Shock absorber bearing load simulation test device

A shock absorber bearing and load simulation technology, applied in the direction of mechanical bearing testing, etc., can solve the problems of inaccurate detection and affecting the flatness measurement of shock absorber bearings, etc., achieve high efficiency and use effect, facilitate implementation, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

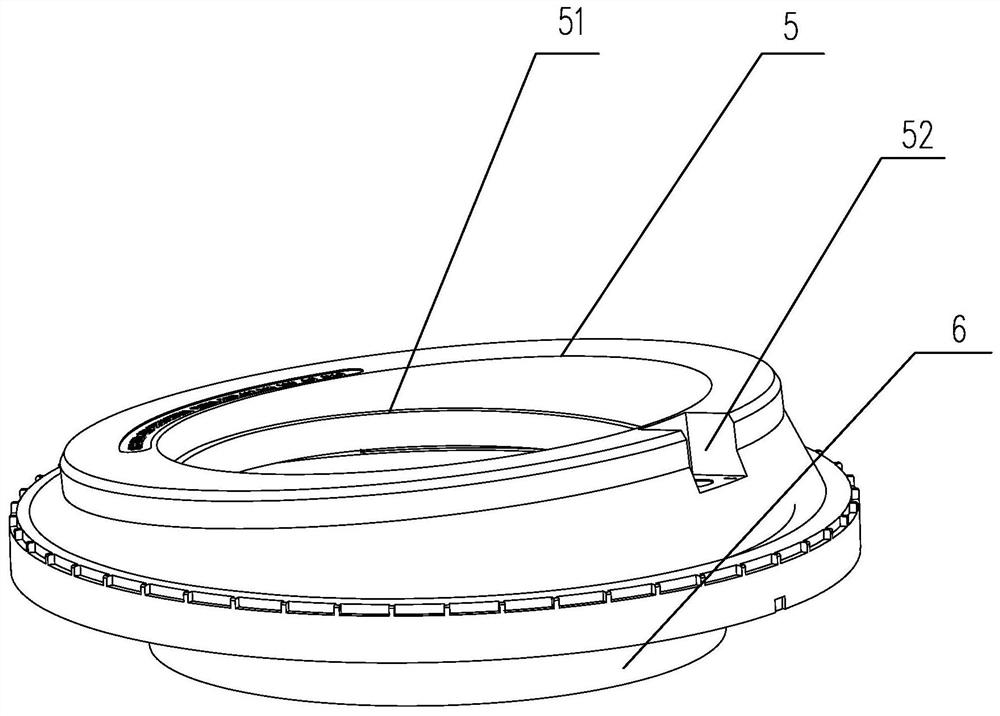

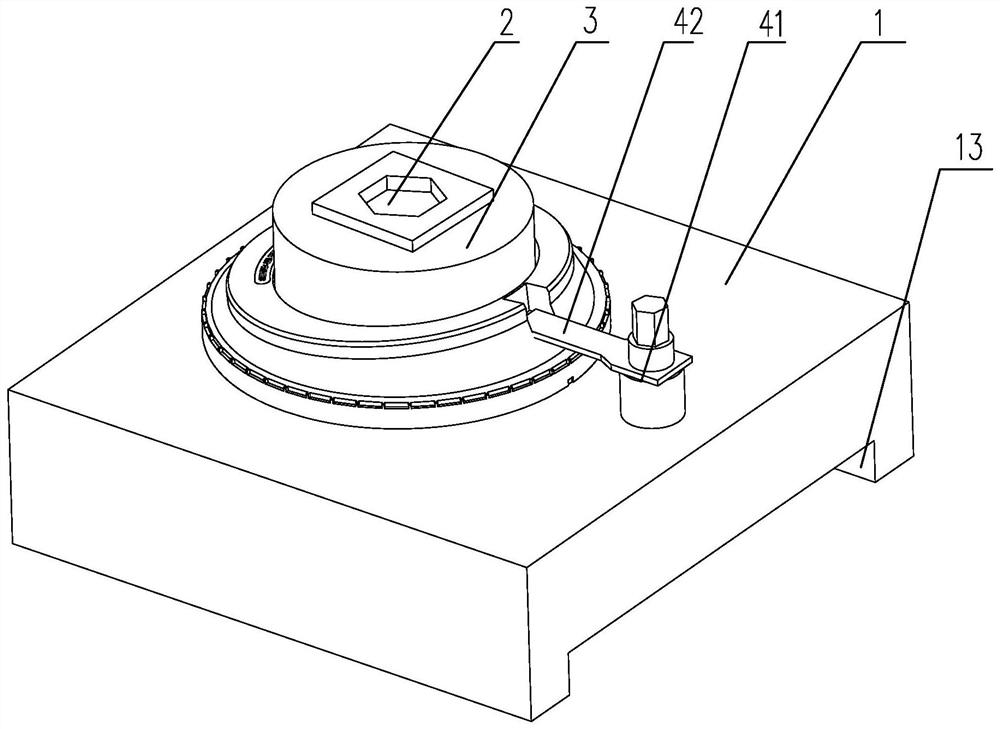

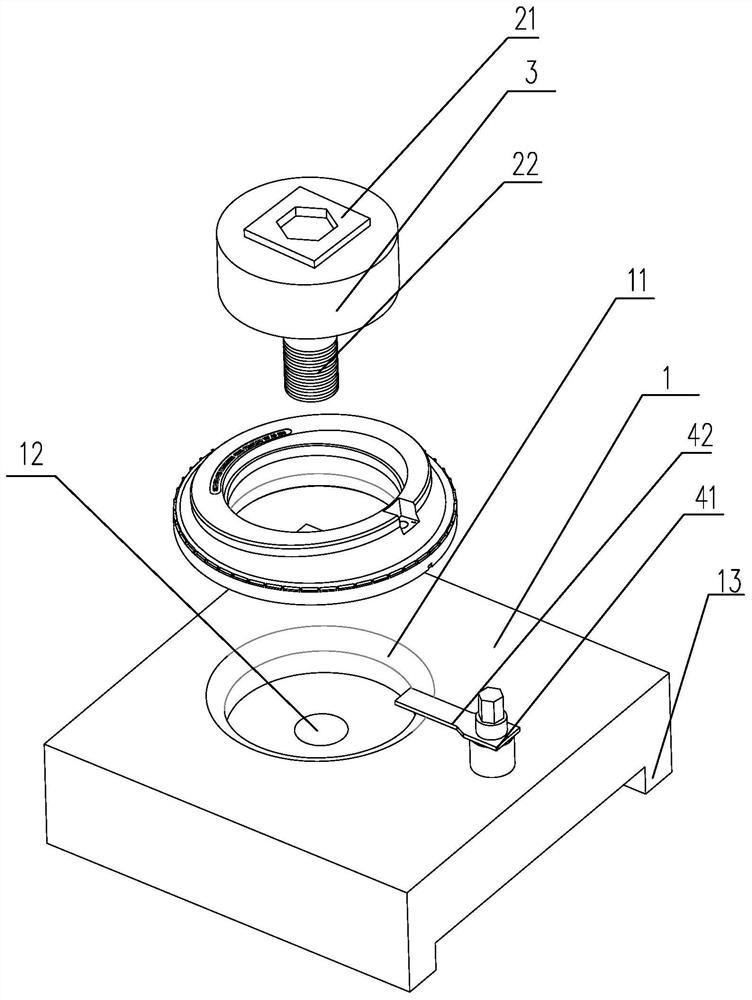

[0015] Depend on figure 2 with image 3 Disclosed is a shock absorber bearing load simulation test device, comprising a base 1, the base 1 is provided with a mounting groove 11 for mounting a bearing to be tested, the bottom surface of the mounting groove 11 is provided with a positioning hole 12, and the positioning hole 12 The upper thread is matched with a positioning screw 2, and the positioning screw 2 is provided with a positioning plate 3 along the circumference. The end is connected with a torque meter, and the base 1 is provided with a positioning piece on the side of the installation groove 11 for limiting the rotation of the bearing to be tested. The beneficial effect of this setting is: adopt the above scheme, set the steps passing through the inner side of the outer ring of the bearing in this way, use the structural characteristics of the bearing to be tested, and use the torque calculation to convert the load on the slope in actual use to that of the shock abs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com