Anode carbon block vibration forming machine

A technology of vibration molding machine and anode carbon block, which is applied in the field of electrolytic aluminum, can solve the problems of inconvenient maintenance and disassembly of equipment, and achieve the effects of improving production efficiency, improving measurement accuracy, and accurate actual weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

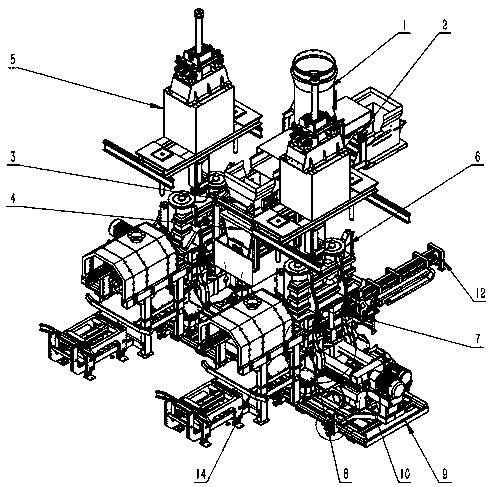

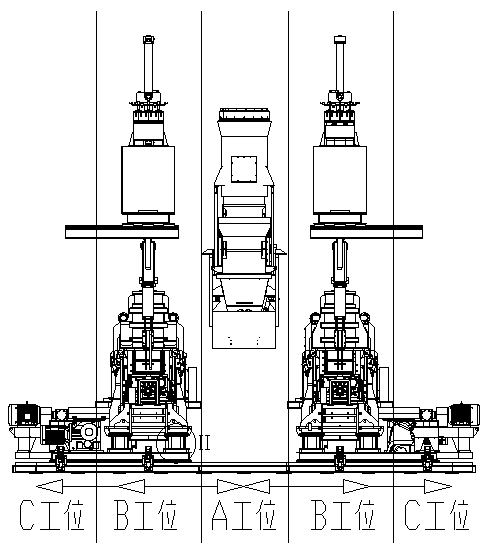

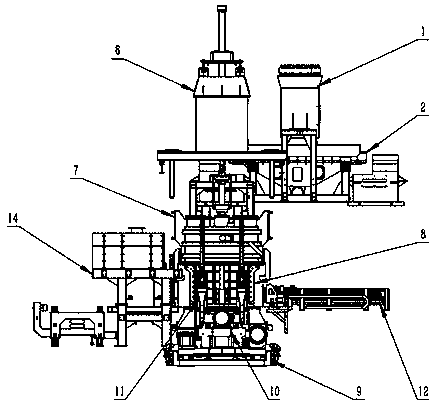

[0080] like figure 2 As shown, station A-receiving station; station B-production station; station C-maintenance station, station A-receiving station below the static weighing hopper 4; station B below the weight 6-production station. The storage hopper 1, the feeder 2, the distributor 3 and the static weighing hopper 4 are located at the A station, and the heavy hammer member is located at the B station. During operation, the mold 7 and the vibrating table 8 are transported to the receiving position A by the vibrating table conveying device 9, and are located below the static weighing hopper 4.

[0081] The static weighing hopper 4 accurately weighs the paste through the static state, and automatically adjusts the level of the paste entering the mold 7 through the second distributing plate 4-4. The static state means that the weighing hopper is in a static state. However, the weighing of imported and other domestic conveying trolleys is in a dynamic weighing state, which is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com