Lifting device for hot galvanizing production

A lifting device and hot-dip galvanizing technology, applied in cranes, hot-dip galvanizing, trolley cranes, etc., to avoid deviation, avoid changes, and ensure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0017] Example 1

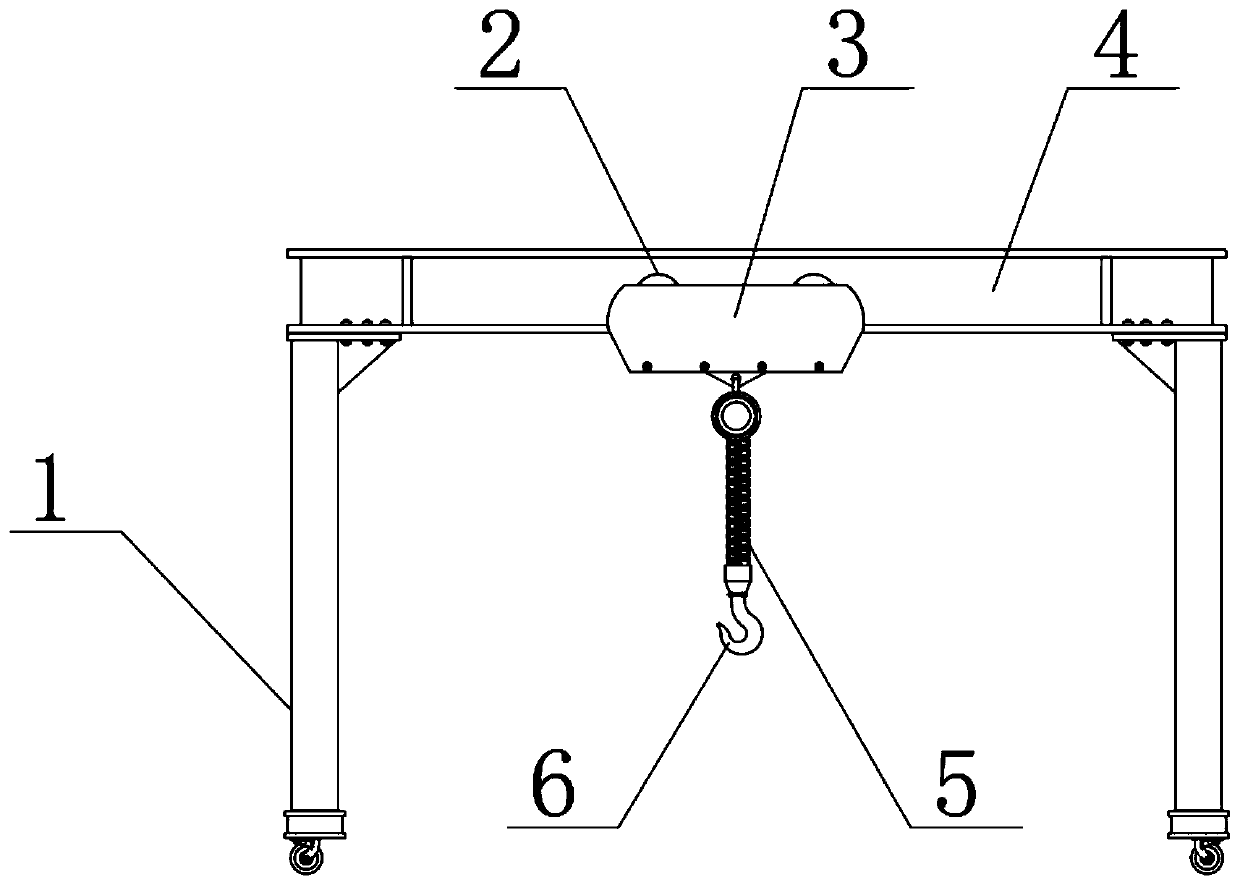

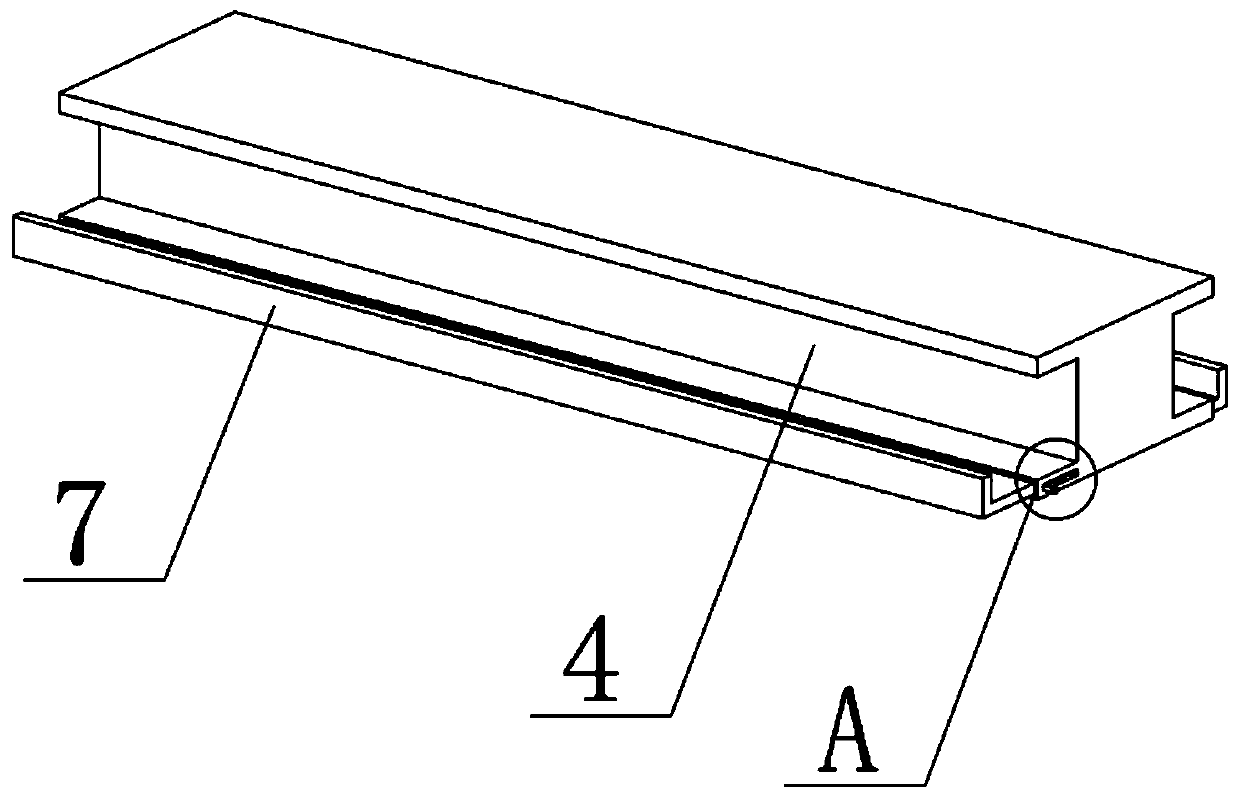

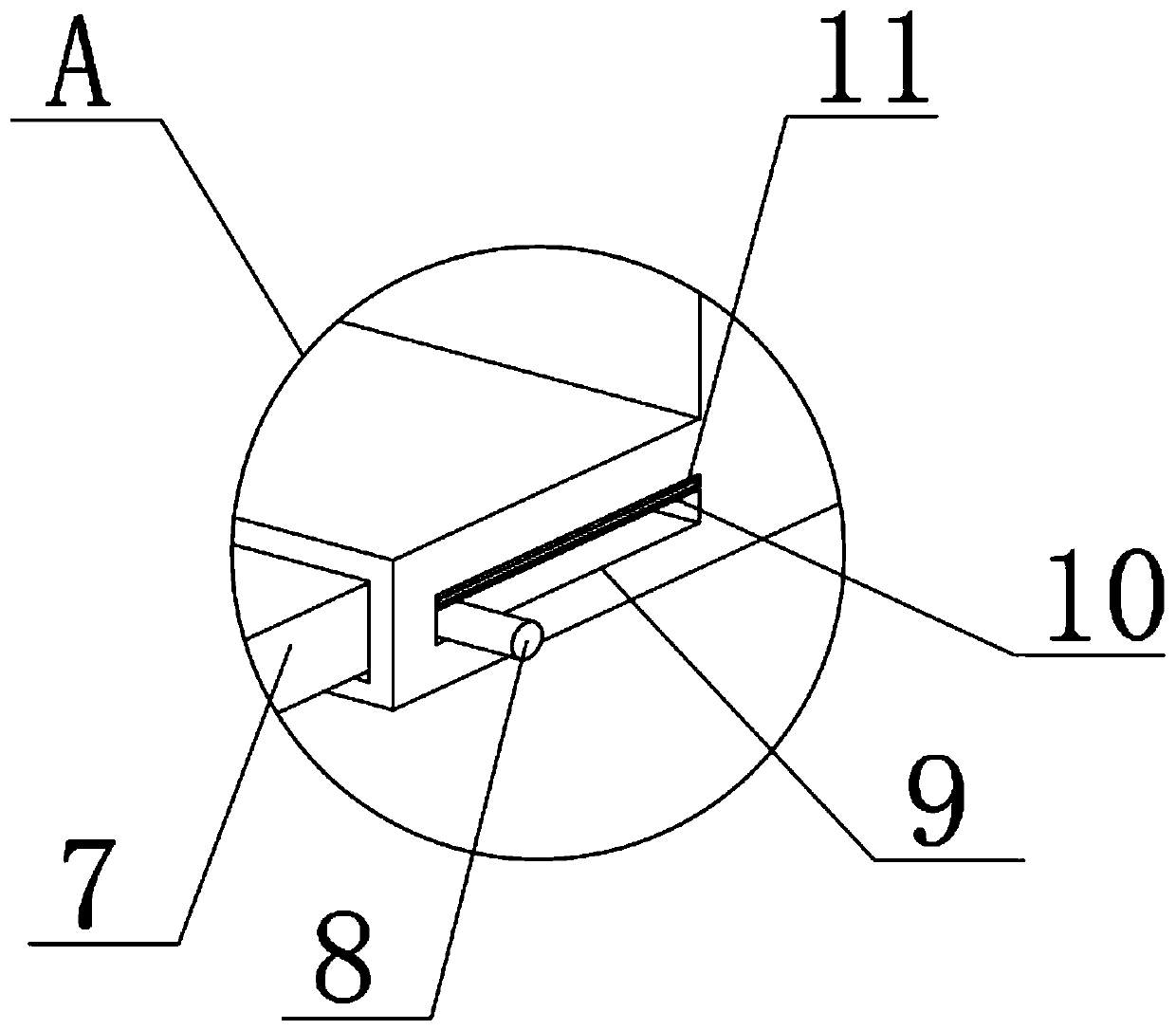

[0018] See Figure 1 to Figure 3 , The present invention provides a technical solution: a lifting device for hot-dip galvanizing production, comprising a main beam 4 with an "I"-shaped cross section, a shell 3 is provided at the bottom of the main beam 4, Rollers 2 are installed on both sides of the inner wall. Rollers 2 are inside the main beam 4. The bottom edge of the main beam 4 is convex, and the convex