Shell, manufacturing method thereof and electronic equipment

A shell and substrate technology, applied in the direction of electrical equipment shells/cabinets/drawers, electrical components, casings/cabinets/drawer components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

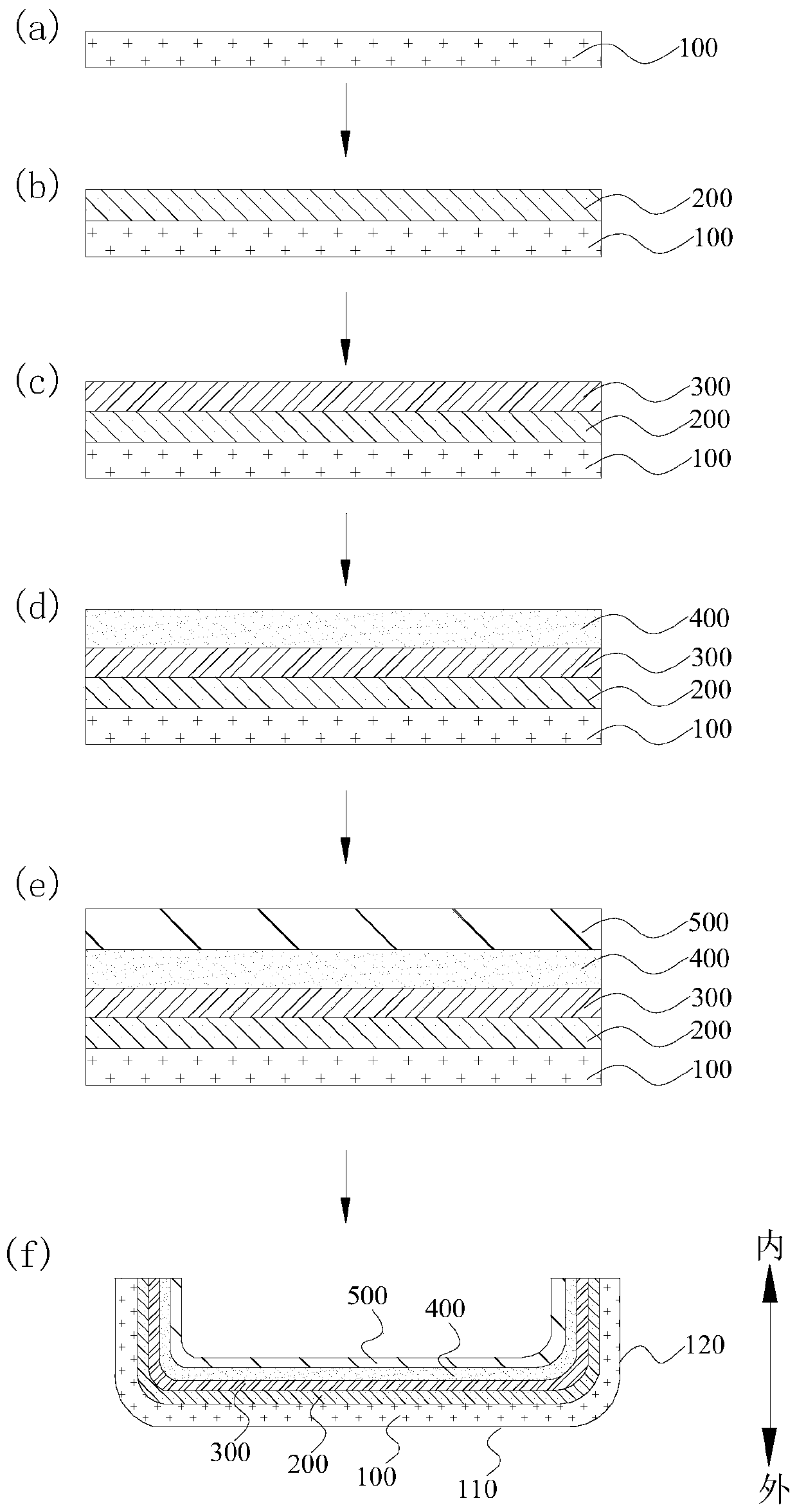

[0024] Embodiments of the application are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary, and are intended to explain the present application, and should not be construed as limiting the present application.

