Camshaft adjuster having stator and rotor with spring receptacle concentric thereto

A technology of camshaft adjuster and accommodating part, which is applied in the directions of machines/engines, engine components, mechanical equipment, etc., can solve the problems of small spring torque, pin breakage, long manufacturing time, etc., and achieves high production cost and eliminates wrong assembly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

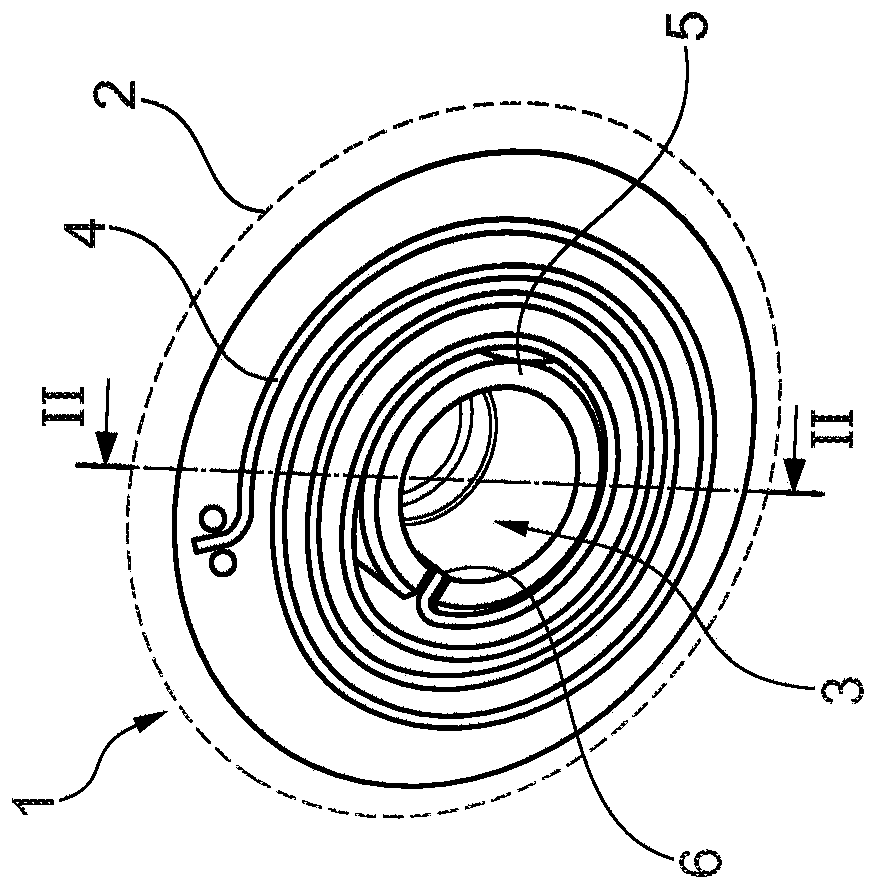

[0036] figure 1 The vane camshaft adjuster 1 is shown in FIG. It consists of a stator 2 and a rotor 3. A spring 4 is arranged between the stator 2 and the rotor 3. This spring is designed as a volute spring and is used to ensure that when there is no hydraulic pressure in the constructed hydraulic chamber, the stator 2 and the rotor 3 relatively occupy a predefined position.

