Helical pipeline concrete automatic transport device

An automatic conveying device and concrete technology, applied in the direction of conveyor objects, transportation and packaging, packaging, etc., can solve the problems of splashing, large drop in chute conveying, self-weight, etc., and achieve high safety performance, strong stability and reasonable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

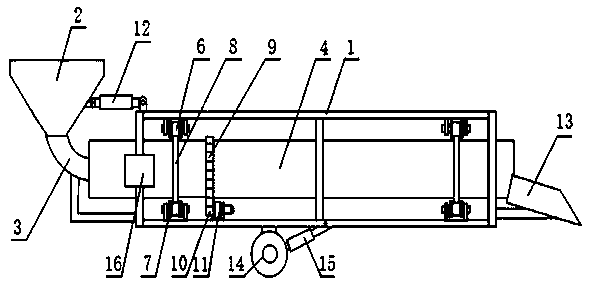

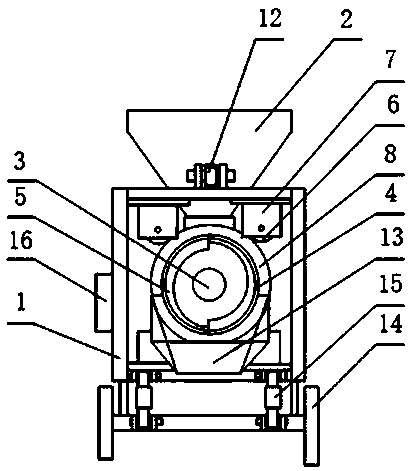

[0011] The present invention will be described in further detail below in conjunction with accompanying drawing:

[0012] The frame 1 is a frame type, and the wheel bases 7 are respectively fixed in the four corners of the two ends of the frame 1, the reducer 11 is installed on the inner bottom of the frame 1 and the driving gear 10 is connected, and the positioning wheels 6 are respectively installed in each wheel base 7, The conveying pipe 3 penetrates into the frame 1 and is fixed between the positioning wheels 6 at the same time. The inner wall of the conveying pipe 3 is provided with two sets of helical blades 5, and its outer edge is fixed with a circular ring 8 and snapped into the groove of the positioning wheel 6. Inside, the outer edge of the conveying pipe 3 corresponding to the driving gear 10 is installed with a ring gear 9 and meshed with it, and the feeding pipe 3 and the feeding hopper 2 are connected through the frame 1 at the left end of the conveying pipe 4, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com