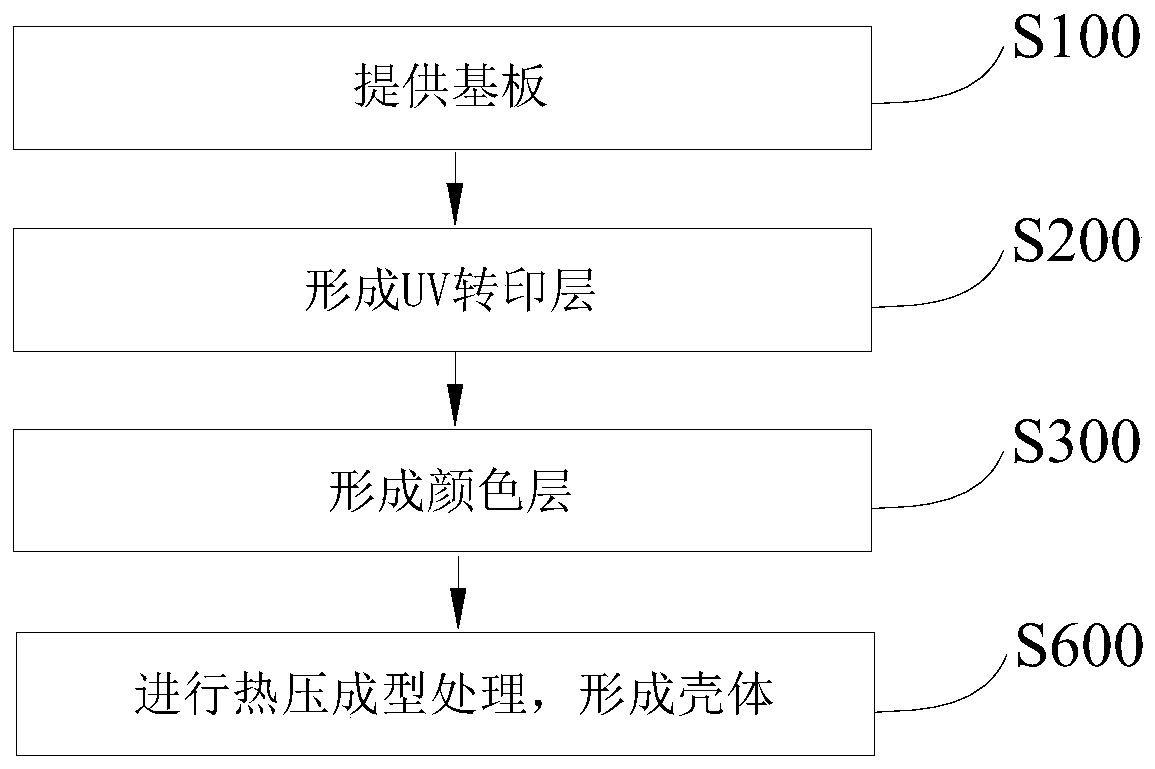

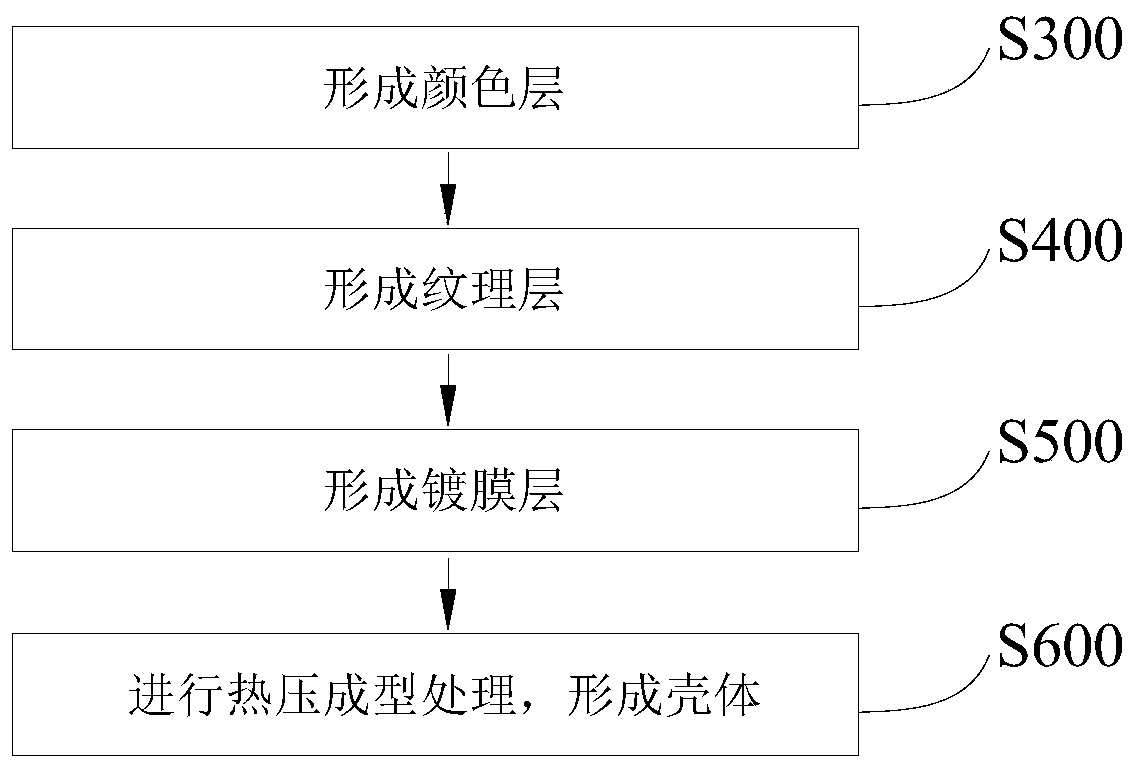

[0025] In one aspect of the present application, the present application proposes a method of making a casing. In the method, a UV transfer layer is first formed on the substrate, and then a color layer is formed on the UV transfer layer by inkjet printing, and then the substrate formed with the color layer is subjected to thermocompression molding treatment to form a shell with a bottom surface and a side wall. In this method, the UV transfer printing layer can improve the bonding force between the color layer and the substrate, and when the substrate is subsequently bent, the bonding force between the color layer and the substrate is strong, and the col...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com