Metal surface galvanizing device and method

A metal surface and treatment device technology, applied in metal material coating process, hot-dip plating process, coating, etc., can solve problems such as easy to rust and affect the service life of metal pipes, so as to improve uniformity and service life , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

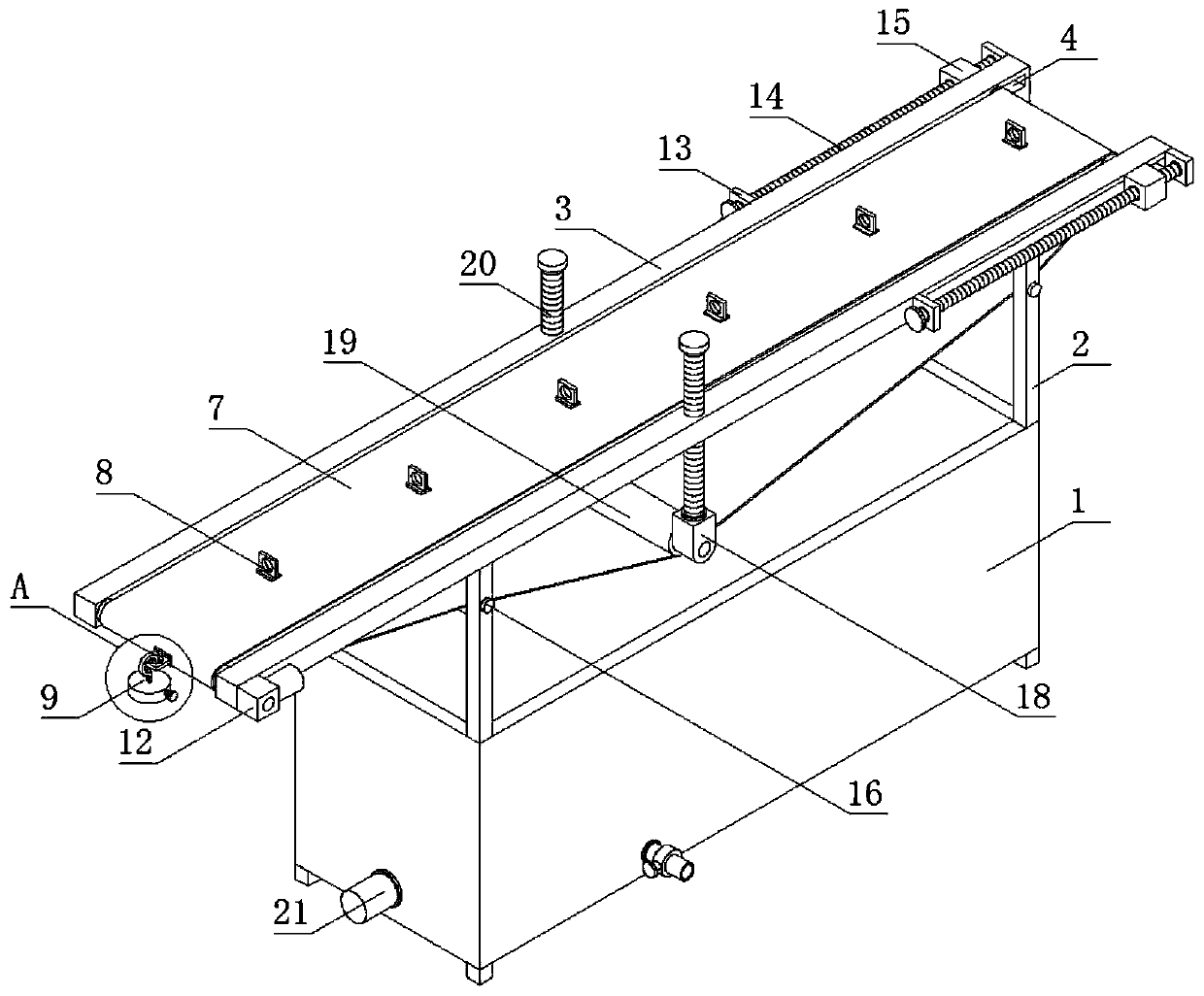

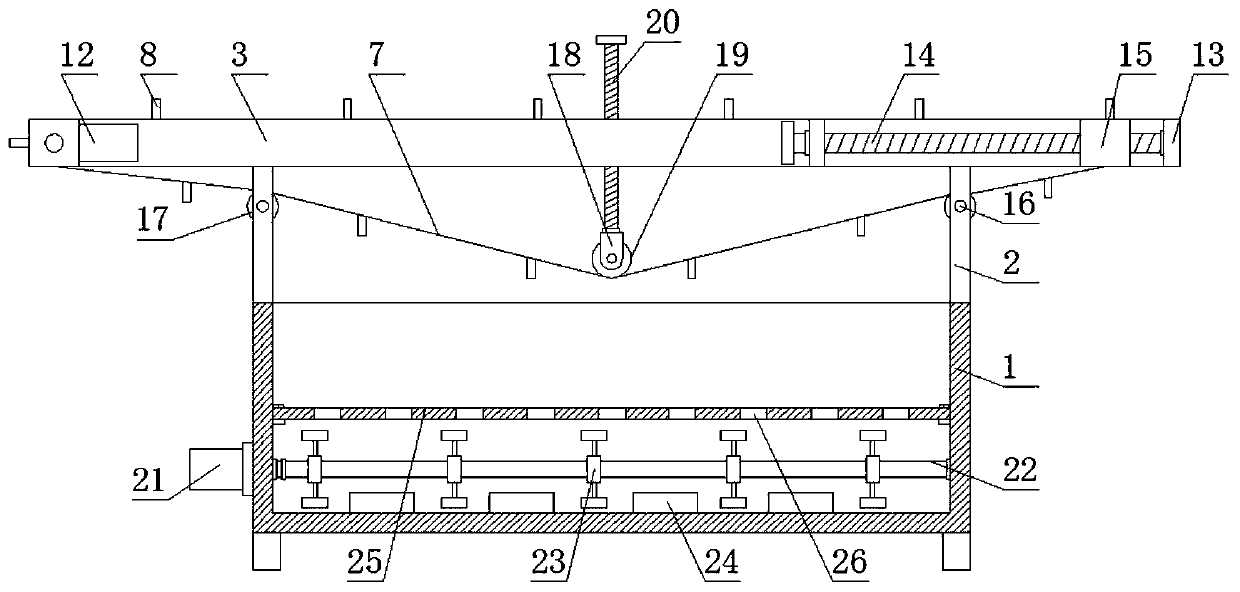

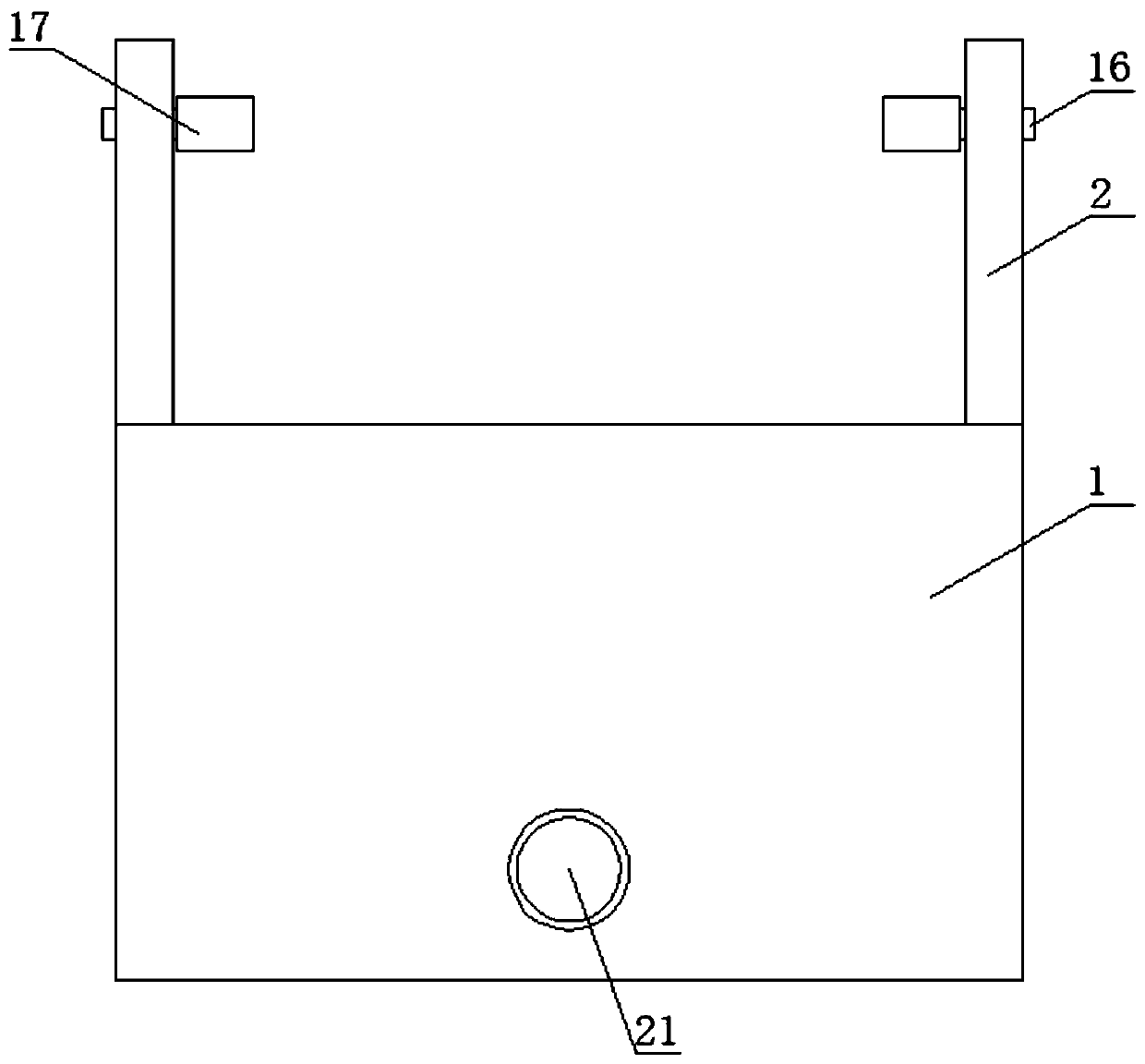

[0036] Example: such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, a metal surface galvanizing treatment device and method of the present invention includes a galvanizing pool 1, four ends of the top of the galvanizing pool 1 are fixedly equipped with columns 2, and two supports are arranged between the tops of the four columns 2 plate 3, a conveying mechanism is arranged between the two support plates 3, and the conveying mechanism is composed of a drive motor 12, two rotating shafts 5, two transmission rollers 6, a transmission belt 7, several hanging rings 8 and several fixed components, The right sides of the two support plates 3 are provided with square holes 4, and the two ends of one of the rotating shafts 5 are respectively connected to the two support plates 3 through bearings, and the driving motor 12 is fixedly installed on one side of one of the support plates 3, and the support plate The output shaft of 3 is connected with one of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com