Gutter connection mechanism and method

A technology of connection mechanism and connection method, which is applied in the direction of building structure, roof, construction, etc., can solve the problems of easy water leakage, easy deviation of aluminum alloy gutter, poor sealing performance, etc., and achieve the effect of improving sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

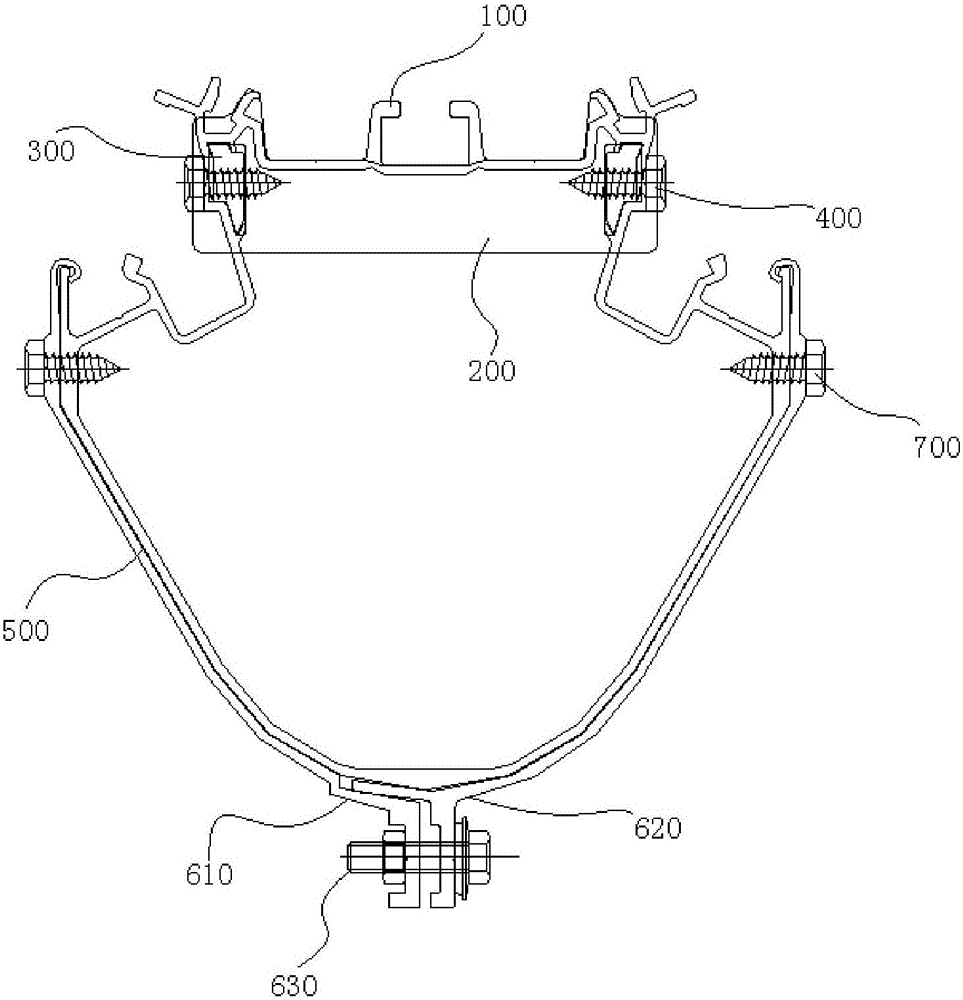

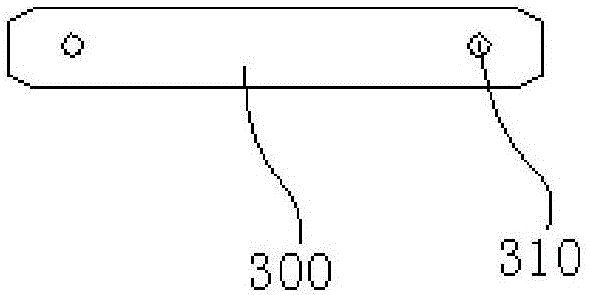

[0032] see Figure 1 to Figure 6 , the gutter connection mechanism provided by the present invention is used to accurately butt two gutters 100 that need to be connected, and it includes a gutter connection sealing sheet 200, two identical gutter connection positioning sheets 300, and a fixing device and sealing device.

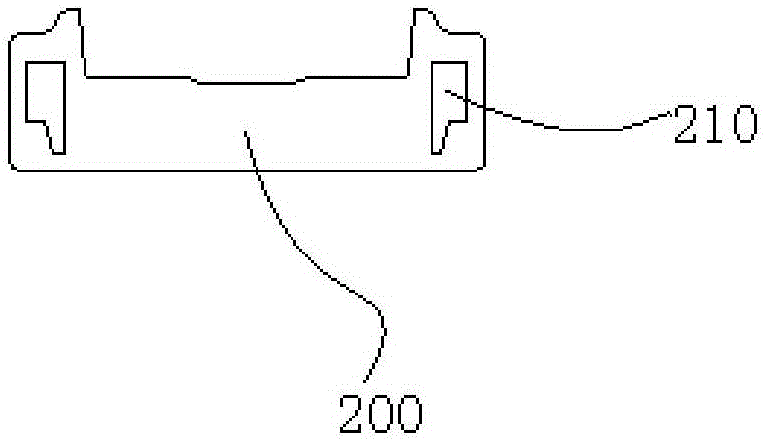

[0033] One end of the gutter connection sealing sheet 200 is mated with one of the gutters 100 , and the other end is mated with the other gutter 100 , which is used to ensure the tightness between the two gutters 100 that need to be connected.

[0034] Two ends of the gutter connection sealing sheet 200 are provided with perforations 210 corresponding to the gutter connection positioning sheet 300 .

[0035] In addition, in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com