A full-bore pipeline type desander

A full-bore, desander technology, applied to chemical instruments and methods, boreholes/well parts, separation methods, etc., can solve problems such as complicated installation and poor separation effect, and achieve high separation efficiency, convenient use, and separation effective way

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

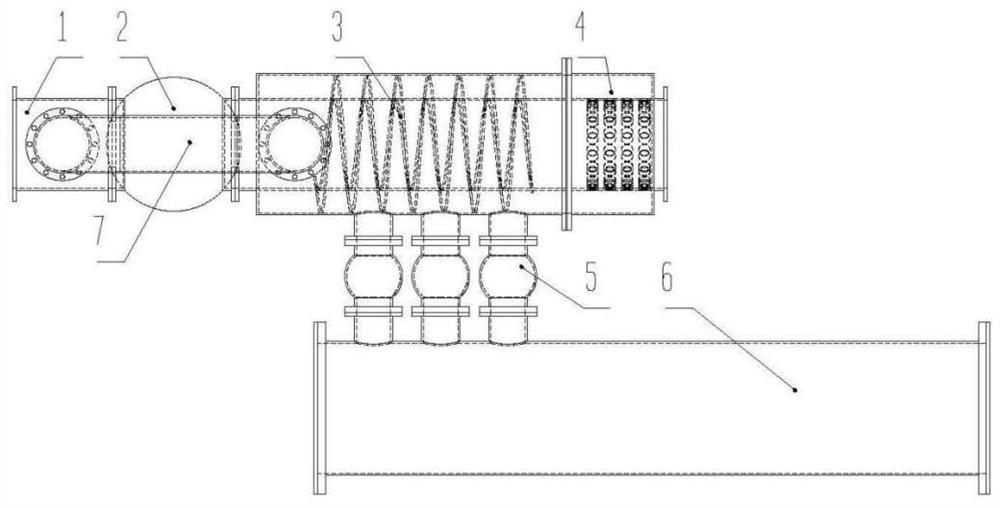

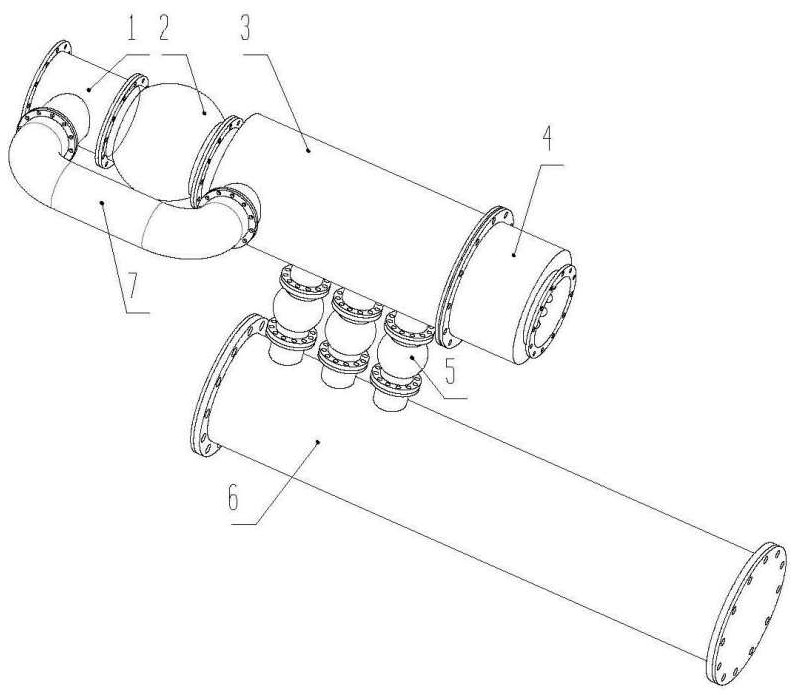

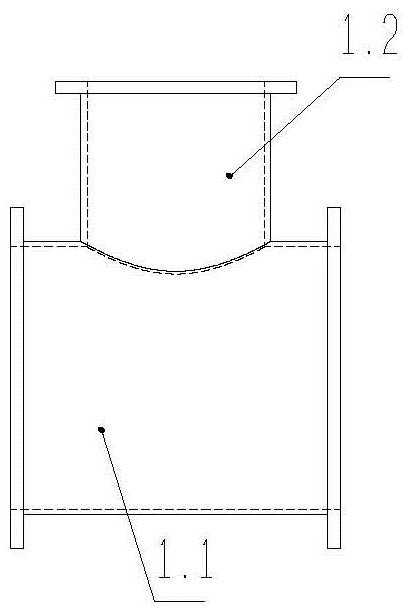

[0027] see Figure 1-8, a full-bore pipeline type desander of the present invention, comprising an inlet tee pipe 1, a full-bore pigging valve 2, a spiral sand removal section 3, a flow direction adjustment outlet 4, a bypass connecting pipe 7, and a full-bore ball valve 5 And the sand storage chamber 6, the inlet tee pipe 1 is composed of the tee main pipe 1.1 and the tee branch pipe 1.2, the spiral sand removal section 3 is a structure formed by nesting the inner cylinder 3.4 of the spiral sand removal section and the outer cylinder 3.3 of the spiral sand removal section , the inner cylinder 3.4 of the spiral desanding section is coaxially arranged with the outer cylinder 3.3 of the spiral desanding section, the inlet end of the inner cylinder 3.4 of the spiral desanding section is the main pipe inlet 3.1, and the end of the outer cylinder 3.3 of the spiral desanding section is the spiral desanding section The installation port of the inner cylinder 3.4, the other end is the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com