A carrier tape for conveying electronic products

A technology of electronic products and carrier tapes, applied in the direction of layered products, synthetic resin layered products, conductive adhesives, etc., to achieve the effects of reducing positioning procedures, improving production efficiency, and facilitating precise clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

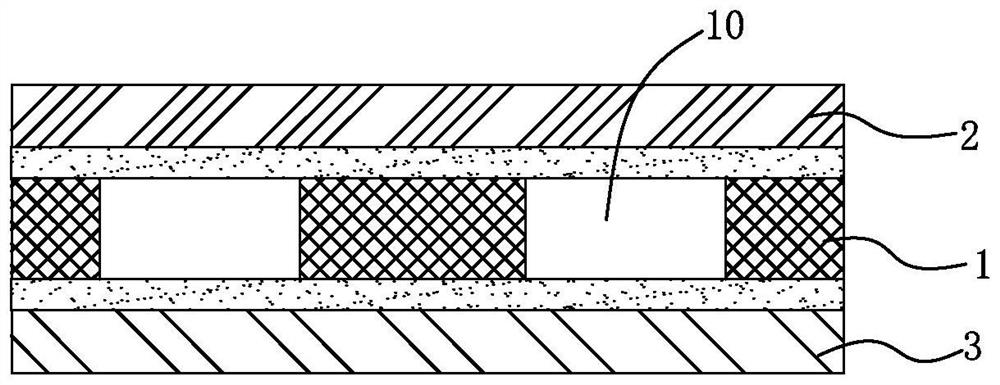

[0019] See figure 1 As shown, the present invention is a carrier tape for conveying electronic products, which includes: a substrate layer 1 , and a surface layer 2 and a bottom layer 3 respectively covering the upper and lower surfaces of the substrate layer 1 .

[0020] The base material layer 1 adopts PET Mylar sheet, that is, after a certain reinforcing material is mixed in PET (polyethylene terephthalate), its strength, rigidity and heat resistance are all improved. PET material. Usually mylar sheets are used as spacers in electronic products. In the present invention, the substrate layer 1 uses a Mylar sheet as a bearing layer. In addition, positioning holes 10 are evenly molded and distributed on the base material layer 1 by means of die-cutting. The manufacturing method is as follows: pass the formed substrate layer 1 through an automat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com