Plating pretreatment device for cylinder electroplating

A processing device and cylinder technology, applied in the direction of electrolysis components, electrolysis process, etc., can solve the problems of increased loss, instability, incompatibility of single-cylinder/double-cylinder products, etc., to achieve short switching time, meet delivery requirements, and avoid production capacity. effect of loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

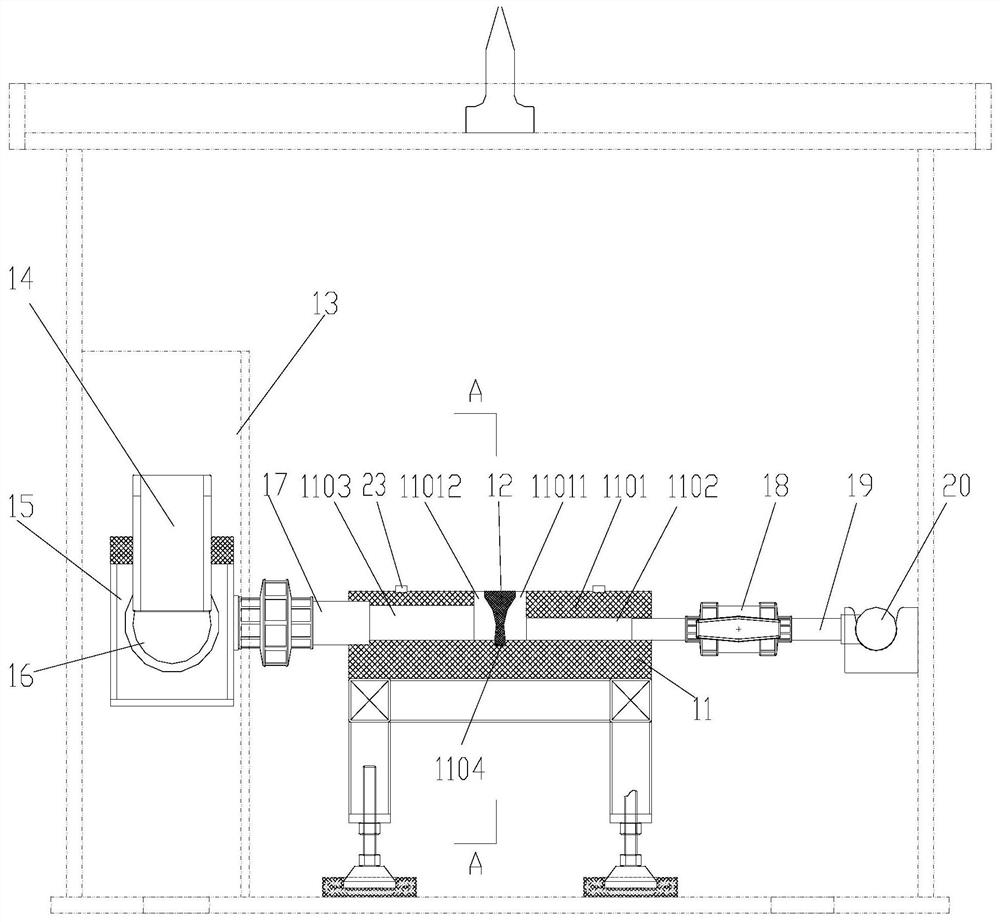

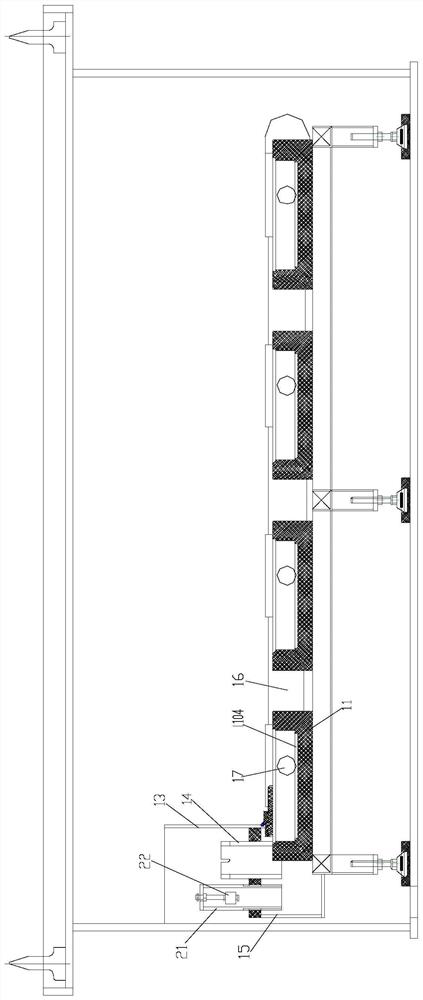

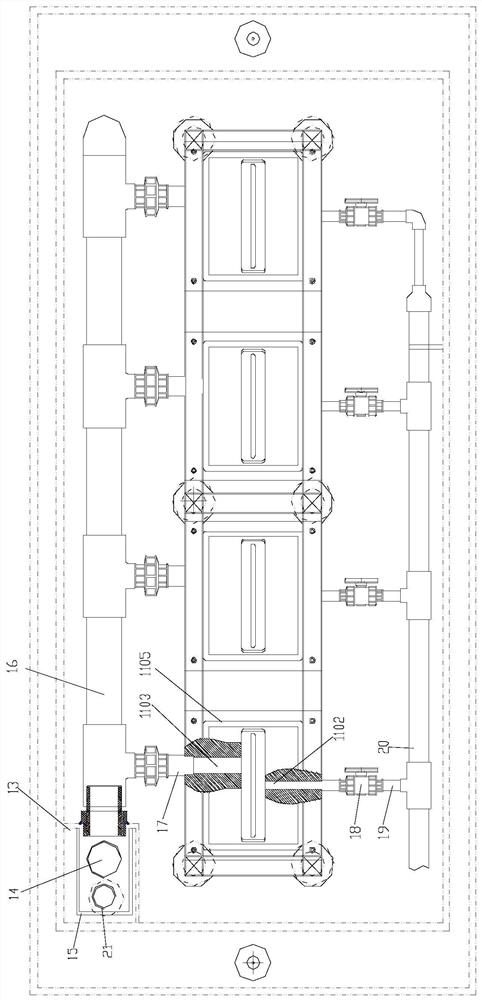

[0030] figure 1 It is a structural sectional view of the present invention, figure 2 for figure 1 A-A sectional view, image 3 for figure 2 top view of Figure 4 For the present invention using a state diagram, Figure 5 for Figure 4 The enlarged view at B, as shown in the figure: the pre-plating treatment device for cylinder electroplating in this embodiment includes a processing unit, a liquid supply component and a liquid return component;

[0031] The processing unit includes a base body 11, and the base body 11 has an upper plane 1101 on which a tooling is placed, and the tooling is used for installing workpieces;

[0032]The base body has a liquid inlet 11011 and a liquid return port 11012 on its upper plane, and the workpiece inner cavity (the part to be treated) communicated with the liquid inlet 11011 and the liquid return port 11012 behind the upper plane 1101 of the tooling device The tooling of this embodiment can be any tooling that can realize cyclic el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com