Industrial Smart Camera

An intelligent camera and camera technology, applied in the field of cameras, can solve problems such as easy blocking of sight, inability to cover oil cover and cleaning, etc., to achieve the effect of convenient shooting, avoiding unclear shooting, and fulfilling the needs of fill light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

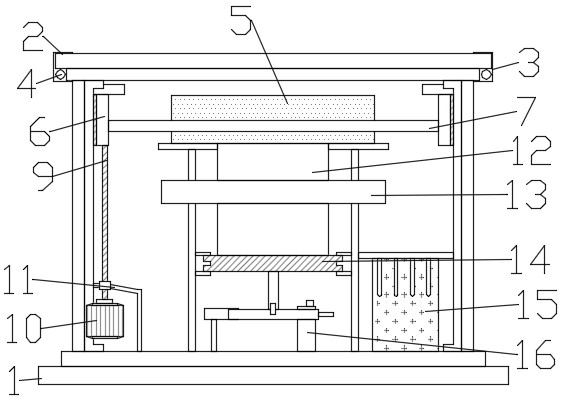

[0022] like figure 1 As shown, in the embodiment of the present invention, an industrial smart camera includes a housing 1, a glass cover 2 and a camera fixing cavity 5, the inside of the housing 1 is provided with a camera fixing cavity 5, and the camera fixing cavity 5 is installed in the camera fixing cavity On the mounting base 12, a glass cover 2 is set on the outside of the housing 1, and the housing 1 and the glass cover 2 are connected by a buckle 3, and a cleaning mechanism for cleaning the inner wall of the housing 1 is also provided in the housing 1;

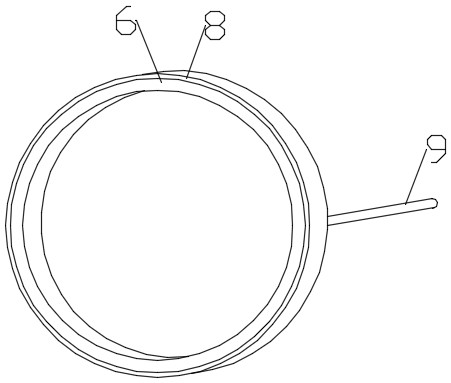

[0023] like figure 2 As shown, the cleaning mechanism includes a cleaning ring 6, a cleaning layer 8 and a screw rod 9. The cleaning ring 6 is covered with a cleaning layer 8. The cleaning layer 8 is made of a hard brush material, and the inside of the cleaning layer 8 is provided with an internal threaded hole. , the internal threaded hole is threadedly connected with a screw 9, and the inside of the cleaning ring ...

Embodiment 2

[0028] like figure 1 As shown, in the embodiment of the present invention, an industrial smart camera includes a housing 1, a glass cover 2 and a camera fixing cavity 5, the inside of the housing 1 is provided with a camera fixing cavity 5, and the camera fixing cavity 5 is installed in the camera fixing cavity On the mounting base 12, a glass cover 2 is set on the outside of the housing 1, and the housing 1 and the glass cover 2 are connected by a buckle 3, and a cleaning mechanism for cleaning the inner wall of the housing 1 is also provided in the housing 1;

[0029] like figure 2 As shown, the cleaning mechanism includes a cleaning ring 6, a cleaning layer 8 and a screw rod 9. The cleaning ring 6 is covered with a cleaning layer 8. The cleaning layer 8 is made of a hard brush material, and the inside of the cleaning layer 8 is provided with an internal threaded hole. , the internal threaded hole is threadedly connected with a screw 9, and the inside of the cleaning ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com