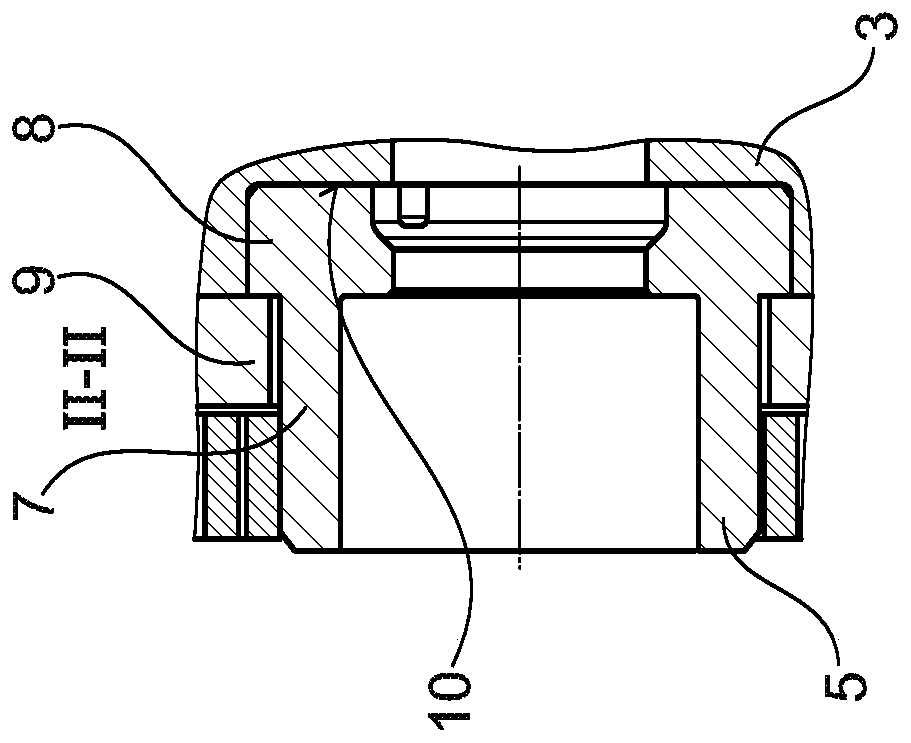

[0037] The camshaft adjuster 1 also has a spring receiving portion 5. The spring accommodating portion accommodates the radially inner end of the spring 4 via the slit 6. The section is shown along the line II-II, refer to figure 2 Explain it in more detail.

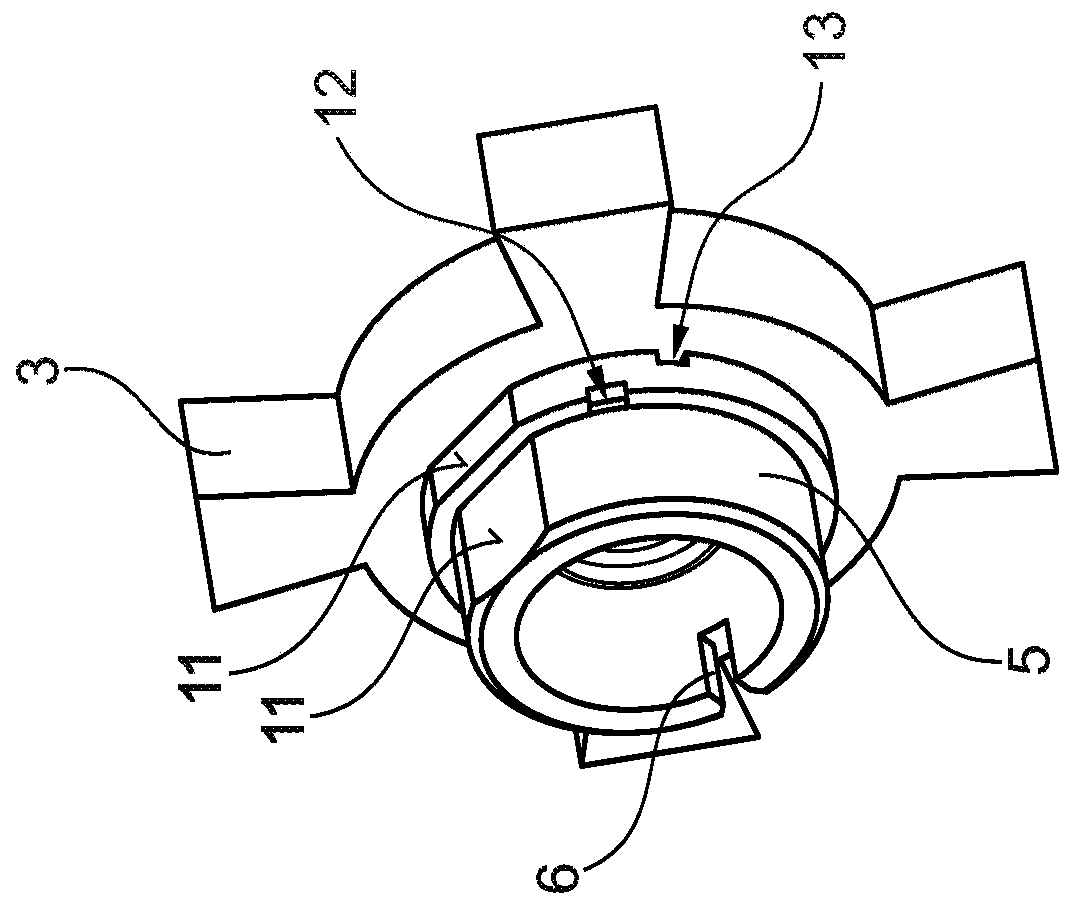

[0038] therefore, figure 2 It is shown that the spring receiving part 5 and the rotor 3 are designed as two independent components. The spring receptacle 5 is basically a sleeve-like component, which is designed concentrically with the rotor 3. The spring receiving part 5 is divided into a cylindrical section 7 and a ring section 8. The annular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com