Anti-rollover device for forklift

An anti-rollover and forklift technology, applied in the direction of the lifting device, can solve the problems of large space and inconvenience of the anti-rollover device, increase the width of the vehicle body, etc., to reduce the space occupied by the device, increase stability, and have strong practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

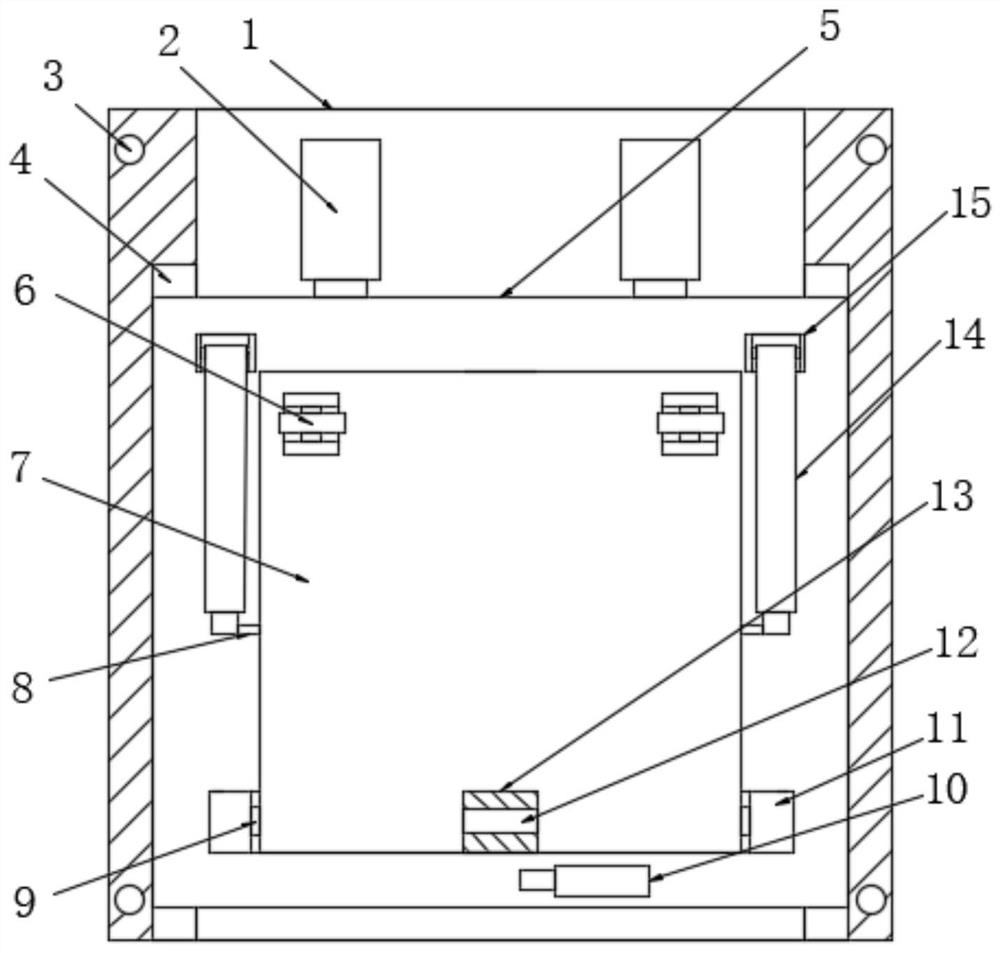

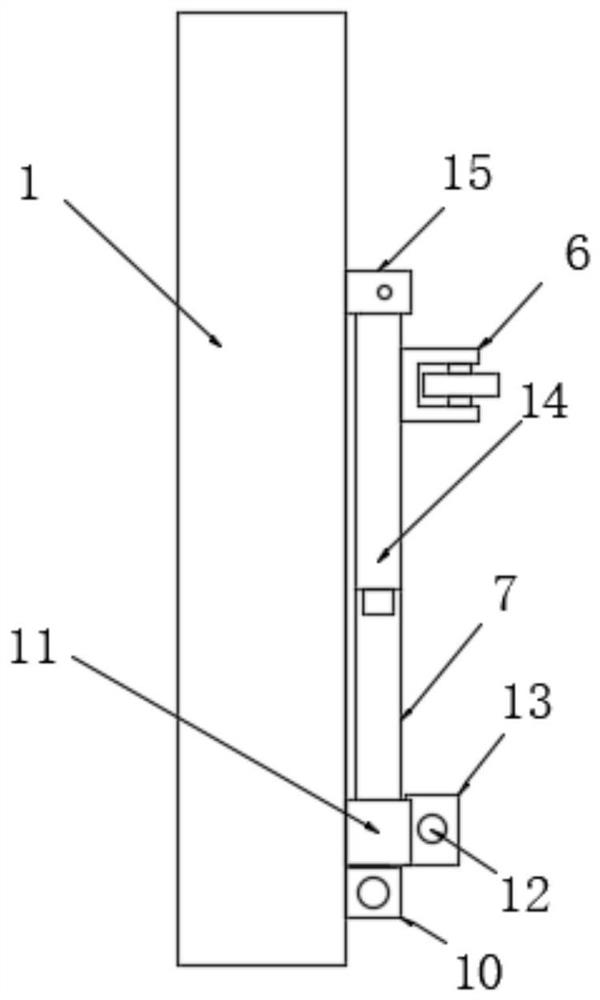

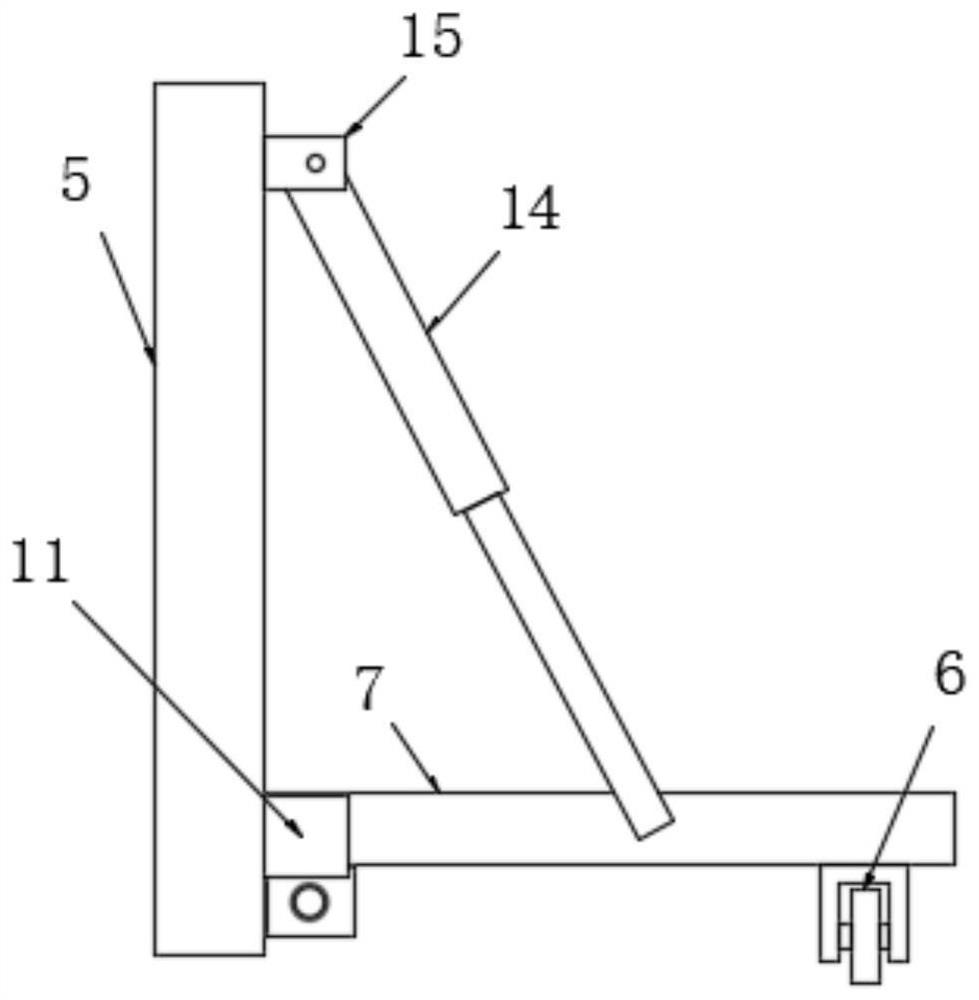

[0021]SeeFigure 1-3, An anti-rollover device for a forklift, comprising a U-shaped mounting plate 1, a guide chute 4 is symmetrically opened on the inner side of the U-shaped mounting plate 1, and a first hydraulic cylinder 2 is fixedly installed on the front surface of the U-shaped mounting plate 1 symmetrically , The lower ends of the two first hydraulic cylinders 2 are jointly fixedly connected with a movable plate 5 that matches the guide chute 4. The front surface of the movable plate 5 is fixedly installed with a U-shaped fixed plate 11 and two U-shaped hinge seats 15, U-shaped The fixed plate 11 is located directly below the U-shaped hinge seat 15, and the inner side of the U-shaped fixed plate 11 is fixedly installed with a fixed rod 9, the outer side of the fixed rod 9 is sleeved with a supporting plate 7, and the inner side of each U-shaped hinge seat 15 Both are rotatably connected with a second hydraulic cylinder 14, and the lower end of the second hydraulic cylinder 14 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com