Process for refitting rudder blade of ship

A rudder blade and process technology, applied in the field of ship rudder blade modification technology, can solve problems such as large curved surface and linear shape, and achieve the effects of beautiful appearance, good quality and precision, and overall linearity and smoothness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The present embodiment provides a ship rudder blade modification process, which includes the following operation steps:

[0058] Step S1: Removal of the old rudder blade:

[0059] 1) Preparation before dismantling:

[0060] a. After the ship is docked, set up a work frame in the rudder blade construction area.

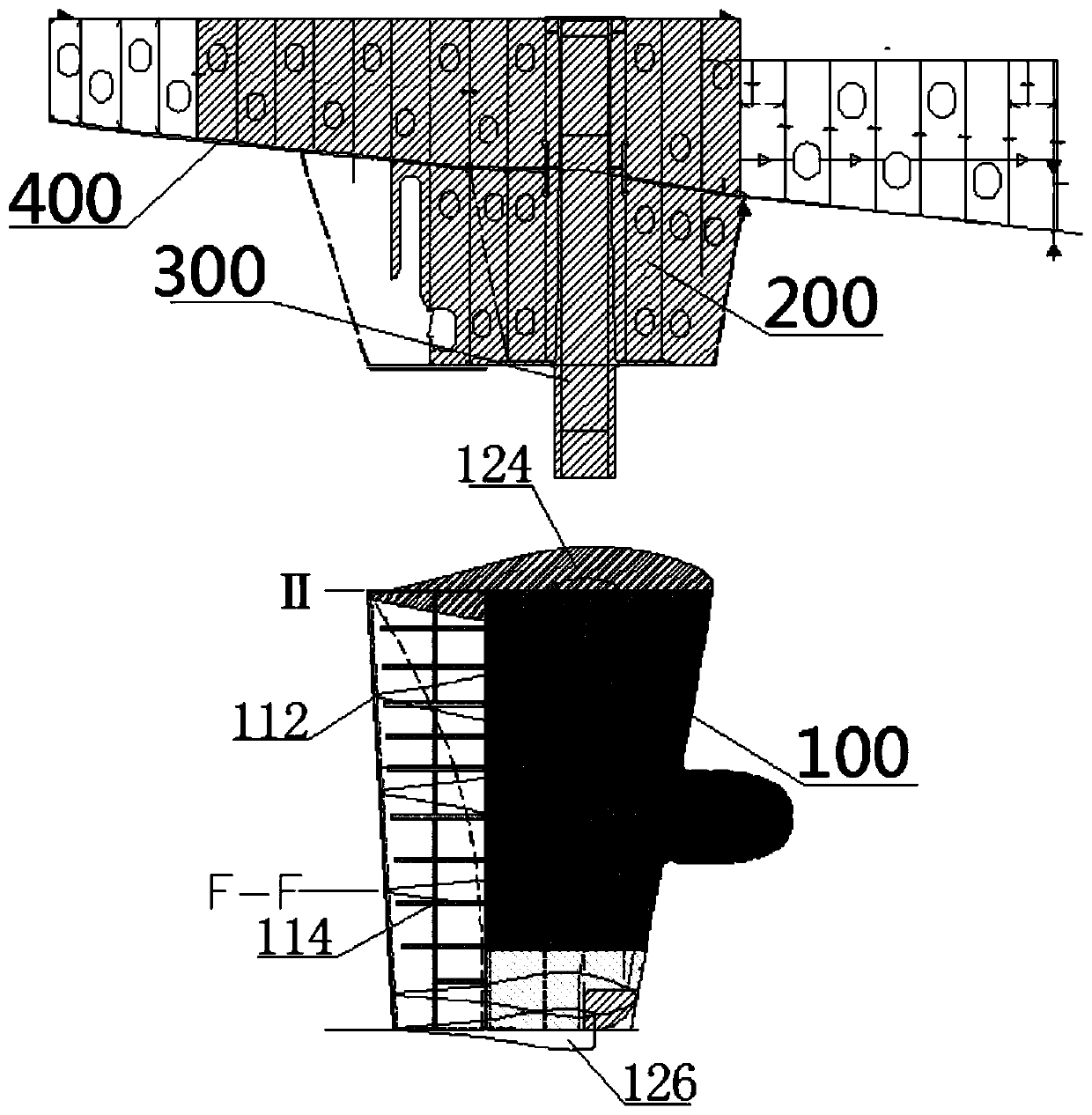

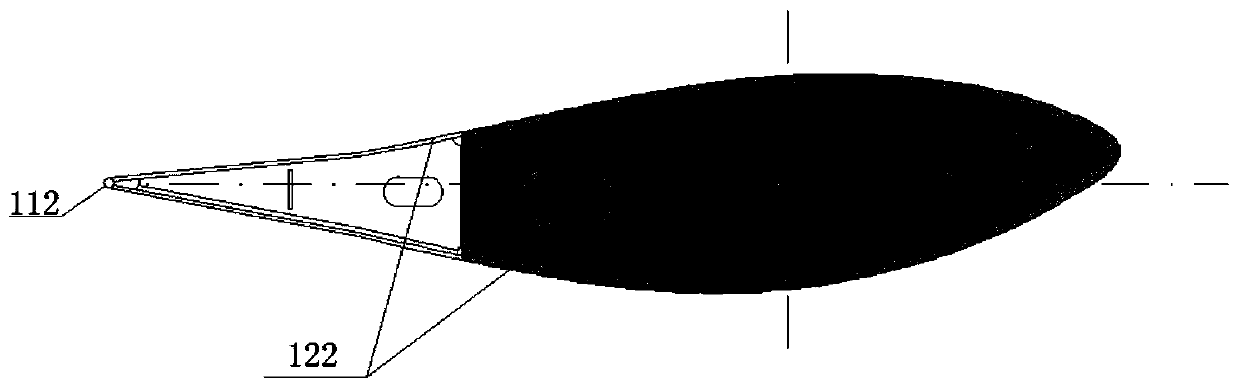

