A heating furnace for polymer plastic optical fiber drawing equipment

A technology of optical fiber and drawing equipment, which is applied in the direction of lighting and heating equipment, furnace, furnace cooling, etc., can solve the problems of fiber scrapping, mutual sticking, and fiber line drooping, etc., so as to improve quality, avoid bonding, and improve The effect of smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

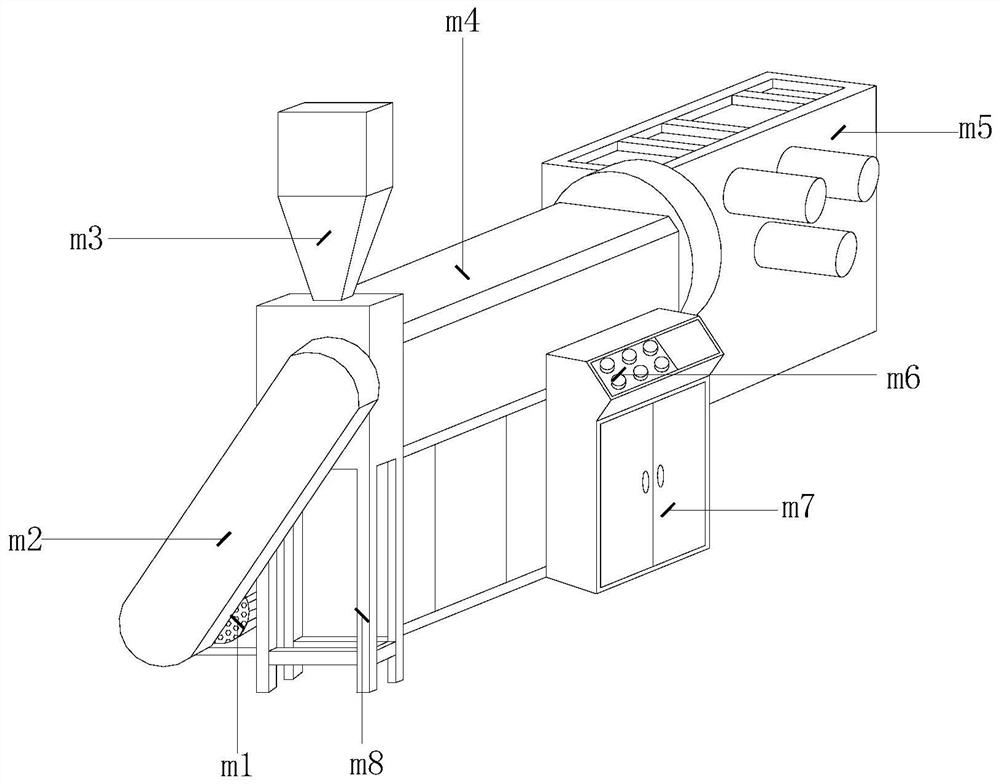

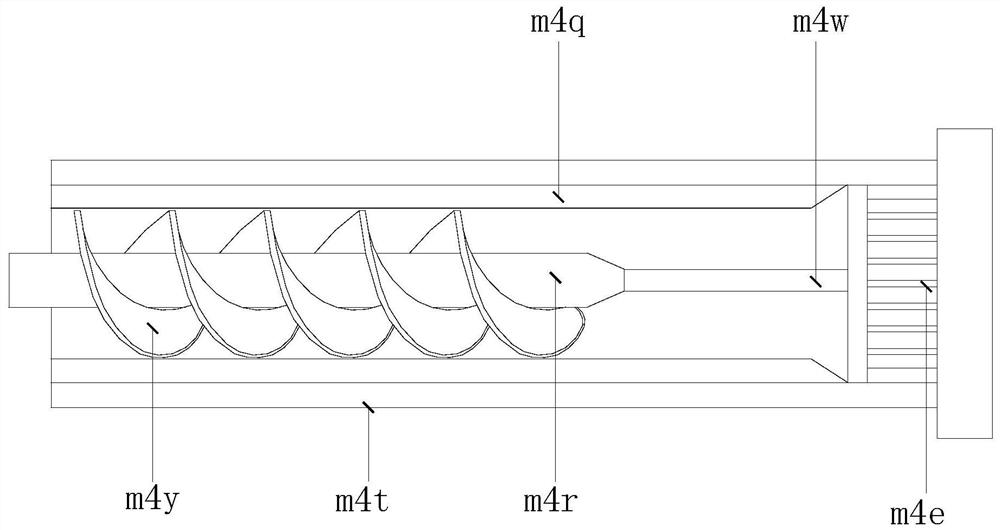

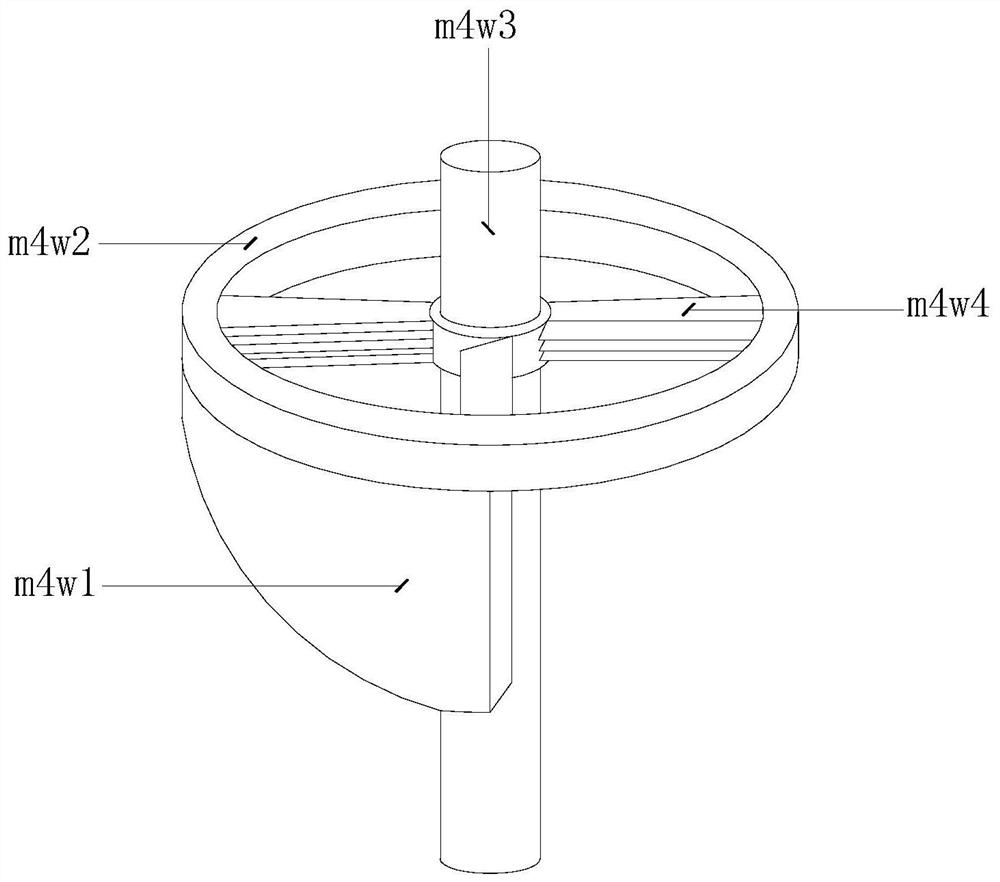

[0028] see Figure 1-Figure 6 , the present invention provides a heating furnace for polymer plastic optical fiber drawing equipment, the structure of which includes a driving motor m1, a chain mechanism m2, a feeding hopper m3, a heating mechanism m4, a wire drawing device m5, a controller m6, an inspection door m7, Assembly bracket m8, the assembly bracket m8 is installed on the front end of the heating mechanism m4 by buckling, the rear end of the heating mechanism m4 is provided with a wire drawing device m5, and the feeding hopper m3 is connected to the inside of the heating mechanism m4 through the assembly bracket m8 , the driving motor m1 is installed on the lower left side of the assembly bracket m8 by buckling, the front end of the assembly bracket m8 is provided with a chain mechanism m2, the lower end of the chain mechanism m2 is fitted and connected with the driving motor m1, and the heating mechanism m4 The front end is meshed with the upper end of the chain mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com