Submerged floating tunnel shore connecting system, submerged floating tunnel, and submerged floating tunnel construction method

A technology for suspended tunnels and design methods, applied in pontoon bridges, artificial islands, water conservancy projects, etc., can solve problems such as affecting the structural safety, driving safety, passenger comfort experience, affecting the safety of suspended tunnels, and transmitting resonance risks. The effect of designing redundancy, improving safety and reliability, and reducing maintenance difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0107] Embodiment 1 provides a method for designing a floating tunnel, in which axial tension is applied to both ends of the tube body 1 of the floating tunnel. Of course, it is also possible to apply an axial pulling force along one end of the tube body 1 of the suspension tunnel, while the other end only provides a reaction force.

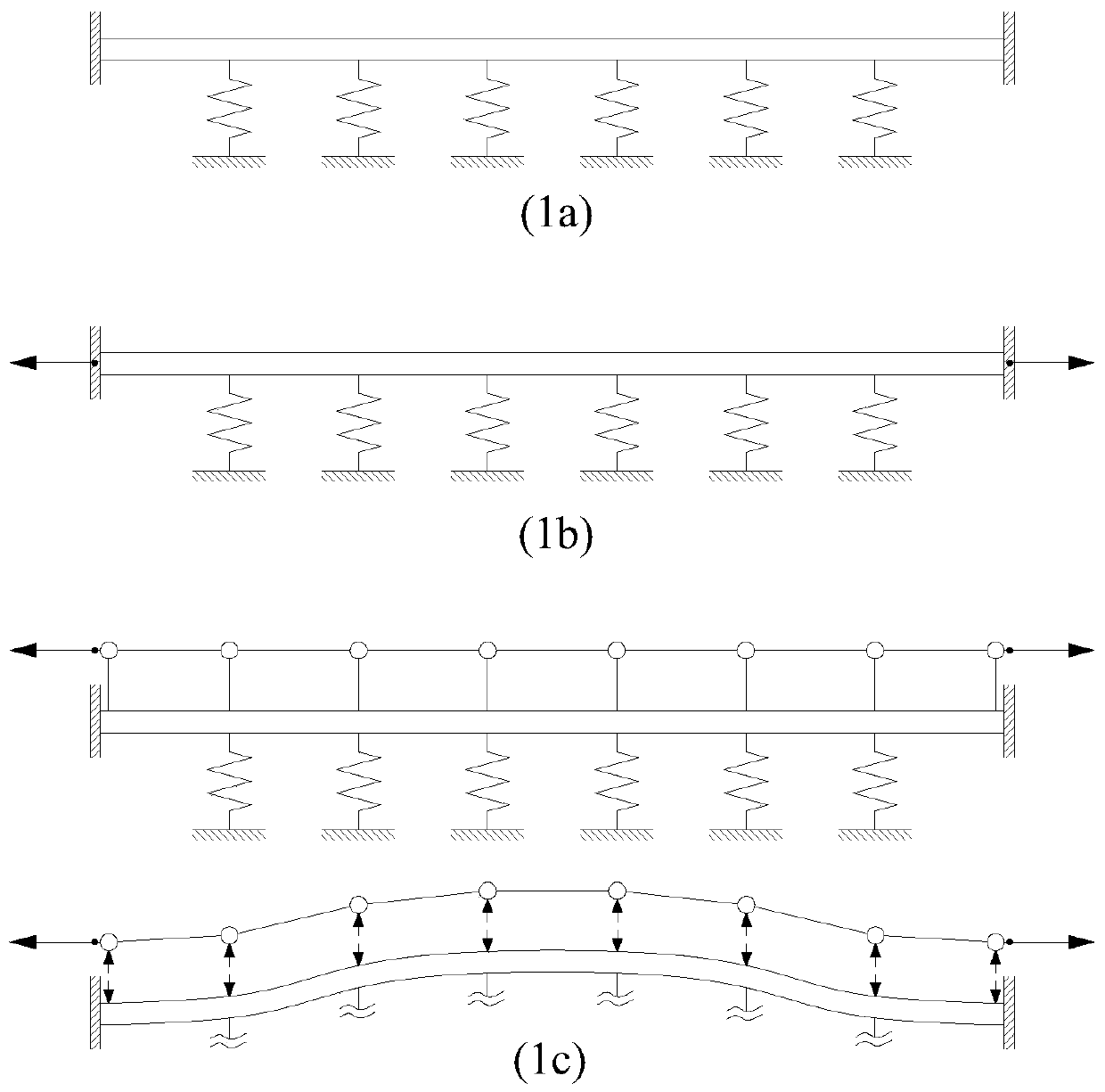

[0108] Through the force analysis of the suspension tunnel body 1, the change of front and rear force occurs when the both ends of the suspension tunnel body 1 are subjected to axial tension. Such as figure 1 As shown in a-1c, the structural stiffness system of the floating tunnel in the prior art is composed of the stiffness contributions of the pipe body 1 and the anchorage system (such as figure 1 As shown in a), the anchoring system can be a cable 22, a buoy, or both. In this embodiment, by applying the axial tension of the pipe body 1 ( figure 1 shown in b), which additionally increases the stiffness (see the principle figure 1 c), there...

Embodiment 2

[0129] Such as Figure 3-5 As shown, this embodiment 2 also provides a floating tunnel landing system, including a joint section 12 located at the end of the floating tunnel, the joint section 12 can move axially along the pipe body, and the joint section 12 is provided with a tension device 2. The tension device 2 is used to apply axial tension to the joint section 12 .

[0130] Wherein, the above-mentioned joint section 12 passes through the shore foundation 101, and is not fixed or hingedly connected to the shore foundation 101. The joint section 12 can move along the axial direction of the pipe body 1 relative to the shore foundation 101, Avoiding the reaction force provided by the shore foundation 101 to the joint section 12 when the joint section 12 is pulled by the tension device 2 to reduce the influence of the horizontal stiffness of the tension device lifting the pipe body 1 .

[0131]The tension device 2 is connected to the shore foundation 101, and by directly con...

Embodiment 3

[0139] Such as Figure 3-5 As shown, this embodiment 3 provides a suspension tunnel, including a pipe body 1 and a hollow cavity 18, the pipe body 1 includes a suspension section 11, and the two ends of the suspension section 11 are respectively connected with Landing system: the joint sections 12 pass through the shore foundation 101 , and the two joint sections 12 are provided with tension devices 2 , and the tension devices 2 are used to apply axial tension to the corresponding joint sections 12 .

[0140] Wherein, the magnitudes of the above two axial pulling forces are the same, and the directions of the axial pulling forces are opposite. The suspension section 11 and the two joint sections 12 all include a steel plate layer 13 and a reinforced concrete layer 14 located in the steel plate layer 13, all the steel plate layers 13 are integral structural parts, and all the reinforced concrete layers 14 are integral structures pieces. The cross-sectional shape of the pipe b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com