Method for synergetic drying pyrolysis of sludge and medicine residues

A technology of medicine dregs and sludge, which is applied in chemical instruments and methods, sludge treatment, biological sludge treatment, etc., can solve the problem of increasing treatment costs, being easily affected by environmental changes, and prolonging the synergistic treatment process of sludge and medicine dregs route and other issues to achieve the effect of high energy saving and environmental protection benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

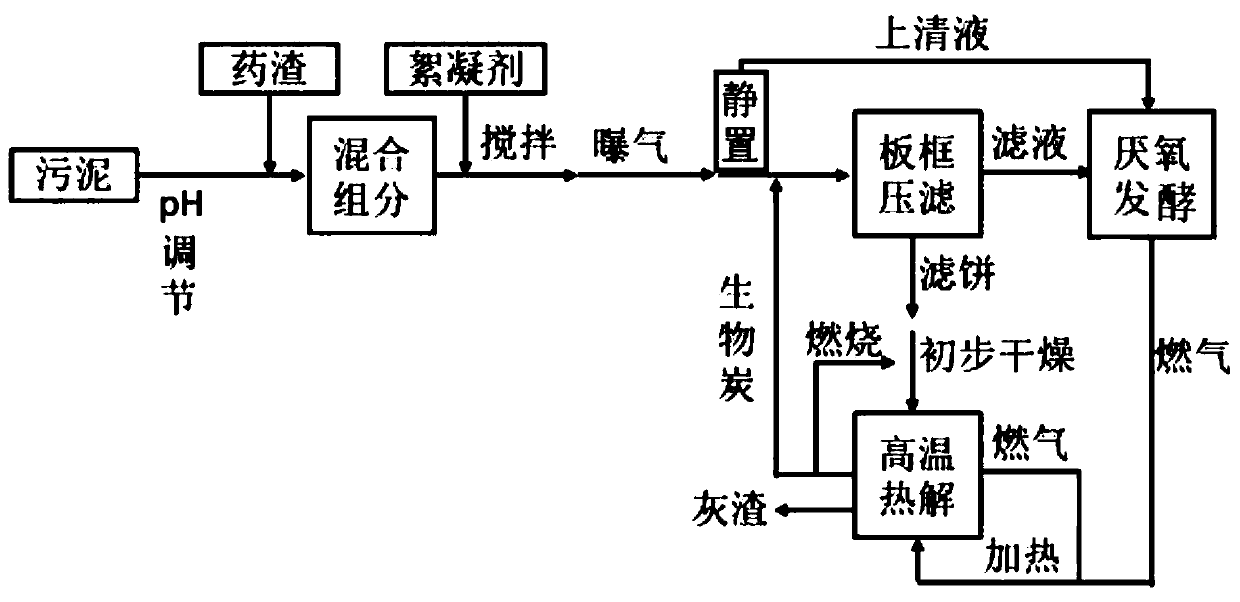

[0026] Combine below figure 1 Be explained. figure 1 It is a process flow diagram of a method for synergistic drying and pyrolysis of sludge and medicinal residues.

[0027] In this embodiment, the drying treatment of sludge and medicinal residues is realized through the synergistic drying and pyrolysis of sludge and medicinal residues, which is divided into four steps: component compounding, specific resistance adjustment, cooperative dehydration, and high-temperature pyrolysis.

[0028] Component compounding: According to the characteristics of the water content, sand content, and organic matter content of the municipal sludge, the pH of the sludge is adjusted to 6.5-7.5 to provide the best conditions for the enzymatic reaction of the enzyme contained in the dregs. The medicinal dregs whose rate and composition are basically stable are added to the sludge according to a certain proportion and fully mixed, mechanically stirred for 2-3 hours, and the residual bactericidal fun...

Embodiment 2

[0033] According to the method of synergistic drying and pyrolysis treatment of sludge and medicinal residues provided in the examples, take 4kg of sludge from a sewage treatment plant, add NaOH and stir evenly, adjust its pH to about 7.0, and then add 1kg of Coptis chinensis to the sludge The medicinal dregs were mixed and stirred for 2 hours, and the trace bactericidal components contained in the coptis rhizome dregs were used to complete the preliminary killing of microorganisms in the sludge and promote the release of intracellular fluid. After the stirring is completed, add 180g of polyferric sulfate to the mixed components and continue to stir evenly and continue to aerate for 2 hours. Add 100g of carbon powder to the mixture of mud and medicinal residues and continue to stir evenly to absorb a small amount of residual polysaccharides, proteins and other substances in the components that may affect the specific resistance of the mixed components.

[0034] The mixed compo...

Embodiment 3

[0038]Take 3kg of sludge from a sewage treatment plant, add NaOH and stir evenly, adjust its pH to about 7.0, then add 2kg of Coptis chinensis dregs to the sludge and mix and stir for 2 hours. After the stirring is completed, add 180g of polyferric sulfate to the sludge, continue to stir evenly and continue to aerate for 2 hours. Add 100g of carbon powder to the mixture and continue to stir evenly to absorb a small amount of residual polysaccharides, proteins and other substances that may affect the specific resistance of the sludge.

[0039] The sludge that has completed the above treatment steps is introduced into the plate and frame constant pressure filtration experimental device for plate and frame filter press operation. The filtrate obtained by the plate and frame filter press operation is transferred to a conditioning tank, mixed with the supernatant obtained in the standing step, and after conditioning, is transferred to an anaerobic fermentation tank for anaerobic fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com