High-performance polytetrafluoroethylene film, and manufacturing method of microwave substrate thereof

A technology of polytetrafluoroethylene and its manufacturing method, which is applied in the field of communication, can solve the problems of easy tearing of film, thick texture of PTFE varnished cloth, poor appearance, etc., and achieve the problems of poor adhesion, stable dielectric constant, and reduced water absorption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

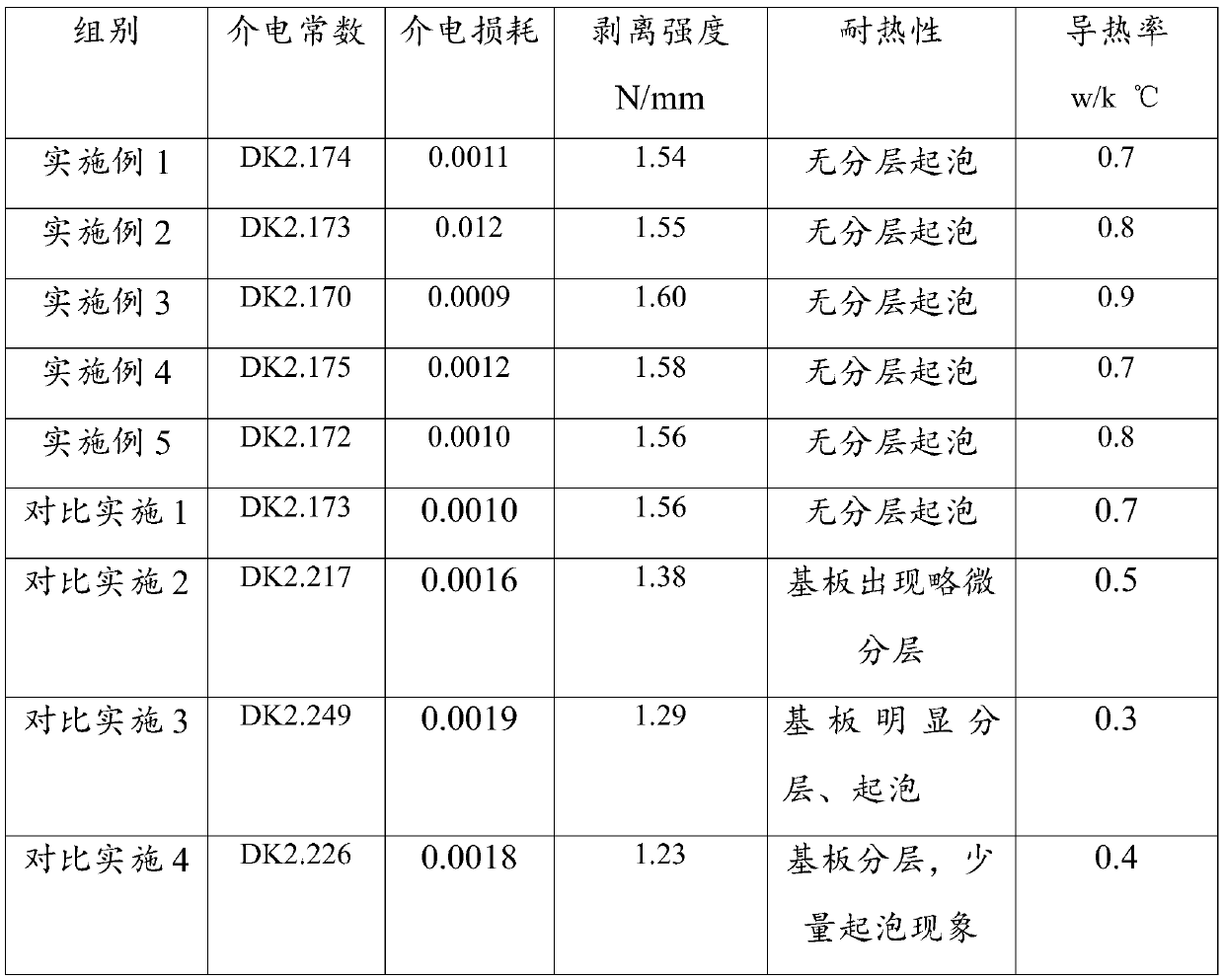

Examples

Embodiment 1-5

[0033] Embodiment 1-5 Preparation of PTFE film and microwave substrate thereof

[0034] Embodiment 1-5 prepares the formula of PTFE film as follows:

[0035] components Example 1 Example 2 Example 3 Example 4 Example 5 Glass fiber / g 3 4 15 24 49 Cationic polyurethane / g 6 3 12 20 14 Nano silicon nitride / g 1 3 9 8 7 PTFE resin / g 30 45 50 60 90

