Burn-free brick and its preparation method

A technology that does not burn bricks and incinerates ash and slag, which is applied in the fields of environmental protection and circular economy, and can solve the problems of difficult disposal of incineration fly ash.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

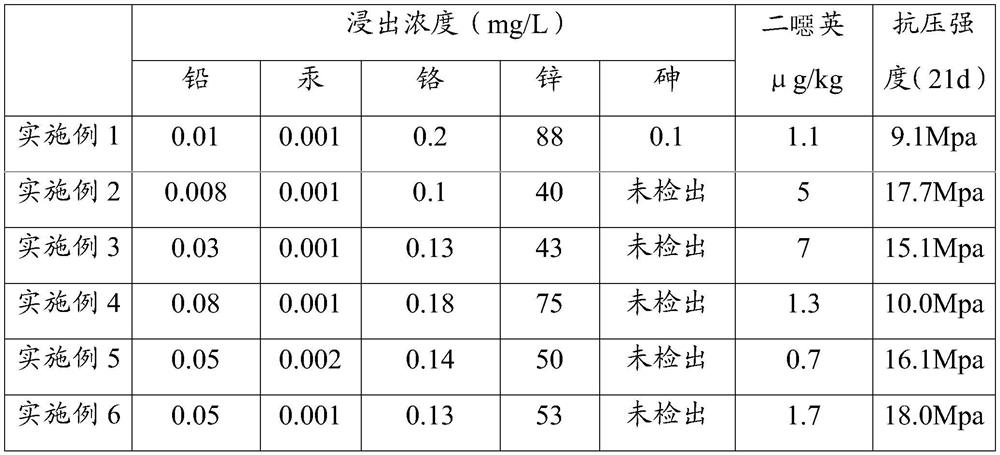

Examples

Embodiment 1

[0030] This embodiment is to comprehensively utilize domestic garbage incineration residues to make sidewalk paving bricks.

[0031] A process for making non-burning bricks by using domestic waste incineration fly ash and industrial waste slag, the process includes the following steps:

[0032] (1) Place domestic waste incineration fly ash, alkaline substances, industrial waste residue, water glass and solvent in their respective feeding systems;

[0033] The alkaline substances include waste alkali slag, waste alkali liquor and red mud with pH>12, and the ratio of parts by weight is 1:7:2; the industrial waste residue is waste calcium carbonate and waste sand of castings, and the parts by weight are The ratio is 3:1; the solvent is the landfill leachate concentrate;

[0034] The mass percentages of the domestic waste incineration fly ash, alkaline substances, industrial waste residue, water glass and solvent are respectively 40%, 15%, and 15% of the total mass of domestic wa...

Embodiment 2

[0038] This embodiment is to comprehensively utilize fly ash to make building bricks.

[0039] A process for making non-burning bricks by using domestic waste incineration fly ash and industrial waste slag, the process includes the following steps:

[0040] (1) Household waste incineration fly ash, alkaline substances, industrial waste residues, water glass and solvents are placed in their respective feeding systems;

[0041] The alkaline substances include waste sodium hydroxide and ground red mud, and the ratio of parts by weight is 7:3; the industrial waste is waste calcium carbonate and iron ore tailings, and the ratio of parts by weight is 5:1 ; The solvent is clear water, landfill leachate and landfill leachate concentrate, and its weight and number ratio is 80:5:3;

[0042]The mass percentages of the domestic waste incineration fly ash, alkaline substances, industrial waste residue, water glass and solvent are respectively 45%, 10%, and 10% of the total mass of domesti...

Embodiment 3

[0047] A process for making non-burning bricks by using domestic waste incineration fly ash and industrial waste slag, the process includes the following steps:

[0048] (1) The mixture of domestic waste incineration fly ash and residue, alkaline substances, industrial waste residue, water glass and solvent are placed in their respective feeding systems; the domestic waste incineration residue is fly ash and incineration ash, and The ratio of parts by weight of garbage fly ash, fly ash and incineration ash is 8:3:2; the waste alkaline substances include waste sodium hydroxide and waste lye with pH>12, and the ratio of parts by weight is 15 : 10; the industrial waste slag is waste calcium carbonate, casting waste sand and iron ore tailings slag, and its weight and number ratio is 4:2:1; the solvent is the landfill leachate concentrate;

[0049] The mass percentages of the mixture of domestic waste incineration fly ash and residue, alkaline substances, industrial waste residue, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com