Novel composite drainage and seepage pipe with physical blockage resisting function

A composite drainage and drainage pipe technology, applied in the field of engineering drainage, can solve the problems of geotextile permeability coefficient drop, drainage pipe failure, blockage, etc., to reduce the risk of physical silting, increase drainage capacity, and ensure drainage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

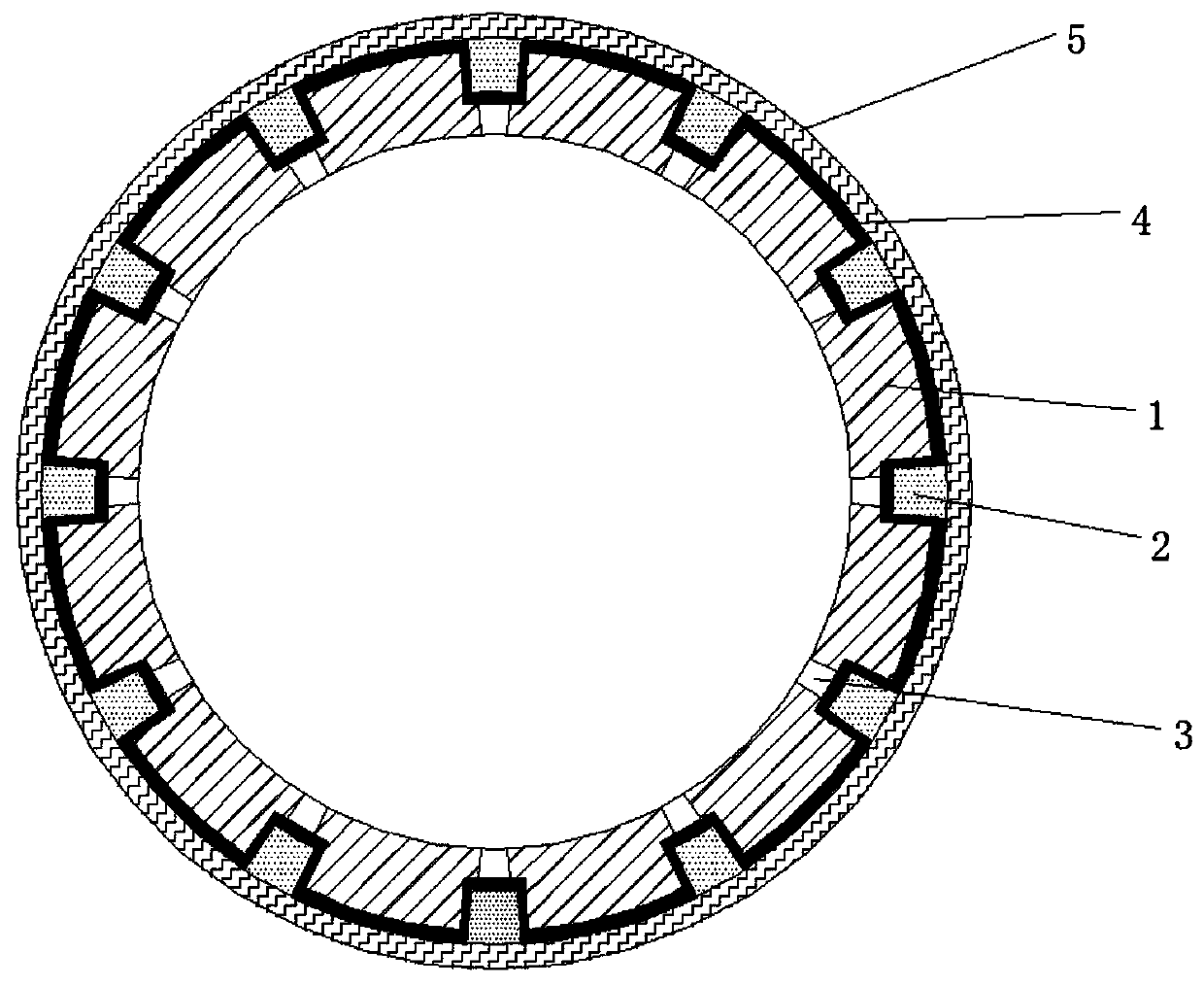

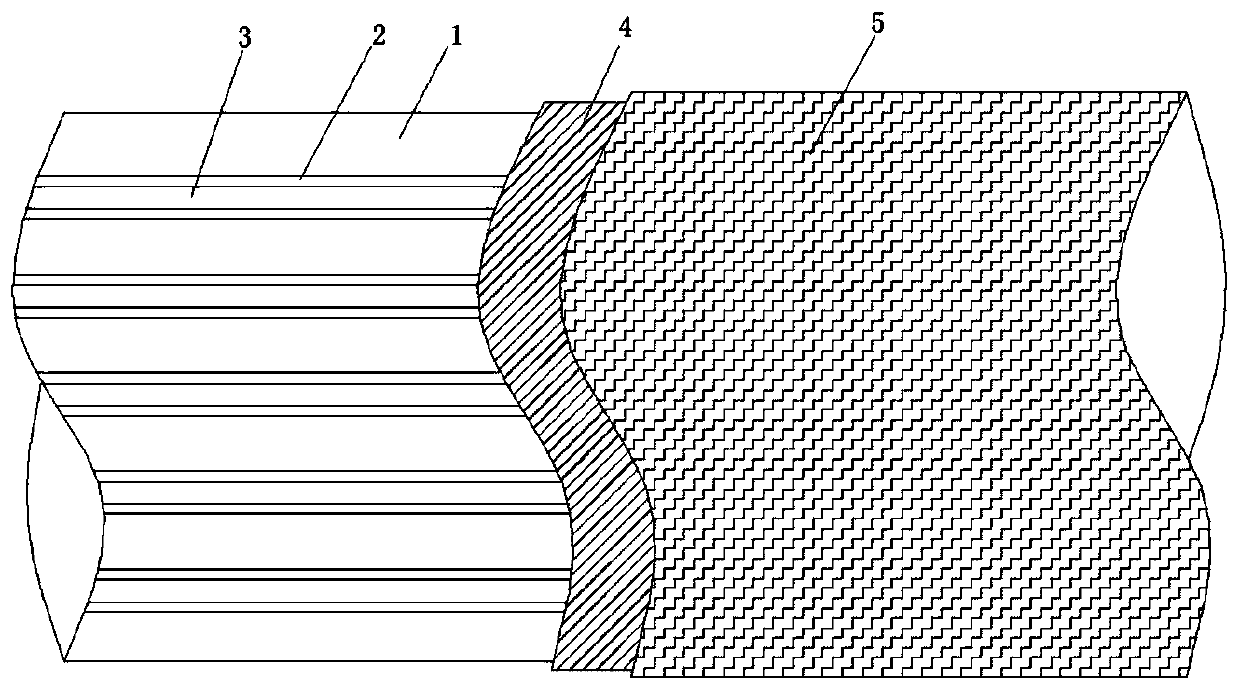

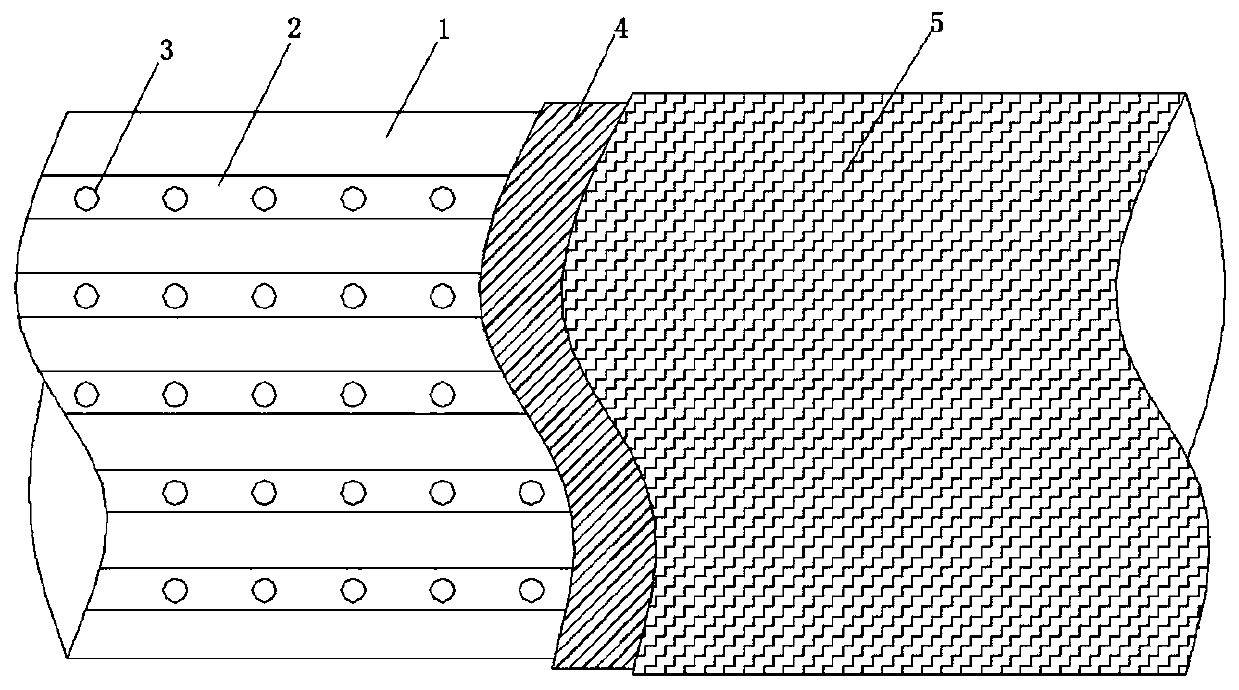

[0025] Such as Figure 1 to Figure 3 As shown, a novel composite drainage pipe of the present invention which is resistant to physical silting comprises a cylindrical drainage pipe body 1, the drainage pipe body 1 is a cylindrical U-PVC pipe, and the drainage pipe body 1 There are a number of seepage outer tanks 2 evenly distributed in a circular array around them. The bottom of the water seepage outer tanks 2 is provided with a water seepage structure 3 communicating with the inner wall of the seepage pipe body 1. The water seepage structure 3 is a continuous seepage inner tank or an intermittent seepage Inner hole, wherein the continuous seepage inner groove can increase the opening area of the drainage pipe 1 and enhance the water permeability, and its effect is better than that of the discontinuous seepage inner hole;

[0026] The outer wall of the see...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com