A portable packer

A portable, machine-based technology, applied in the field of balers, can solve the problems of difficulty in large-scale promotion and application, cumbersome operation steps, and high integration, and achieve the effects of improving work independence, improving operation efficiency, and simplifying internal structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

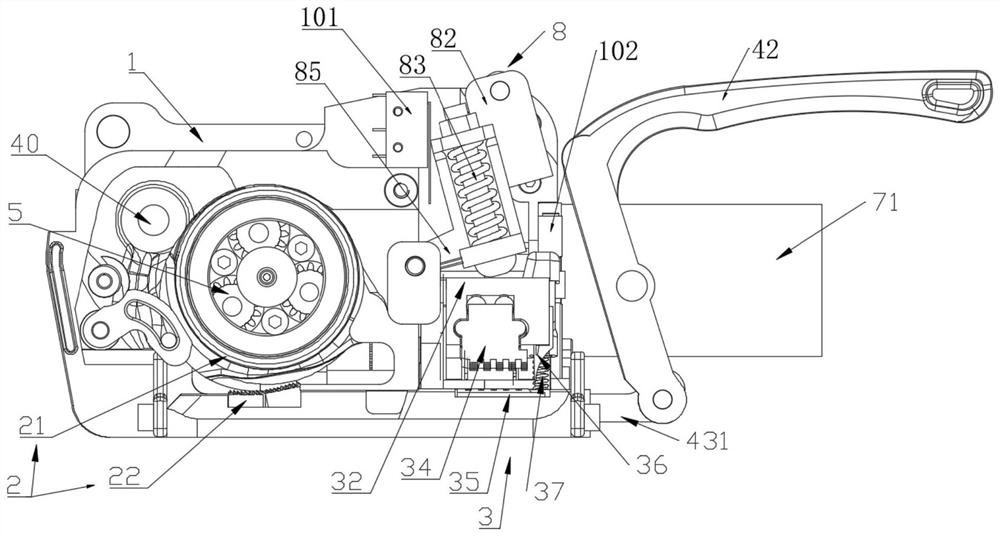

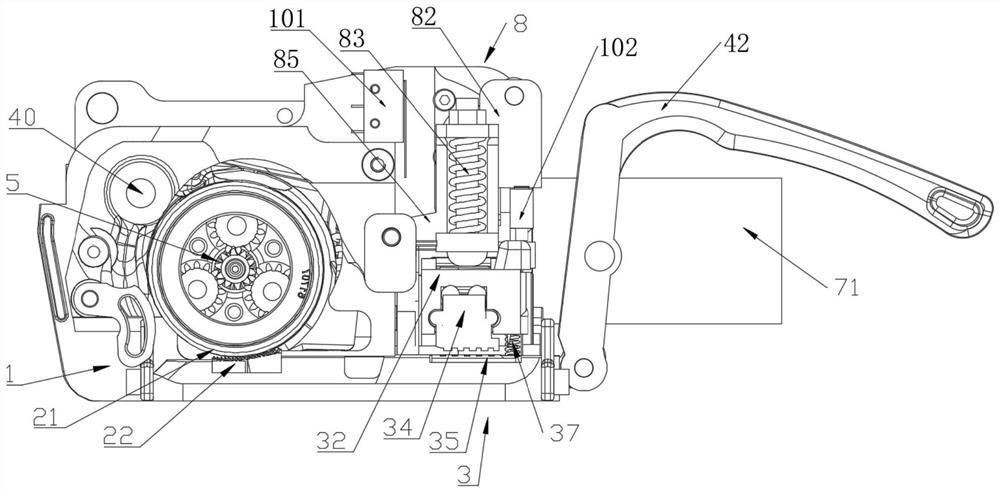

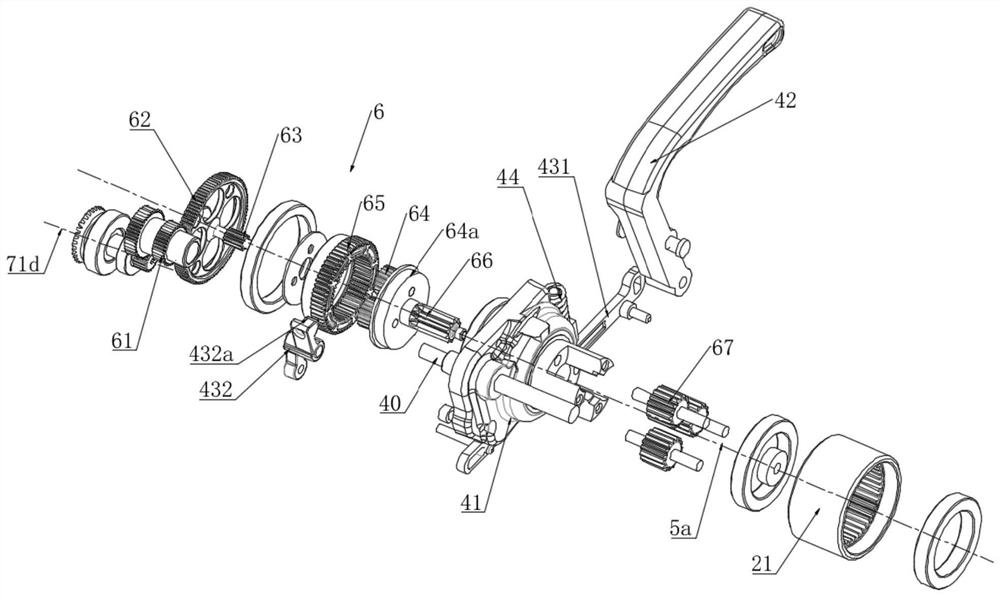

[0064] Such as Figure 1-2 In the shown embodiment, a portable packing machine includes a base 1 , a strap tightening mechanism 2 arranged on the base 1 , a tightening wheel lifting mechanism 4 and a strap welding mechanism 3 . Wherein, the base 1 is used as a skeleton structure for fixing other various structures. The frame 1 includes a base plate 11 arranged horizontally at the bottom and a frame body 12 vertically arranged on the base plate 11 .

[0065] The strap tightening mechanism 2 includes: a tightening wheel 21 driven by rotation, and a tightening plate 22 located below the tightening wheel 21 . The tightening plate 22 is disposed on the top surface of the base plate 11 . The endless binding belt clamped between the tightening wheel 21 and the tightening plate 22 is tightened under the rotation of the tightening wheel 21 .

[0066] The strapping welding mechanism 3 is configured to form a stable friction welding connection at overlapping positions of the strapping...

Embodiment 2

[0115] Figure 17-19 The illustrated portable packer is a variant of Embodiment 1. Different from Embodiment 1, the second driving mechanism 72 in this embodiment is arranged parallel to the first driving mechanism 71 . The plane where the swing bracket 82 swings is perpendicular to the plane where the swing seat 41 (or tightening wheel) is located, and the second drive mechanism 72 drives the swing bracket 82 to swing through the rotation of the eccentric wheel provided on its output shaft, so that the swing bracket The lower swing of the upper pressing column presses toward the welding frame or the upper swing moves away from the welding frame, thereby realizing the switch between the rest position and the welding position of the strap welding mechanism 3 .

[0116] In this embodiment, in order to simplify the structure, the welding state conversion mechanism adopts the following Figure 20-21 structure shown. Only one lower roller 842 is arranged on the swing bracket 82,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com