Metal belt type belleville spring with adjustable elastic force

A metal belt type, disc spring technology, used in springs, springs/shock absorbers, leaf springs, etc., can solve the problems of poor applicability and unadjustable spring force, achieve easy processing, expand the scope of application, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

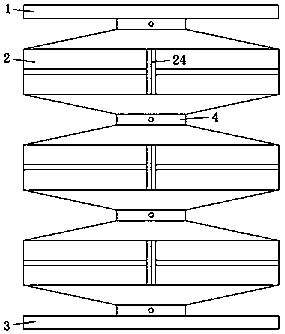

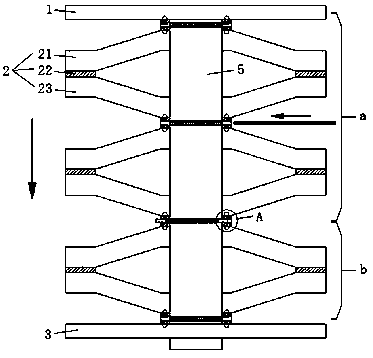

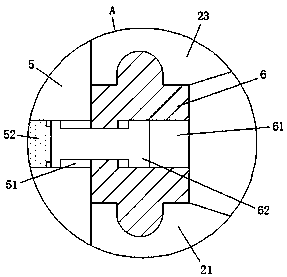

[0033] see Figure 2-Figure 4 As shown, and based on the above-mentioned disclosed structure, the elastic force adjustment assembly 4 includes a central shaft 5 and a first gasket 6, and forms a limiting member and a gasket member respectively, and the first gasket 6 is sleeved on the central shaft 5, and can be Relative sliding occurs, wherein a through hole 51 is opened at the position corresponding to the first gasket 6 on the central axis 5, and a damping limit rod 52 is embedded in the through hole 51; Mounting holes 61 are provided at positions corresponding to the ends, and push rods 62 are embedded in the two mounting holes 61 to realize the push-out and reset of the damping limit rod 52 .

[0034] In this embodiment, preferably, protrusions 53 are formed on the outer walls of both sides of the central shaft 5, and both protrusions 53 are formed to cooperate with the first gasket 6, and the connecting line of the two protrusions 53 is connected to the through hole. Th...

Embodiment 2

[0039] see Figure 5-Figure 8As shown, and based on the above-mentioned disclosed structure, wherein the elastic force adjustment assembly 4 includes a support member 7 and a second gasket 8, and respectively forms a limiting member and a gasket member, wherein the support member 7 includes symmetrically mounted on the second gasket 8 Inner rod 71 and overcoat 72, and one end of inner rod 71 is inserted in the overcoat 72, specifically as Figure 5 As shown, the interconnected inner rod 71 and the outer sleeve 72 are located inside the shrapnel assembly 2 to define the relative positions of the spring pieces in the shrapnel assembly 2, and the outer sleeve 72 is provided with a magnetic piston 76 for limiting the insertion depth of the inner rod 71; An air hole 81 is opened inside the second gasket 8 , one end of the air hole 81 is connected to the jacket 72 , and the other end of the air hole 81 is connected to an air valve 82 .

[0040] In this embodiment, preferably, the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com