Method for realizing vertical butt joint, pressing or separation of light-type aviation connector plug

A technology of aviation connectors and aviation plugs, which is applied in the direction of connection, parts of connecting devices, contact parts, etc., can solve the problem of one-time use and non-reusability of detached connectors, and achieves good vertical docking and pressing, and smooth separation. no damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the simplified structural diagram shown in the accompanying drawings.

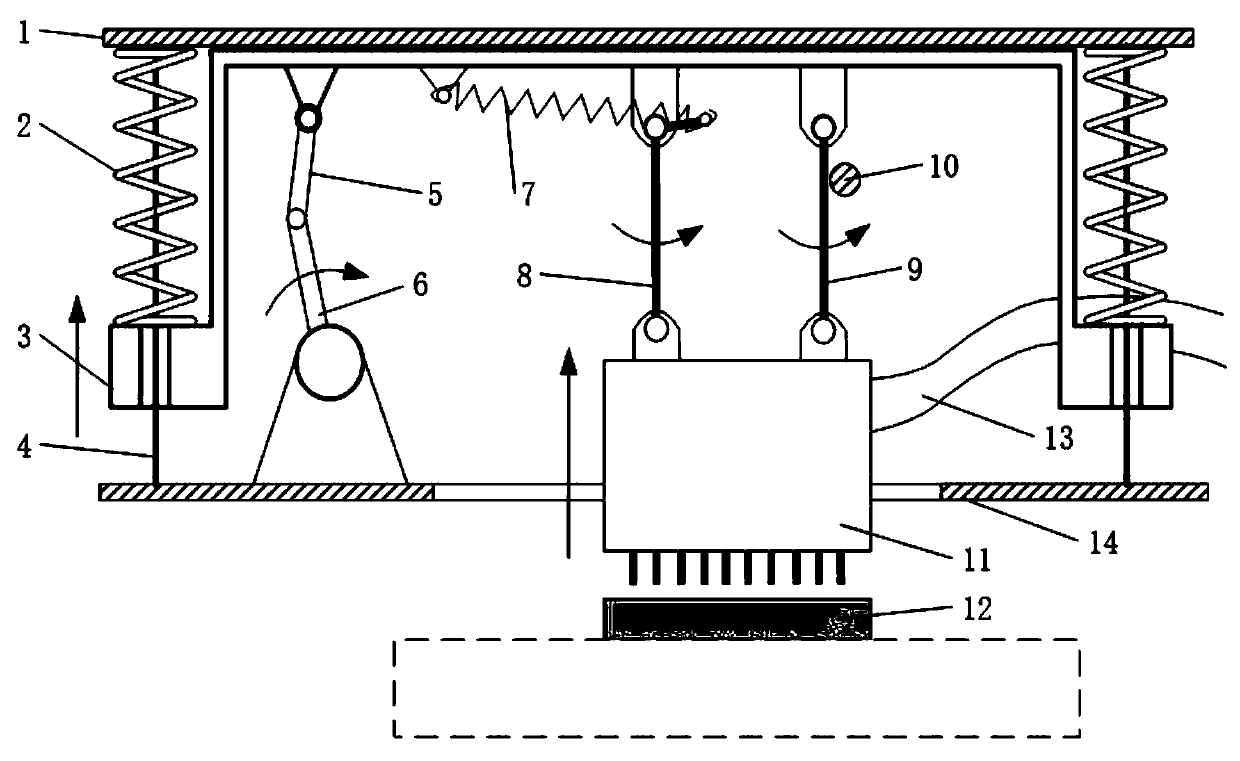

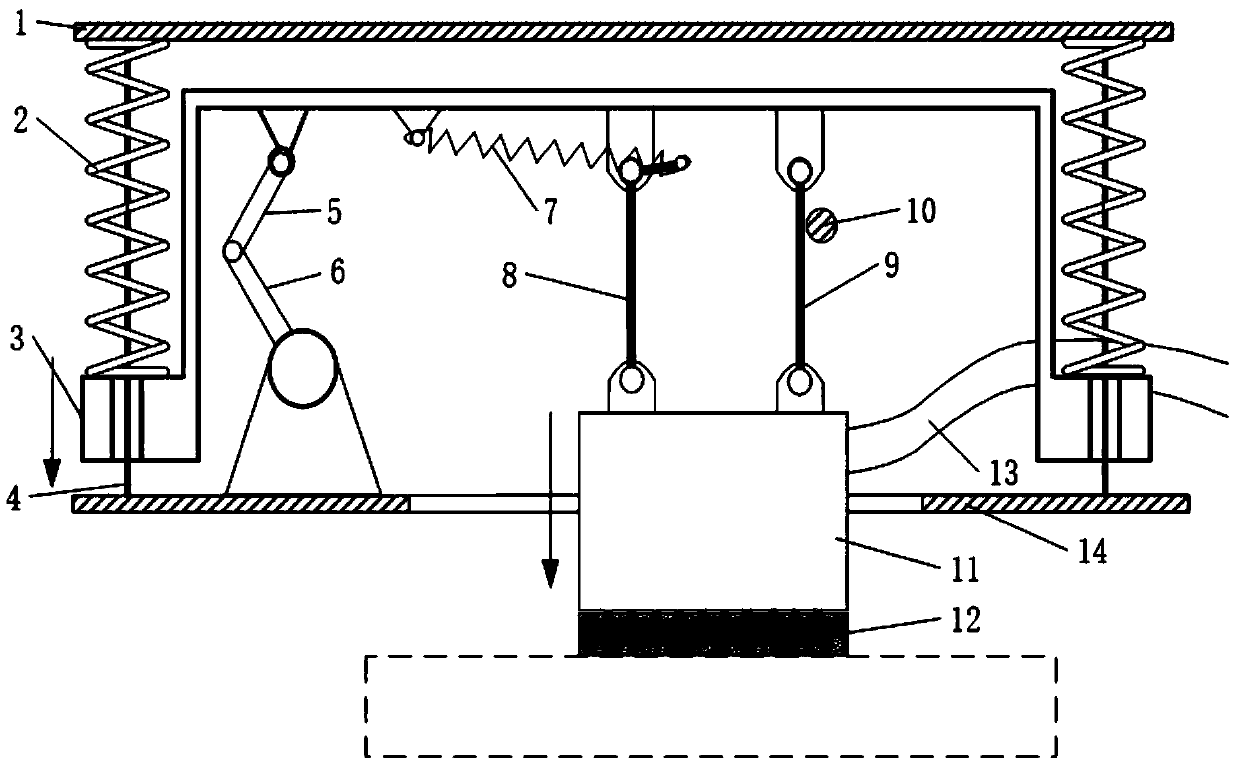

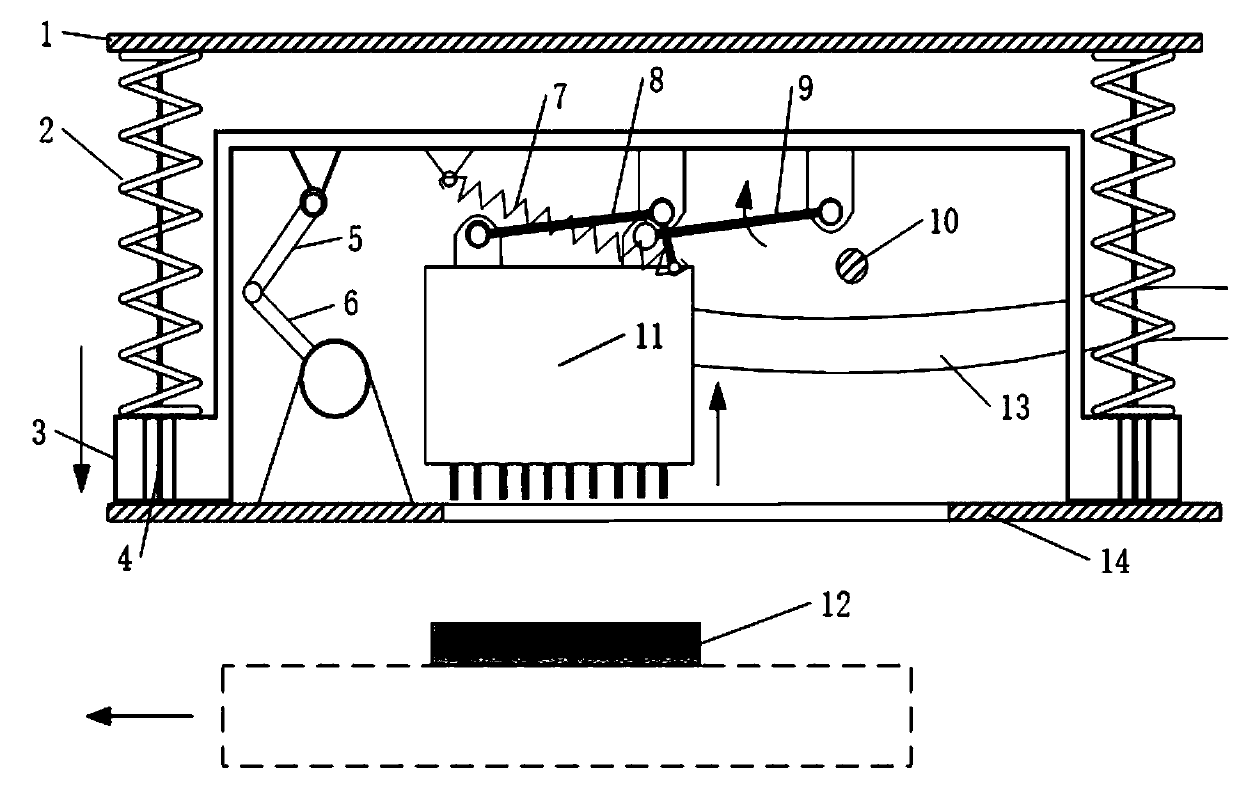

[0022] figure 1 It is a schematic diagram of the structure of the light aviation connector plug device in the vertical docking preparation state. The sliding seat 3 is driven upward by the joystick 6, and the sliding seat 3 drives the aviation plug 11 upward. At this time, the blocking effect of the positioning stop pin 10 is Make the aviation plug 11 directly above the aviation socket 12 to make room for the pins at the lower end of the aviation plug 11; release the joystick 6 and press the two compression springs 2 on the sliding seat 3 to make the aviation plug 11 downward The aviation plug 11 and the aviation socket 12 are vertically docked through self-guided fine-tuning. After the vertical docking is completed, the aviation plug 11 and the aviation socket 12 are compressed under the pressure of the two compress...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com