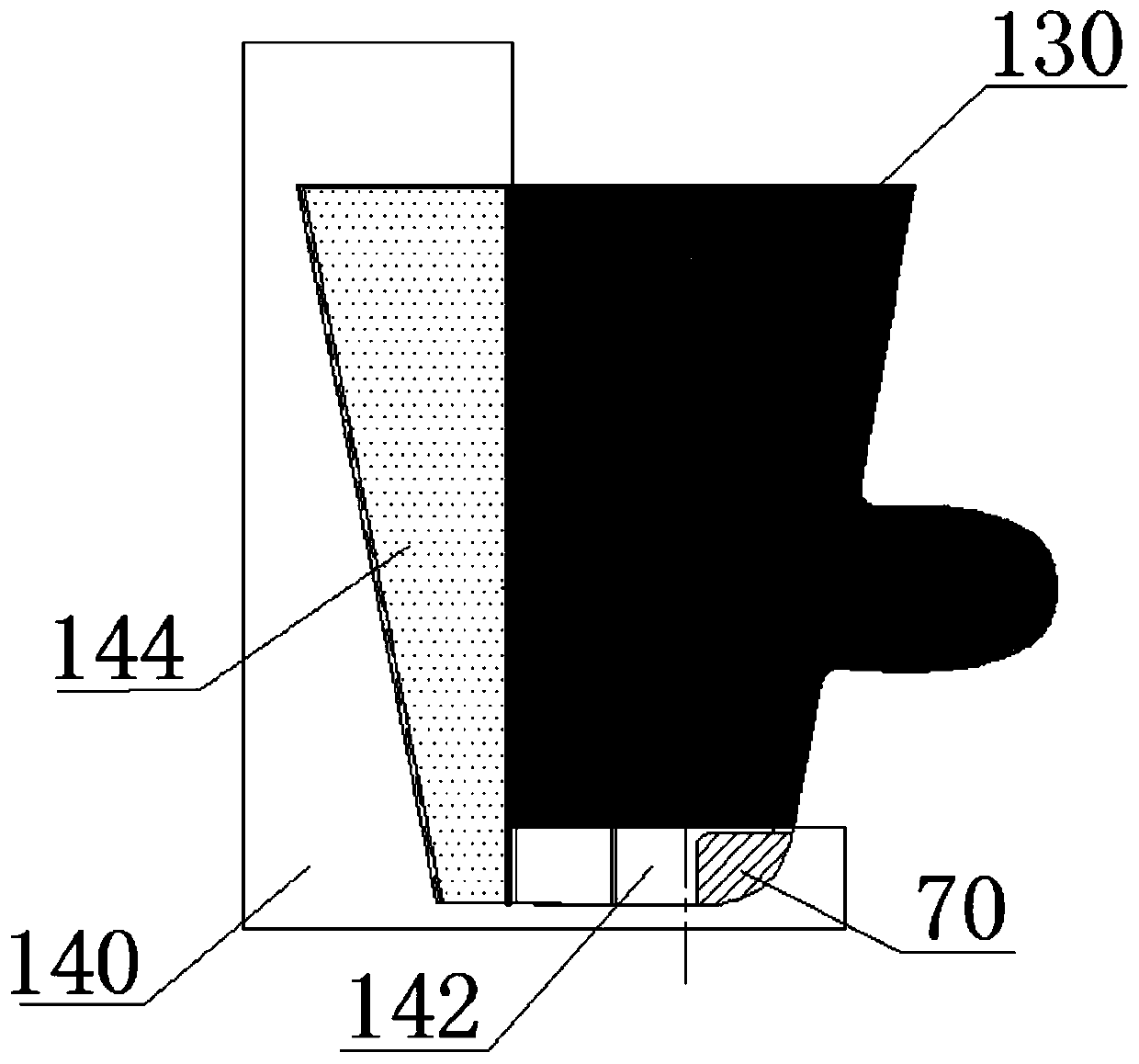

[0061] b. Swing the rudder blade on the ship to zero rudder angle, divide it into sections according to the drawings, and delineate the part of the old rudder blade that needs to be retained and the part that needs to be removed, please refer to image 3 , image 3 It is a schematic diagram of the structure of the old rudder blade modification area. The part that the old rudder blade needs to be retained is the old rudder blade reserved section 130, as shown by the shaded part in the figure; the part to be removed is the old rudder blade removal section 140, the overall side view is L-shaped. Please refer to Figure 4-5 , Figure 4 Retaining the segmented ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com