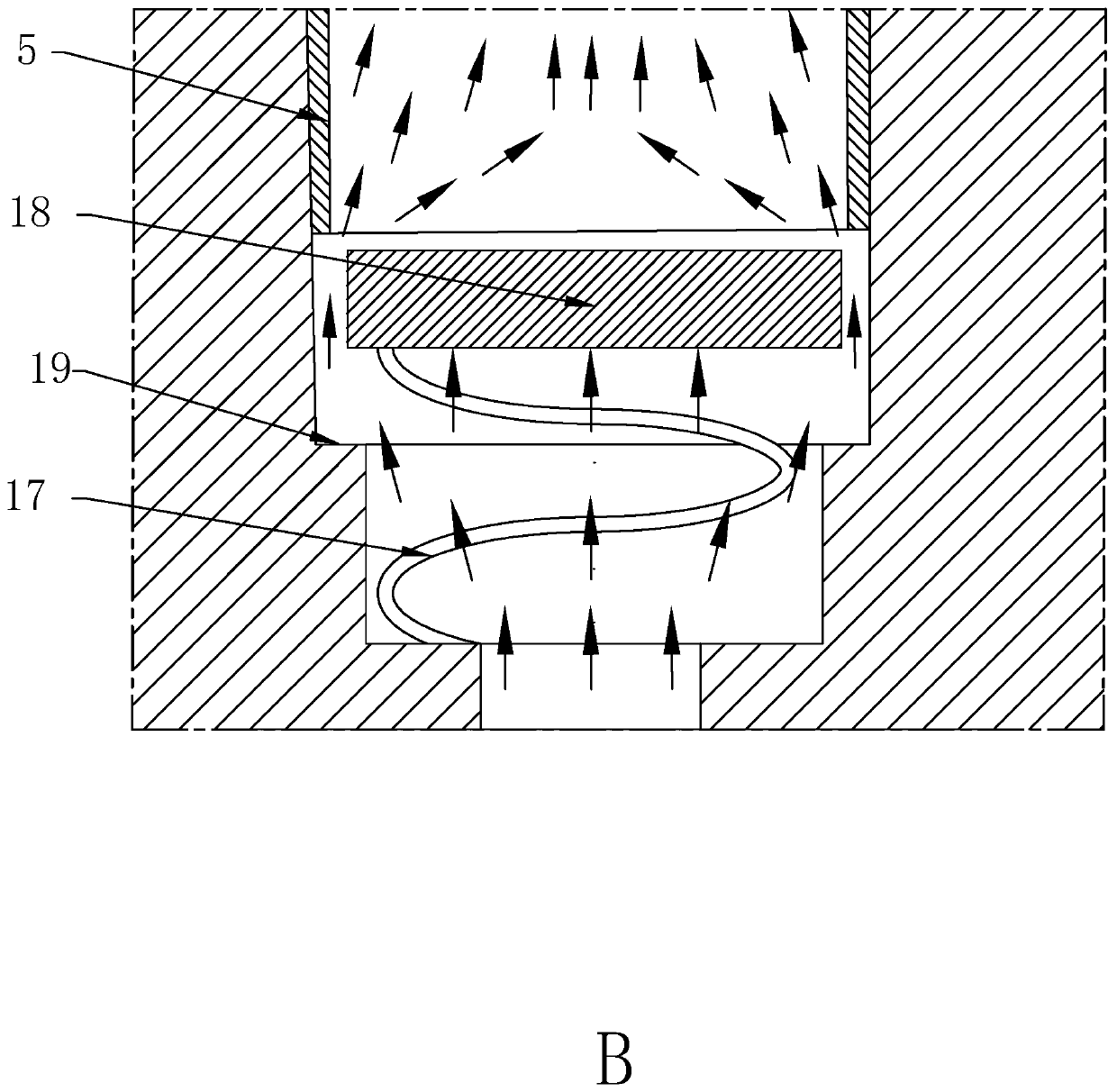

[0042] Such as figure 1As shown, a rotary drilling system includes an inner pipe 5, an outer pipe 8, a jet nipple 12 and a drill bit 13. The inner pipe 5 is rotatably supported in the outer pipe 8, and the inner pipe 5 and the outer pipe 8 are respectively driven by corresponding power. head drive; one end of the outer pipe 8 drilled is socketed with a spray nipple 12, and the end of the jet nipple 12 away from the outer pipe 8 is connected to the drill bit 13; the jet nipple 12 includes a plurality of spray ports evenly opened in the radial direction, Inner tube 5 and outer tube 8 correspond to the injection ports and have coaxial water holes, the inner diameter of the water holes offered on the inner tube 5 is smal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com