Preparation method of acetylated sodium hyaluronate

A technology of sodium hyaluronate and hyaluronic acid, applied in chemical instruments and methods, preparation of sugar derivatives, organic chemistry, etc., can solve the problems of high preparation cost, complicated catalyst, difficult purification treatment, etc., and achieve simple steps and high reaction efficiency Gentle, simple separation and purification steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

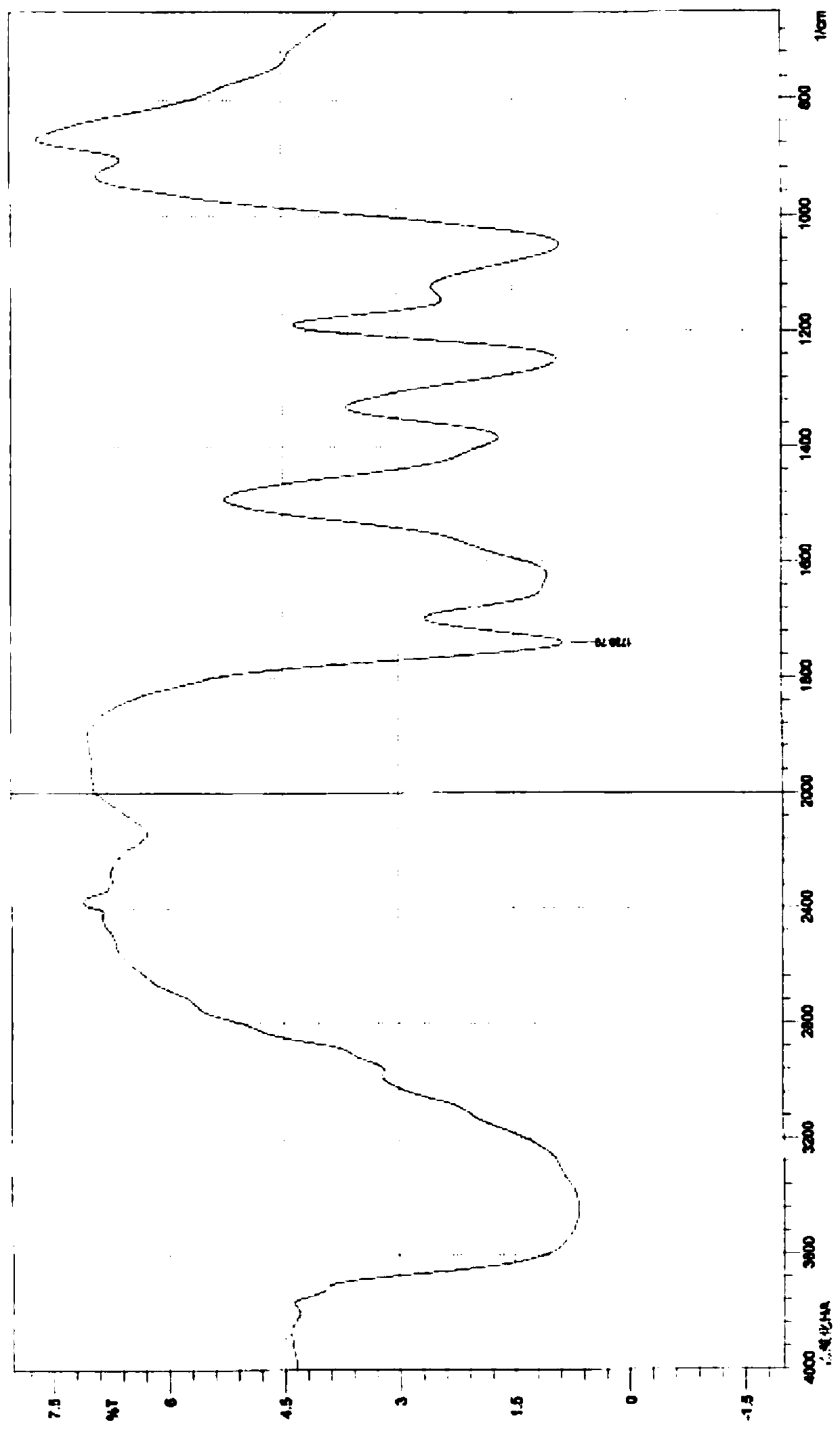

Image

Examples

Embodiment 1

[0032] Example 1 Preparation of acetylated sodium hyaluronate

[0033] (1) Dehydrate DMF with molecular sieves to keep the water content below 0.02%. Add 100mL of acetyl chloride into an equal volume of DMF, use nitrogen for degassing protection treatment, and refrigerate at 0-8°C for 30min for later use;

[0034] (2) Under nitrogen protection, weigh 50.00g of HA with a molecular weight of 800KDa in a 1000mL reaction bottle, add it into anhydrous 400mL DMF and stir to form a uniform suspension, then add the acetyl chloride-DMF solution in (1) dropwise Add it dropwise to HA for 30 minutes. After the dropwise addition, raise the temperature to 60° C. and react for 8 hours to obtain a transparent and viscous solution. Then cool down to 30°C for 16 hours;

[0035] (3) Slowly add 2400mL of distilled water under stirring to produce a fibrous or flocculent white or off-white solid, and wash the solid with distilled water until no foam occurs;

[0036] (4) Dissolve it with a sodium...

Embodiment 2

[0038] Example 2 Preparation of acetylated sodium hyaluronate

[0039] (1) Dehydrate DMF with molecular sieves to keep the water content below 0.02%. Add 80mL of acetyl chloride to an equal volume of DMF, use nitrogen for degassing protection treatment, and refrigerate at 0-8°C for 30min for later use;

[0040] (2) Under nitrogen protection, weigh 50g of HA with a molecular weight of 1000KDa in a 1000mL reaction bottle, add it into anhydrous 400mL DMF and stir to form a uniform suspension, then add the acetyl chloride-DMF solution in (1) dropwise to HA was added dropwise for 25 minutes, and after the dropwise addition was completed, the temperature was raised to 75° C. for 8 hours to obtain a transparent and viscous solution. Then cool down to 25°C for 16 hours;

[0041] (3) Slowly add 2200mL of distilled water under stirring to produce a fibrous or flocculent white or off-white solid, and wash the solid with distilled water until no foam occurs;

[0042] (4) Dissolve it wi...

Embodiment 3

[0044] Example 3 Preparation of acetylated sodium hyaluronate

[0045] (1) Dehydrate DMF with molecular sieves to keep the water content below 0.02%. Add 120mL of acetyl chloride into an equal volume of DMF, use nitrogen for degassing protection treatment, and refrigerate at 0-8°C for 30min for later use;

[0046] (2) Under nitrogen protection, weigh 50g of HA with a molecular weight of 1500KDa in a 1000mL reaction bottle, add it into anhydrous 400mL DMF and stir to form a uniform suspension, then add the acetyl chloride-DMF solution in (1) dropwise to In HA, add dropwise for 30 minutes. After the dropwise addition, raise the temperature to 65°C and react for 8 hours to obtain a transparent and viscous solution, then cool down to 40°C and react for 16 hours;

[0047] (3) Slowly add 2600mL of distilled water under stirring to produce a fibrous or flocculent white or off-white solid, and wash the solid with distilled water until no foam occurs;

[0048] (4) Dissolve it with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com