Collagen extraction tank

A technology for collagen and plastic tanks, which is applied to the preparation methods of animal/human proteins and peptides, connective tissue peptides, etc. It can solve the problems of deformation of stirring blades, difficulty in controlling the direction of feeding, and easy smashing of stirring blades, etc. , to achieve the effects of reducing the chance of impact, improving structural strength, and reducing the possibility of deformation and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] This embodiment proposes a collagen extraction tank that can avoid smashing the stirring blades when feeding.

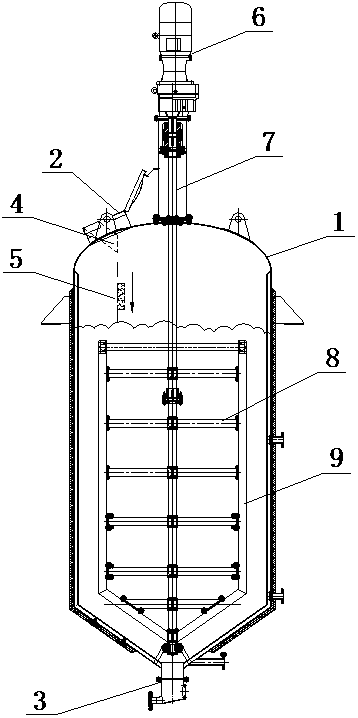

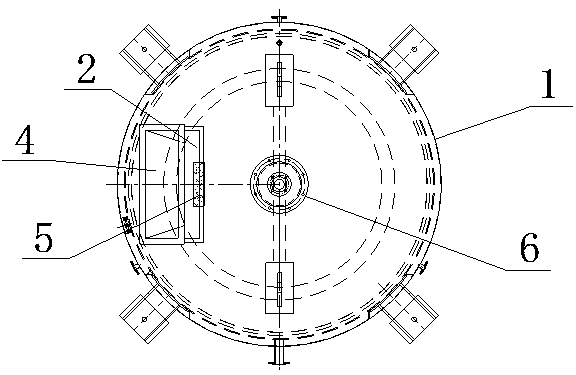

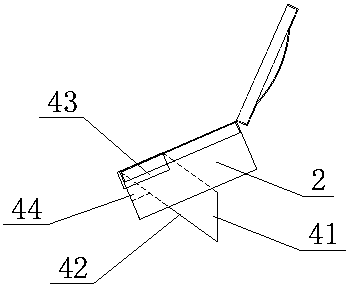

[0016] Such as figure 1 , 2 , 3, the collagen extracting tank of the present embodiment comprises a tank body 1, the top of the tank body 1 is provided with a feeding port 2, the bottom is provided with a discharge port 3, and a stirring device is also provided in the tank body 1; the key is The feeding port 2 is provided with a feeding slide 4 that extends into the inside of the tank body 1. The feeding slide 4 is a groove-shaped structure formed of groove walls 41 on both sides and an inclined groove bottom 42 at the bottom. The two sides of the feeding slide 4 The side tank wall 41 is provided with a flanging 43, and the feeding slide 4 is erected at the feeding port 2 by using the flanging 43, and the bottom of the tank 42 is provided with a supporting plate 44 protruding downward, and the supporting plate 44 is offset against the side wall of the feeding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com