interior is provided with a horizontally movable limit plate 7, and the limit plate 7 The cross section is an L-shaped structure. The convex side is provided with a sliding groove 9. The inner side of the sliding groove 9 penetrates the adjusting column 8. The end of the adjusting column 8 is fixedly connected with the side of the limiting plate 7. The limiting plate 7 The inner side of the roller 2 is attached to the side of the roller 2, through the designed limit plate 7, the position of the roller 2 can be limited in use, to avoid the deviation of the ...

Example Embodiment

[0023] Example 2

[0024] The difference with this embodiment 1 is: please refer to figure 1 , figure 2 with Figure 4 , A lifting device for hot-dip galvanizing production, comprising a main beam 4 with an "I"-shaped cross section, a shell 3 is provided at the bottom of the main beam 4, and rollers 2 are installed on both sides of the inner wall of the shell 3. The roller 2 is located on the inner side of the main beam 4, the bottom edge of the main beam 4 is convex, and a horizontally movable limit plate 7 is arranged inside the convex shape. The cross section of the limit plate 7 is an L-shaped structure, convex A chute 9 is provided on the raised side. The inner side of the chute 9 penetrates the stud 12, and the end of the stud 12 is fixedly connected to the side of the limit plate 7, and the inner side of the limit plate 7 is connected to the side of the roller 2. For edge-fitting connection, the designed limit plate 7 can limit the position of the roller 2 during use to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com