[0036] Embodiment 1-5 prepares the method for PTFE film as follows:

[0037] S1. Put nano-silicon nitride, glass fiber, and cationic polyurethane filler into PTFE resin, disperse it by ball milling, and keep the obtained glue for more than 8 hours;

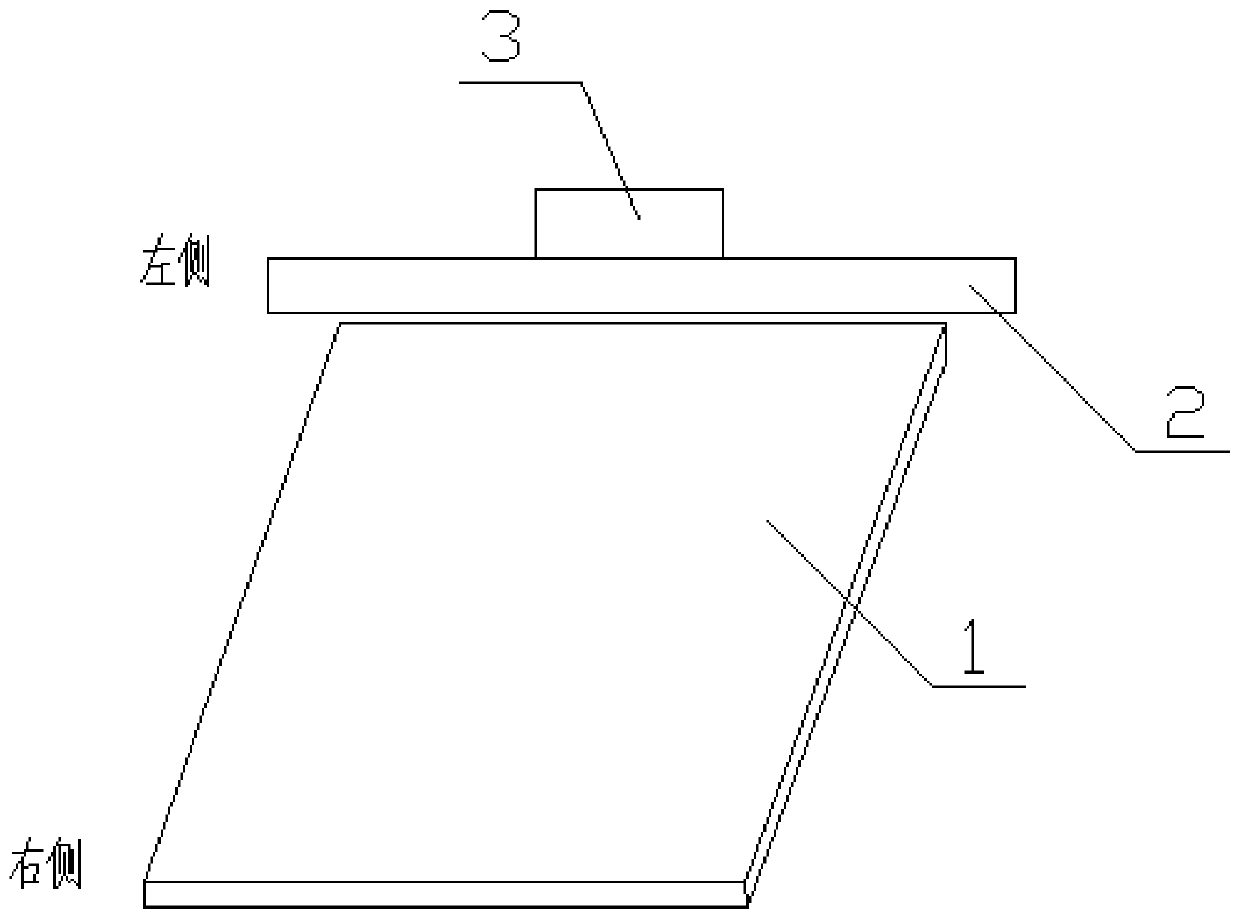

[0038] S2. Take the heat-resistant tempered glass equipped with measuring rollers that can continuously move left and right. The heat-resistant tempered glass has a thickness of 0.5 cm, a roughness of Ra 0.020 um, a width of 1000 mm, and a length of 1000 mm. Place the heat-resistant tempered glass horizontally, and determine t...

Embodiment 6-9

[0044] Embodiment 6-9 Preparation of PTFE film and microwave substrate thereof

[0045] The preparation method refers to Example 3, the difference is that the number of PTFE film sheets is different when preparing the PTFE film microwave substrate, and the number of sheets in Examples 6-9 is 2, 3, 5, and 7 respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com